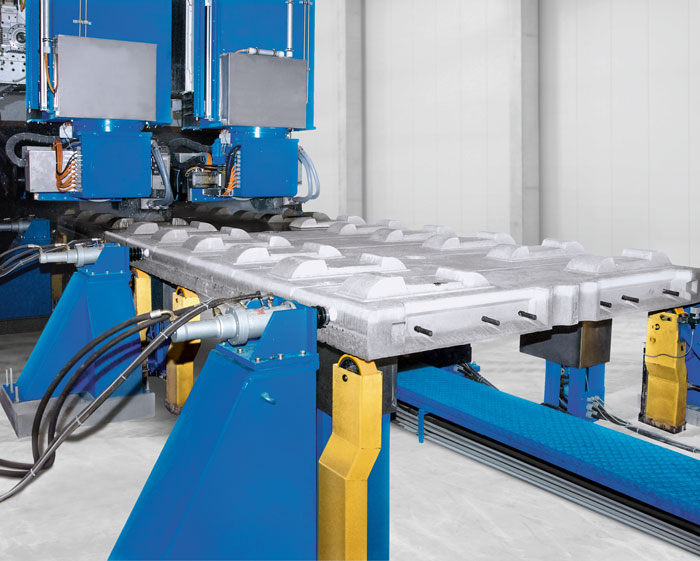

Fixing axles in a grinding machine

Industrial hydraulic cylinder, clamping unit

Nowadays, fixed concrete track slabs are laid on high-speed routes. "With the track elements in prefabricated construction, developed by us for the ICE (Intercity-Express), we work with a precision of 0.1 to 0.2 mm," says Dipl.-Ing. Stefan Bögl, Head of Research and Development at Max Bögl GmbH & Co. KG.

These large elements with considerable mass are produced under controlled conditions in an enclosed fabrication building and achieve a significantly higher quality at the same price than the roadways cast in the open directly in the track bed.

The prerequisite for precise grinding of the finished parts is fixation during machining. With Hänchen hydraulic cylinders and safety clamping via the spring-applied locking unit, a fixation accurate to 0.01 mm is achieved during machining, despite the mass and size of the blanks.

- Energy-saving use of the hydraulic drive

- Cylinders position the component to an accuracy of 0.01 mm

- Dirt protection due to folding bellows

- Hydraulic cylinder and clamping element as a finished unit

- Weight of the track elements: 9 tons

- Ensure precision accuracy of 0.1 - 0.2 mm

- Protection of the drives against grinding dust

- Ability to switch off the hydraulics during the grinding process, with simultaneous exact positioning of the workpiece

- Hydraulic cylinder series 120 for up to 150 bar

- Bore 60 mm, rod Ø 40 mm, stroke 60 mm

- Force transducer

- Proportional valve

- Guiding system: Servoslide® for speeds up to 0.5 m/s

- Clamping unit Ratio-Clamp® with a holding load of 50 kN

- 0.01 mm exact fixation during machining

The manufacturing process

In a first step, the blank made of a special concrete is poured upside down. Two reinforcing meshes provide the necessary strength, one is designed as a flat mesh, the other has a three-dimensional profile. Six steel strands protrude from each side of the concrete slab and can be screwed to the next track element before the gap is concreted on site. After the mould has been cast in the factory, vibrators compact the building material in order to guarantee a material free of inclusions. The track body, which is stripped and also planar on the underside, hardens, whereby the material-typical shrinkage, in contrast to external assembly, takes place under precisely controllable conditions.

The track profile

The exactness required for the assembly of the track girders cannot be achieved solely by precision casting. In addition, the individual elements must have individual shapes, because each one is tailor-made for the corresponding track and terrain contour. This concerns the curve radii, the transition curves, troughs, crests, as well as other terrain contours. Depending on the route, each of the 6.5 meter long and 2.55 meter wide plates can have its own three-dimensional profile.

Precision milling in concrete

A grinding wheel with a width of 200 mm is driven by a 100 kW spindle and grinds the track elements produced with an excess of 2 mm into shape after hardening. 2 meters are processed per minute and up to 2 mm are removed in one operation using a wet process. This prevents overheating and extreme dust development. The spindle applies a cutting force of up to one tonne. In connection with the dimensions and a weight of the track elements of 9 tonnes, there is therefore a risk that the castings to be processed will bend in the 0.1 mm range despite the reinforcement. Although positioning and holding a workpiece in position is actually a simple process, there are therefore framework conditions that place extremely high demands on the linear drives.

Hydraulic Fixation

After the concrete body is moved in via a roller conveyor, six hydraulic cylinders bring it into position. They are all equipped with force transducers. There are three hydraulic cylinders on each side. Three of these cylinders, two on the left at the ends and one on the right in the middle, are equipped with proportional valves and, as linear drives, are part of a control circuit that is controlled via a Siemens 840 D NC PLC. The other three hydraulic cylinders move into the end position, while the three control cylinders position the roadway element with an accuracy of 0.01 mm. All six hydraulic cylinders have a bore of 60 mm, a rod diameter of 40 mm, a stroke of 60 mm and are equipped with proximity switches. As soon as the end position is reached, four more hydraulic cylinders are brought into position for support. Subsequently, six hydraulic cylinders fix the large workpiece from the sides. These are also designed to absorb any lateral forces that may occur on the piston rod. All hydraulic cylinders are from the 120 series, suitable for pressures up to 150 bar and tested to 1.5 times the pressure. The six lifting and holding cylinders and three of the laterally arranged clamping cylinders are equipped with the Servoslide® guiding system. This Hänchen quality is equipped with a special synthetic guide for optimised friction properties. The sliding surfaces of this guide have a vibration-damping effect, prevent edge pressure and ensure largely stick-slip-free movements. The high manufacturing accuracy and small guide clearances guarantee a long service life at piston speeds of up to 0.5 m/s. In addition, four hydraulic cylinders clamp the grinding heads.

Hänchen catalogue cylinders

Bögl uses catalogue cylinders from Hänchen. With investments amounting to millions, the hydraulic specialist has converted the entire design and development to a complex three-dimensional CAD system in recent years, which is specially designed for modular design. The modularisation is so fundamental that each bore contour represents a module that is only stored centrally once. The customer can also access this modular system on the PC in a spatial representation via the online HÄKO product configurator. In this way, the company from Ostfildern near Stuttgart offers a wide range of tailor-made product variants without the costs and uncertainties of a special design.

Clamping unit Ratio-Clamp®

All hydraulic cylinders acting from below and three of those acting from the sides are equipped with the patented clamping unit Ratio-Clamp® from Hänchen. One of the lateral clamping devices of type RCS 40 with a diameter of 40 mm is a special design and has been modified in order to be able to absorb side loads without damage. All clamping units apply a holding load of 50 kN as soon as there is no more pressure on the hydraulic system. They thus permit machining with a pressureless fluid circuit. The clamping unit Ratio-Clamp®, which has also been tested by TÜV, performs safety-relevant tasks in production, for example, as the clamping is only released when pressure is applied. In this switching state, the rod can be moved freely in both directions. A pressure drop releases the energy stored in disc springs, which applies the holding load to the rod via a conical clamping element. This process can be triggered automatically by a targeted pressure drop from the control system, but also in the event of a power failure or system damage. The clamping force is maintained without energy supply for any length of time until the releasing pressure is applied again and the piston rod is thus freely movable. Even if the rod is occasionally pushed through over short distances when the specified holding load is exceeded, the system is not damaged. This makes it possible to hold the concrete element exactly in position without hydraulic pressure or control during the half-hour machining time. The clamping unit Ratio-Clamp® is available as standard as a complete unit or in combination with a hydraulic cylinder. The customer can create this solution in the electronic catalogue using a scaled CAD object with all mounting dimensions, convert it and export it as a 2D or 3D data record, for example in Autocad format.

A successful cooperation

After milling, the concrete elements receive an identification number in order to install the correct beam in the correct location. The "Feste Fahrbahn Bögl" (Bögl solid carriageway) is being laid for the first time over a total of 70 km, an innovative project that is part of a diverse portfolio: the range of the third-generation Franconian family business, which employs 4,000 people and generates sales of 750 million euros, ranges from prefabricated houses to turnkey football stadiums for the World Cup.

New paths with concrete

With the production of the "Feste Fahrbahn" (solid carriageway), Bögl and Hänchen are demonstrating that completely new paths are possible in the processing of concrete: the use of even large components as precision products. Both companies were able to bundle their expertise in this project: The hydraulics specialist is demonstrating the high performance and precision of its hydraulic cylinders even under harsh environmental conditions, as well as the possibilities of modular design and product systems, which also solve demanding tasks without special designs and the solution approach of a complete hydraulic axis including safety clamping by means of a locking unit. "For us, the cooperation during the development period from September 2002 to October 2003 and the production that has been running in three shifts ever since has proven its worth," confirms Stefan Bögl. And the family business is thus exemplarily demonstrating completely new perspectives for components with its own research and development division, which are produced under exact environmental conditions with previously unknown precision and repeatability. Despite the crisis in the construction industry, the company has so far been able to secure both its jobs and its black figures with this innovation and complete solution concept.

© Hänchen 2005