Components for hydraulic test stand technology

Hydraulic cylinders, hydraulic control blocks, test fields & test machines

The selection of the right components for hydraulic test stands is decisive for the optimal operation of a test machine.

This starts with machine elements for jig construction, drive elements such as hydraulic cylinders or hydraulic test actuator for linear movements and extends to safe control, which is implemented with the help of electronic controls and hydraulic control blocks.

Hänchen manufactures many components for test stand technology and also offers the implementation of complete, custom test machines.

Managing Director and Head of Sales

Herbert Hänchen GmbH

- Tailored to your application

- Floating gap seal for friction-optimized use

- Servoseal for reduced leakage on the piston

- Control blocks for your safety

Machine elements

For setting up the test stand

Various machine elements are required in a machine for mounting, moving or securing. Hänchen offers a selected range of special machine elements:

Coupling rods and shafts

Do you need special machine elements for your test stand that are adapted to your requirements? Hänchen produces individual pieces and small series of rods, shafts and axles according to your specifications.

Mounting elements

The connection of test specimens to the drive elements and to the test setup must be dimensioned according to the requirements. For this purpose, the dynamic and static loads such as forces or accelerations must be taken into account both in the load direction and transversely to it.

Hänchen offers the appropriate mounting elements for this. You can find out more about this under Mounting elements.

Load holding devices

The EU Machinery Directive requires a risk assessment. The implementation of these requirements is preferably carried out constructively or via control engineering measures. Loads that can experience lowering/sinking due to emergency stop, power failure, temperature differences or leakages must be structurally secured.

Hänchen offers the Ratio-Clamp® clamping unit for this purpose. You can find out more on our product pages for the clamping unit.

Pressure chambers and seal bushings

For testing of components under fluid pressure, appropriate pressure chambers are required. These either completely enclose the test object or guide the test object, for example a shaft, to the outside. The movement is applied from the outside.

The seal at the feedthroughs must be designed for the hydraulic pressure, and the chemical-physical resistance of the fluid must also be taken into account.

Hänchen manufactures individual sealing systems and guiding elements for your requirements; if required, we can also take over the engineering of these components for you.

Drive elements

For the test setup

Hydraulic or electric? The appropriate drive technology results from the application and environmental conditions as well as from the requirements of the motion profile. Hydraulics offers you the following advantages:

Simple generation of very large forces

- High power density

- Compact construction

Low inertia resistances

- Start-up from standstill at full load

- Simple reversal of the direction of movement

High positional accuracy

- Fast, sensitive, uniform and stepless adjustable speeds

- Simple control concepts with strongly varying performance requirements

High service life despite continuously and simultaneously available power

- Force (~ depending on the pressure)

- Speed (~ depending on the flow rate)

Hydraulic drives

From Hänchen

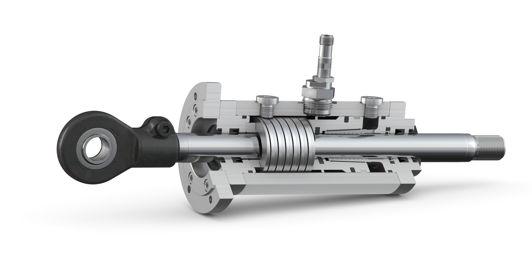

servo hydraulic actuator

Hydraulic servo hydraulic actuators are ideal for static testing tasks and tests up to 25 Hz. These linear drives are also particularly suitable for testing tasks with long strokes. You can find out more on our product page for servo hydraulic actuator.

Pressure intensifiers

Hydraulic pressure converters translate a fluid pressure to a higher or lower value. If the transmission ratio is greater than 1, it is called a pressure intensifier, if it is less than 1, it is called a pressure reducer.

Pressure intensifiers are used to generate very high pressures. Applications include, for example, test applications for internal pressure burst tests or dynamic pressure tests.

Learn more about our pressure intensifiers & fluid separators.

Test actuator

Hydraulic test actuators are ideal for highly dynamic tests with high frequencies and small amplitudes. These linear drives are available as light and heavy versions for high inherent stiffness. Read more about our test actuators here.

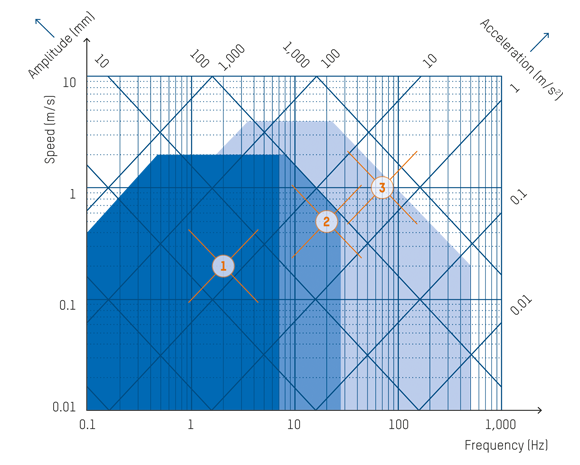

Selection of the right hydraulic cylinder

Based on the dynamics of the motion profile

Which hydraulic cylinder is the right one for your application depends on various technical criteria such as:

- frequency

- Amplitude

- Speed

- Acceleration

- Control engineering behaviour

Use our HÄKO product configurator for assistance in designing the right hydraulic cylinder or test actuator.

![]() Double-rod cylinder series 320

Double-rod cylinder series 320

![]() Double-rod cylinder series 120 and 300

Double-rod cylinder series 120 and 300

![]() Single-rod cylinder series 120 and 300

Single-rod cylinder series 120 and 300

Control

Simply safe

The technological parameters for the movement and the requirements from the EU Machinery Directive require suitable control components. This is achieved with the help of electronic controls in combination with hydraulic control blocks.

Hydraulic control blocks

Control blocks or so-called valve blocks are used in test machines for different tasks. Different functions can be compactly combined with one another in one block via mounted and built-in valves, without additional lines.

Hänchen takes over the engineering and implementation of the control blocks. Functions can be:

- Switching on, for jerk-free and impact-free start-up

- Shutting off, to separate cylinder chambers or drive axes from the fluid supply

- Set-up mode, for traversing at reduced speed

- Short circuit of the chambers, for control engineering damping optimisation or for deactivating load

- Fluid distribution, for distributing the fluid flow to various consumers

- Accumulator port, for mounting hydraulic accumulators

Individual software for test stands

Through automation with electronic components and software, a hydraulic system can map complex processes. Furthermore, safe controls can be implemented with it.

The software, in combination with standard software elements and individual modules, is precisely tailored to your application.

- Automation of motion sequences

- Implementing complex control circuit structures

- Realisation of safe controls

You can find out more under Software.

Systems

Test stand, test machine according to EU regulations

Test stands and test machines must be designed in accordance with the EU Machinery Directive. This applies to all machines placed on the market, including machines for in-house use in development and testing centres.

Therefore, the relevant conformity assessment procedures for complete or partly completed machines must always be applied.

Hänchen offers the implementation of complete, individual test machines as well as the design of individual modules or partly completed machine for installation in machines.

Here you will find application examples for Hänchen test stand construction

Functional test stand Ratio-Drive® - End of Line test stand for hydraulic products

Test machine Ratio-Drive® - Test stand for seals and rod surfaces

Hydraulic test cylinder as test actuator - large bearing test stand for wind turbines

Test stand Ratio-Drive®, test actuator - Hydraulic pulse test stand for simulating flight conditions

Test actuator as hydraulic test cylinder - material test stand for long-term tests of aircraft