Die casting machines in the foundry

Industrial hydraulic cylinder

Eleven fully automatic casting centres with integrated robot for deburring the cast components form the core of the die casting department at Auto Heinen. They operate with a closing force of 220 to 630 t. In addition, there are two 600 t casting centres without automatic deburring. Here, modules and special die-cast components made of aluminium alloys are produced.

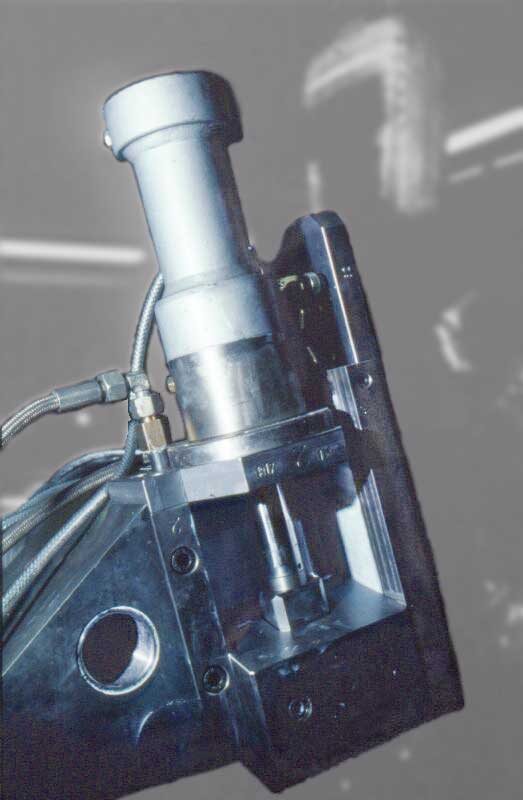

A component that has to meet the highest requirements is the hydraulic cylinders on the die casting plants, which move the plungers and slides of the moulds and other heavy components precisely and with great force. The company from the Eifel region has long relied on hydraulic cylinders from Herbert Hänchen GmbH from Ostfildern near Stuttgart.

- Seals for high thermal stability

- Cylinders for various hydraulic fluids

- Systems for low friction and wear

- working pressure up to 300 bar

- Positioning 50 kg heavy plungers

- Casting pressure between 400 - 600 bar

- External temperature at the hydraulic cylinder of 70 °C

- 100,000 shots with a cycle time of 30 to 60 seconds

- Hydraulic cylinder series 120 (150 bar) with dimensions of 80/40/60 and 100/50/80 [piston/rod/stroke]

- Hydraulic cylinder series 300 with dimensions of 80/50/40 and a rod extension on the left by 18 mm

- Suitable for HFC fluid, temperature up to +200 °C

- Pressure intensifier with dimensions of 40/30/100

The actual die casting shot

Now, the up to 50 kg heavy punches of the mold are first positioned by the Hänchen hydraulic cylinders and the die casting mold is closed by the casting machine. Then, for each shot, the filling chamber of the die casting plant is charged with the required amount of metal by applying compressed air to the liquid metal surface of the dosing furnace. Subsequently, the liquid metal is pressed in during the 'shot': Pressure is applied to the so-called casting tablet via the piston rod of the casting machine's injection cylinder. This filling chamber for the liquid metal is connected via the casting channels to the mold cavities, which are thus kept under pressure with the liquid alloy. In this way, the alloy enters the mold cavity formed with the slides and cores under defined pressure and temperature conditions. Here, the blank for the actual die-cast article is created as it cools. In the case of the steering housings, the pasty aluminum alloy is re-compacted, squeezed, via a punch, which is also operated by a hydraulic cylinder from the Swabian hydraulic specialist. The shot then cools with the mold closed. The mold opens and a robot removes the respective shot. It places the shot in a cutting tool that cuts off the tablet, the overflow beans and channels. Depending on the order and plant, the parts are delivered to the customer as a blank, semi-finished or finished product.

Up to 1000 bar counter pressure on the hydraulic cylinder

In this field of application, several specifications result for the hydraulics: The ambient temperature is high in the vicinity of the liquid metal and the molds. The specific casting pressure generated in the mold is 400 bar. For technical parts it is 600 bar and for steering housings and other pressure-tight parts 1000 bar. This casting pressure exerts a hydraulic force on the mold via the liquid metal. The Hänchen hydraulic cylinders are thus subjected to a hydraulic counter pressure. Since the holding plates of the hydraulic cylinders cannot be attached centrally to the die casting mold for design reasons, lateral forces cannot be avoided. Problem areas are therefore the seals due to the thermal stability, the piston rod guide due to the side loads and the passive pressure resistance of the entire hydraulic cylinder due to the counter pressure.

Problematic framework conditions

“Hänchen has proven itself excellently under these problematic conditions,” says Mahlberg. “If problems did occur, they were caused by thermal overload on our part. And especially since the use of Viton seals and the new Teflon lip seals, seal wear is no longer an issue.” The self-designed but externally manufactured casting molds, which are maintained and repaired in the company's own workshop, are now designed in such a way that they subject the hydraulic cylinders to a maximum external temperature of 70°C. In thermally particularly critical areas, additional spacers or cooling rings are used to minimize heat conduction between the die casting plant and the hydraulic cylinder. Auto Heinen has gained extensive experience here: “The most extreme example was a hydraulic cylinder whose seals attracted attention with an unexpectedly short service life. An inspection revealed that the hydraulic cylinders were subjected to extreme thermal loads. This problem could be eliminated with the simplest means by rearranging the heating system. But overall, the thermal stability of Hänchen products is a central plus point,” the Die Casting Production Manager summarizes. Hydraulic cylinders from Ostfildern are also used by the manufacturers of die casting machines to position the machine column and the locking nut.

Durability of the hydraulic cylinders

The casting molds are each designed for the production of 100,000 shots with a cycle time of 30 to 60 seconds. The hydraulic cylinders withstand this load without seal changes, emphasizes the die casting specialist: “We also had good experiences with products from other manufacturers in the early stages. However, the service lives were drastically shorter, with heat loads and lateral forces leading to excessive wear.” The foundry uses almost only catalog cylinders of the 120 series from the electronic catalog E-Kat (today Product Configurator HäKo) from Hänchen, which operate with a working pressure of 150 bar. They have been modified for ambient temperatures up to a maximum of 200°C by special seal combinations and leak oil port and are suitable for HFC fluid. Apart from this small modification, it is an inexpensive standard cylinder DIN/ISO. For space reasons, one hydraulic cylinder is a custom design, another operates via a pressure intensifier with 300 bar. Due to the specific casting pressure, which is applied to a particularly large mold surface on the slide, forces of 56 t occur. This force is held exclusively by the Hänchen cylinders, into which a check valve has therefore been integrated, which can be hydraulically unlocked.

Ordering with the HäKo

Orders are placed at Auto Heinen exclusively via the Hänchen configurator. The unanimous verdict: Much more practical than a paper catalog. After 100,000 load changes, the seals are replaced and the hydraulic cylinder is used again. If the corresponding mold is no longer used, the hydraulic cylinders are stored and reused for new molds if required. It is crucial for Mahlberg that he can still get replacement seals for 20-year-old hydraulic cylinders in the shortest possible time using the product number, which of course consist of modern materials such as Teflon.

The products

With the help of hydraulic cylinders, particularly vibration-resistant unit holders for engine, transmission and other units, hydraulic parts such as adapters, cooling water regulators, clutch release and steering housings, pump covers and control pistons, complex housings for camshaft bearings and cylinder heads as well as switching confirmation parts such as shift forks, rockers and actuators are produced. In addition, there are pedal bearing blocks, internal gears, planetary carriers and balance shafts as modules. These areas of application place extraordinary demands on pressure tightness, strength, wear resistance and complexity, standards that are reflected in the requirements of the automotive industry. Heinen has customers here such as Ford, DaimlerChrysler, Volkswagen, Porsche, Visteon, INA, Bosch, Mahle, Getrag and LuK. They demand parts that can easily withstand a service life of 200,000 car kilometers. Auto Heinen expects the same quality from its suppliers, which is why Hänchen cylinders are standard in Bad Münstereifel.

© Hänchen 2001