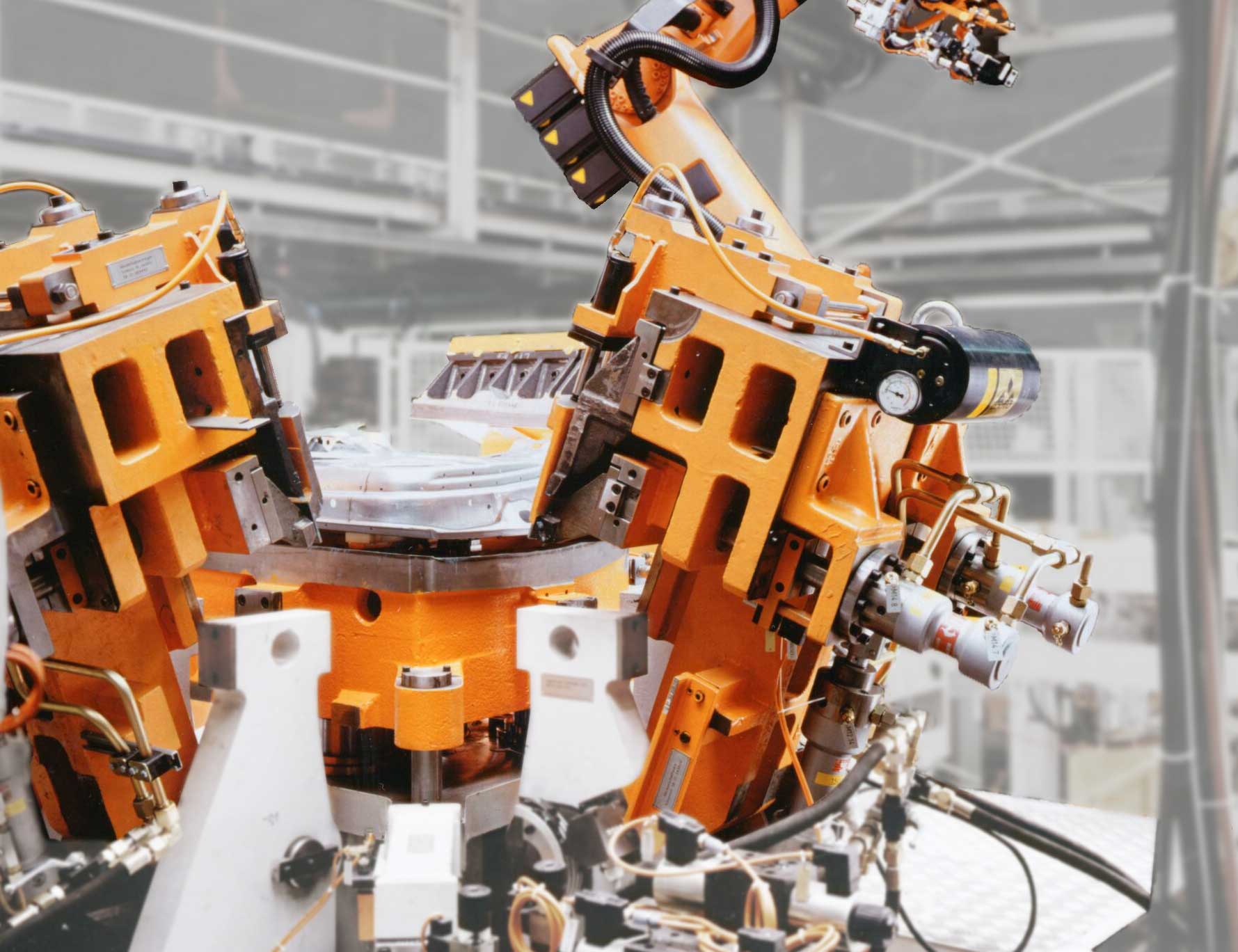

Folding machine for the automotive industry

Industrial hydraulic cylinders, standard cylinder DIN/ISO

IIn series production, folding offers numerous advantages over welding: It is a joining technique that can be used in visible areas without rework. The joining technology alone allows for sealing and the associated corrosion protection. Any metal can be folded, including aluminium car body parts, which would otherwise require a great deal of additional work to weld.

Hänchen hydraulic cylinders as a plug-and-play unit. 13 standard cylinder DIN/ISO run non-stop in up to 27 shifts per week. Due to the reliability and long service life of the Hänchen cylinders, Audi can avoid storing spare parts.

- Long service life of hydraulic cylinders

- Fast spare parts service

- On-site consultation

- Precisely operating cylinders

- Pressure of 100 bar at 80 N/mm

- Reliable hydraulic cylinders

- Dimensional accuracy of only ± 0.2 mm

- Folding time of 20 seconds

- Series 120 hydraulic cylinders

- Standard cylinder DIN/ISO with mounting dimensions according to ISO 6020-1 series 160

- Sealing system: Servocop®

The main players in this process are 13 Hänchen hydraulic cylinders from the catalog range. Since 1991, the Audi toolmaking division in Ingolstadt has been using the products of the hydraulic specialist from Ostfildern near Stuttgart in its hemming systems. Throughout the VW Group and beyond, these hemming systems connect the outer and inner parts or the welding groups of doors, front and rear hoods, and side wall frames without welding. "The hydraulic cylinders are a core component that is subject to the highest demands," is how Dipl.-Ing. (FH) Ernst Beringer from Audi toolmaking describes the requirements. "As a drive with high force and precision, they have to work non-stop for 15 to 17 shifts per week. Initially, we used tie rod cylinders for this task, but they did not meet our requirements for stability. We have been using Hänchen hydraulic cylinders for nine years and are very satisfied with them." This is reflected, for example, in the fact that no spare parts are stored for hydraulic cylinders. There is not even a stock of seals, as Hänchen guarantees a worldwide service with 24-hour delivery time for these components. In this way, the toolmaking division of Audi AG supplies VW companies at home and abroad as well as overseas, despite strong competition, and also produces hemming systems for other suppliers of car body plants. With the understanding of a system supplier, Beringer says, these hemming systems meet the high quality requirements of customers.

Plug-and-play unit from HäKo

The hydraulic cylinder is a plug-and-play unit for the system manufacturer, which, as a Hänchen standard cylinder DIN/ISO, is manufactured with such dimensional accuracy that it can be replaced at any time and worldwide within the maintenance shift on Sunday. To simplify matters, only three types are used, which Beringer and his team select and order using the Hänchen Konfigurator HäKo. This allows the standard cylinder DIN/ISO to be optimally adapted to the respective installation situation. In addition, the HäKo enables economical purchasing and guarantees the shortest possible delivery times. "This is where quality and economy begin in procurement," says the designer.

The use of hydraulics

The quality of a hemming is particularly determined by the hemming radius: the tighter, the better. To achieve this, the Audi engineers proceed in the following steps: The outer part, whose flange is open to approximately 90 degrees, is inserted into the hemming system and positioned exactly. A robot adds the welding group to be joined as an inner part. Hydraulic cylinders close the C-brackets with the hemming jaws and bring the pre-hemming jaws into position for the first hemming step. Another hydraulic cylinder moves the hemming bed vertically upwards and then generates the necessary pressure to close the hems to an opening angle of 45°. Now the pre-hemming jaws are hydraulically retracted again. The hemming bed continues to move against the finish-hemming jaws and closes the hems with a correspondingly high pressure of 100 bar at 80 N/mm calculated on the hemming length. In this way, the system achieves the required small radius of curvature. Finally, the C-brackets are opened again, the hemmed part is removed from the hemming system and further processed in the corresponding manufacturing process.

Third generation hemming systems

The idea of bringing the pre-hemming jaws into engagement via a slide function has made the hemming system significantly more compact and less expensive. In the first generation, pre-hemming was carried out in a 5-meter high press, and finish-hemming was carried out in another unit of the same size. In the second generation, the hemming jaws were mounted one above the other in two separate groups. The process was now carried out in a system with a height of 2.2 meters. The new third-generation systems with the C-brackets have been in use since 1998 and are only 1.6 meters high. This optimization of the movement sequences results in the aforementioned short hemming time of 20 seconds.

Hydraulics – an essential basis for high precision in hemming systems

High-quality hydraulic components create a key prerequisite for meeting customer requirements for a hemming system. This is because they apply the necessary forces and allow a high degree of precision in the movements and positioning, according to the experience of Audi toolmaking. "With Hänchen, we at Audi have a proven partner. With precise hydraulic cylinders with maximum availability in compact hemming systems, we can achieve gap dimensions that meet the world's highest quality standards," Behringer is convinced.

© Hänchen 2001