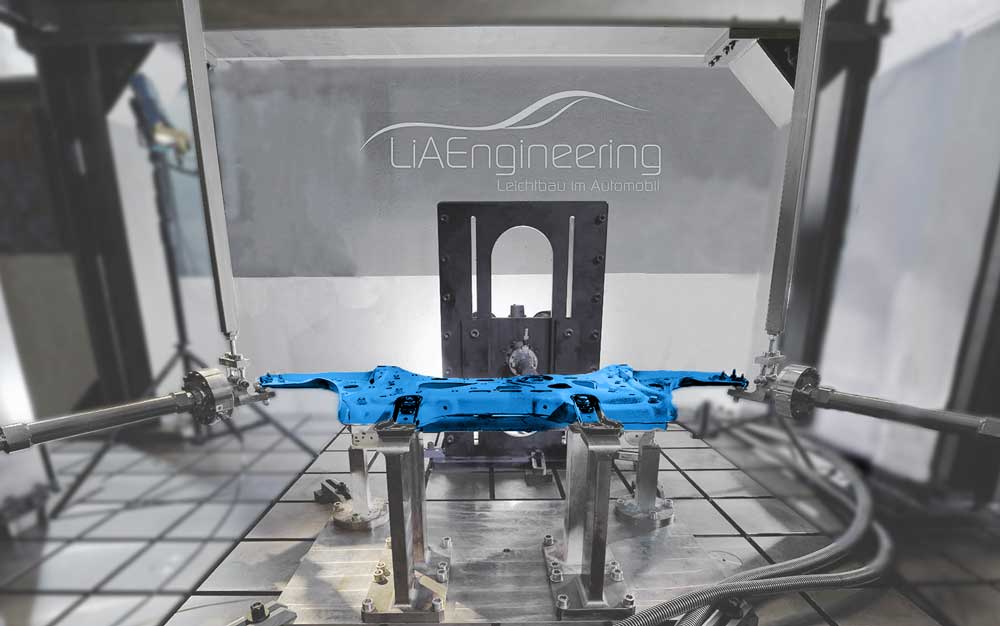

Test Field Design & Equipment

Highly dynamic testing of lightweight design components

Machines, vehicles and aircraft are becoming increasingly energy-efficient and therefore designed with lightweight design principles. For this purpose, many components have to be redesigned and tested. LiA Engineering designs and implements efficient lightweight structures for its customers and then tests them extensively. The company has built a test centre to optimally respond to a wide variety of test requirements.

LiA sought support from Herbert Hänchen GmbH, who were involved from the outset in the design and construction of the modular test field - especially in the area of safety technology and system integration. “We would bring Hänchen on board again at any time for the development of further test centres,” emphasises Dipl. Wirt.- Ing. Simon Pöhler, Managing Director of LiA Engineering GmbH.

- Adaptability to your projects

- Use of existing components of the customer

- Fast and reliable customer support

- Technical expertise

Test bench requirements

- Testing of structural components under static short-term loads and dynamic long-term analyses

- Support for the design and construction of the test field

- Design and implementation of a safety concept according to MRL

- Contact person for general questions about hydraulic and port topics

- System integration of various new and existing components at LiA

- Test Actuator for up to 320 bar with forces of 25-750 kN

- Conceptual design and implementation of the safety control system

- Safety technology according to EN ISO 13849-1 with PLe

- Consulting and review of the necessary degree of technical detail

LiA Engineering was founded in 2015 as a spin-off of the “Lightweight Construction in Automotive Engineering" chair at the University of Paderborn and continues to actively maintain this relationship to this day. The business areas include consulting, engineering, prototyping and testing. For example, the company advises on innovation management and the use of new materials for lightweight structures and takes over the design and simulation of the components through to series production. For the latter, there is a joint venture as “LS Hybrid Solutions GmbH" with BuL and Schwarz Werkzeugbau. There is a high level of expertise in the field of testing structural components for the automotive and aerospace industries. Even finished components from companies that do not have their own testing facilities or experience can be tested. To this end, LiA develops application-specific test scenarios for the respective components and then builds the appropriate test environment for them. These tests range from material testing to component testing. In order to be able to cover this range of tasks, LiA employs both young, innovative, often doctoral employees and analysts who have been active in the industry for over 40 years and score points with their experience.

Requirements for the test field

A test centre with many possibilities

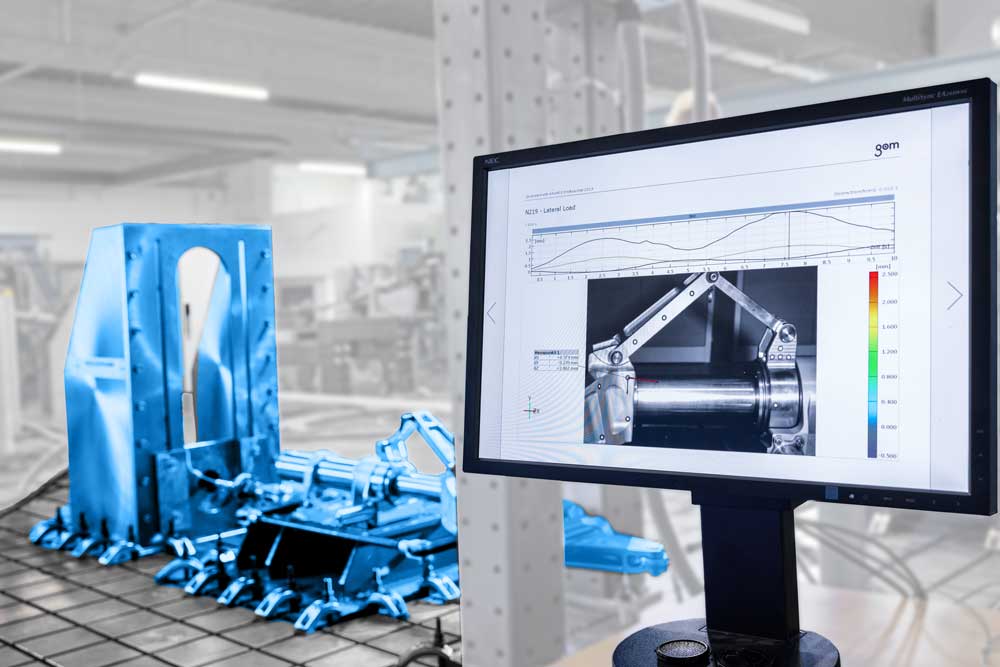

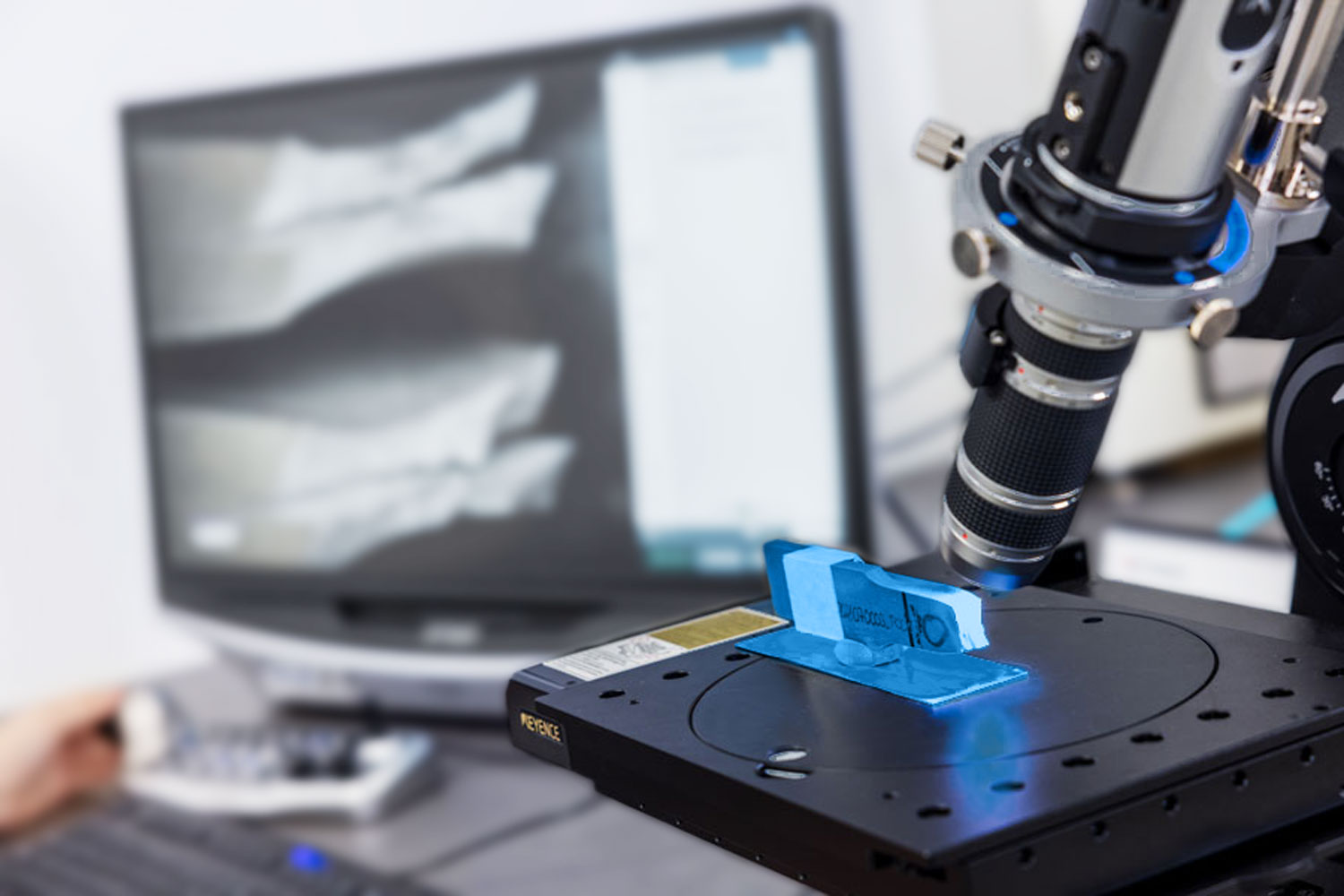

As an accredited service provider, LiA Engineering and its test centre offer the possibility of carrying out highly dynamic tests on components and material characterisations. In terms of measurement technology, all physical quantities such as force, displacement and others can be recorded synchronously. High-speed cameras can be used to measure components optically, from microscopic to macroscopic. The simulation of operating conditions is realised via the flexible clamping range, in which hydraulic cylinders apply loads to the component from the outside. A climatic chamber makes it possible to simultaneously generate environmental influences such as humidity and temperatures from -60 °C to +120 °C. Static short-term loads and dynamic long-term analyses are therefore possible under optimally simulated real conditions.

In addition to prototype tests, series-accompanying tests are also carried out. LiA also supports companies that, for example, require efficient tests to solve material problems. The Paderborn-based company can deliver initial results of material characterisation within 24 hours. "This fast reaction time to a wide range of requirements is only possible thanks to the extremely flexible employees and the modular principle of the test setups," emphasises Pöhler.

Individual solutions for test requirements in various industries

Material characterisations are particularly important for customers from the automotive and aerospace industries, but also in the agricultural machinery or medical technology sector. These customers are looking for a solution to their problem: Either they know how it needs to be tested and require external testing capacities or they know the failure of the component and are looking for support in analysing the cause of the failure. This requires highly dynamic tests with measurement results certified in the test laboratory. In order to guarantee the measuring accuracies defined by the customer, LiA - like the institute at the University of Paderborn before it - has been relying on test actuator from Hänchen for years. The testing accuracy and the available spectrum of cylinders built according to the requirements are therefore optimally covered, because “everyone who has other cylinders raves about Hänchen cylinders", Pöhler is convinced. Because of this high accuracy, quality and reliability, Hänchen supplies 100% of the entire test actuator stock at LiA. The collaboration with Hänchen was already very good in previous years – in particular with regard to coordination, support and, of course, the quality of the services provided. LiA therefore also relied on the support and advice of the specialist for hydraulic systems when developing its new test centre.

Construction of a modern, highly professional test field

Hänchen, a reliable partner in hydraulics

Within the scope of special machine construction Ratio-Drive®, Hänchen designs individual special machines tailored to the customer's needs, particularly for test engineering. This offer extends to the realisation of complete test machines including design, hardware and software. The customer can also commission partial solutions in which Hänchen only takes on selected tasks, supplementing the existing, customer-side modules to create a complete machine. The company from Ostfildern near Stuttgart was therefore involved in the project planning phase for the test centre at LiA at an early stage: this included the design of the safety control system and the selection of cylinders, as well as a great deal of supporting knowledge in the realisation of the project.

Hänchen supports with consulting, software and components

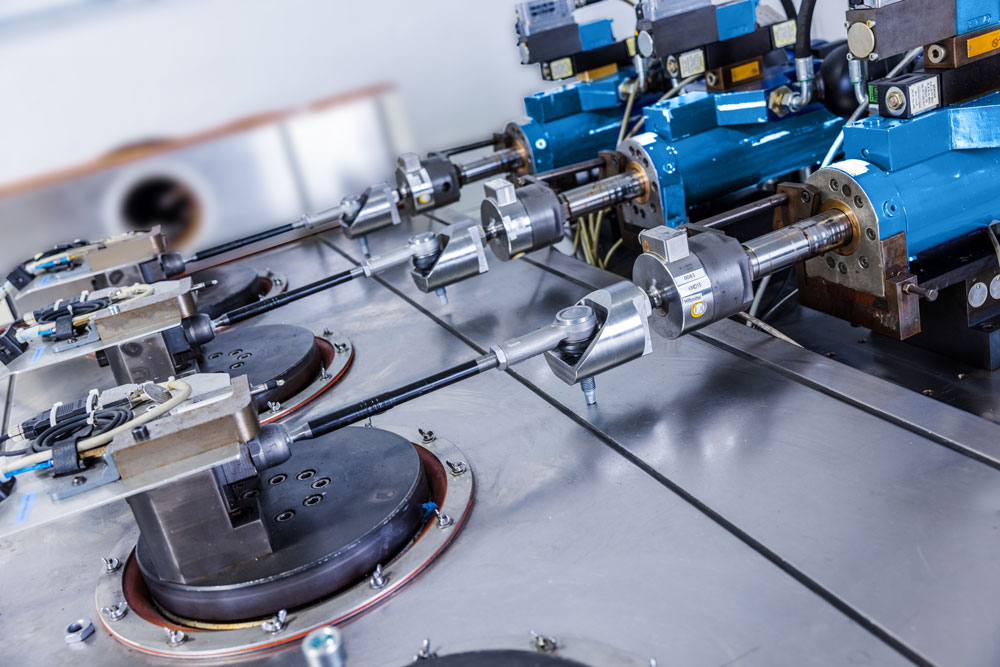

LiA Engineering uses components from a wide range of tried-and-tested manufacturers in its test centre. The task was to combine these into a functioning system. Hänchen took over this system integration with a safety control system developed in-house, which monitors all components, such as the power unit, cooler, control of the cylinders, evaluation and control software. This higher-level control system has control over the clamping range and, for example, uses position-monitored valves and switch-on-blocks designed individually for LiA to implement a hydraulic shut-off in accordance with EN ISO 13849-1 with Performance Level e (PLe). Hänchen also implemented this safety technology as well as the final CE certification. LiA has thus realised the highest safety standards in the test field.

A special feature of Hänchen are hydraulic cylinders with a working pressure of up to 320 bar for use in testing applications. Other manufacturers sometimes only offer these with a working pressure of up to 210 bar. The advantage of the higher working pressure is evident in several points:

- Compact construction. Dynamics. Stiffness

In order to apply the same cylinder force, the working areas can be smaller with a higher working pressure. This makes the cylinder more compact, which makes the entire system significantly more dynamic and rigid. - Smaller valve

The required flow rate is also lower, which means that a smaller valve can be used. - Cost efficiency. Space-saving.

In addition to cost savings, this also results in installation space advantages for the entire hydraulic periphery. - Hänchen test actuator

LiA exclusively uses Hänchen cylinders and is equipped with forces from 25 kN - 750 kN for a wide variety of testing requirements.

In addition to programming the safety control system and equipping it with hydraulic cylinders, the experts from Ostfildern were also intensively involved in the engineering and design of the test field. The necessary degree of detail of the technical and application-specific solution was checked and adapted to the application. Hänchen was also on hand with advice and support for general questions relating to hydraulics and ports. "And even today we are in close and cooperative exchange with Hänchen, because there we have the best support and always get the right solution for the application," says Pöhler.

Jörg Beyer, mediaword

© Hänchen 2022