Hydraulic test stand for simulation of flight conditions

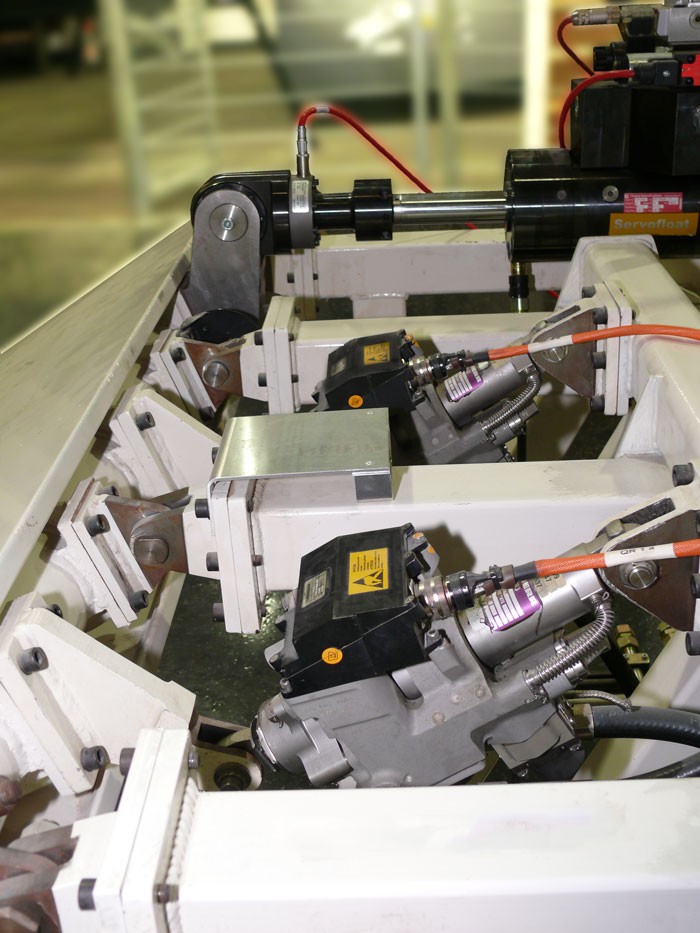

Test stand Ratio-Drive®, test actuator as hydraulic test cylinder

The demands on system reliability in commercial aircraft, especially in the area of the flight control system, are very high, as the failure of systems during flight can have catastrophic consequences. The DLR - German Aerospace Center - at the Institute of Flight Systems Technology is working to further increase the safety of systems and to ensure a safe termination of the flight even after unforeseen events.

Hänchen supplies the entire linear drive system of the Hydropuls test stand for two elevators, one aileron and one rudder. In order to put the aircraft hydraulics through their paces, the Hydropuls test stand simulates the aerodynamic loads occurring in flight on the rudder actuators. This makes it possible to test the behaviour of the system in critical situations under realistic conditions.

hydraulic test cylinders special:

- Very high response characteristics

- Reliability

- Stick-slip-free movements

- Very high positioning and repeat accuracy

neu.jpg?m=1689949330)

Test stand technology

Requirements for the hydropulse test stand

- Complete solution as a closed testing system

- External setpoint specifications from the customer

- Hydraulic actuator including sensor technology and control

- Engineering and software from Hänchen

- Coupling hardware interfaces of external controllers with electronics from Hänchen

Hydraulic test cylinder used as test actuator

- Dimensions 54 / 40 / 180

- Suitable for fluid Skydrol

- Mounting and accessories: spherical rod eye, rod flange, protection tube, position transducer, force transducer, mounting plate, diaphragm accumulator, control valves, intermediate plate, flushing plate

- Sensor technology: position transducer, force transducer

- Seal combination Servofloat®

Ironbird test environment - actuator test stand and cockpit simulation

Interaction and Integration

This means that not only are the individual systems tested, but also their interaction and the integration of the new components into the system, right up to the investigation of the influence of new system solutions on the flight characteristics. Dipl.-Ing. Holger Spangenberg, who is responsible for the Ironbird at the DLR, calls this the "system of systems". A continuous overall system must be in place, from the control input to the actuator deflection. This allows subsystems to be examined more closely and solutions in the area of reconfiguration of flight control systems to be developed. Interactions of the aircraft systems are taken into account with the aim of increasing the safety of aircraft, even under extreme conditions. The early consideration of system interactions is particularly necessary for complex systems such as flight control, as otherwise possible negative influences of various systems are only recognised late and a large part of the development has to be repeated. "The special thing about our Ironbird is that a simulation of the entire flight control chain with a combination of cockpit simulation and actuator test stand can be achieved for a holistic evaluation of flight control systems, even by test pilots," emphasises Spangenberg.

Testing options of the test stand

A test stand for many tasks

Modern test stand technology is able to offer a test environment for a variety of research tasks: New subsystems such as actuators like the Hydropuls cylinders, sensors or computer systems can be integrated into the test stand. With their help, new algorithms for control or condition monitoring and forecasting are developed in order to then test their function - even under various fault conditions. Furthermore, the exploration of new data bus systems such as "fly-by-light" or "wireless flight control" is possible. Another area covered by the Ironbird is the exploration of new flight control concepts for the entire flight control system. The influence of and interaction with subsystems such as sensors, actuators and computers can be investigated.

Condition monitoring

For the exploration of condition monitoring methods for condition monitoring and prognosis of electromechanical or electro-hydraulic flight control actuators, the developed methods are to be investigated and evaluated under the most realistic conditions possible. Here, the Hänchen test actuator are used as hydraulic test cylinders to precisely simulate the aerodynamic loads that act on the rudders in flight. The setpoint values for the control of the hydraulic test cylinder are provided by a flight mechanical simulation. The test system continuously calculates new setpoint values depending on various parameters such as flight speed, altitude and deflection of the rudder and transfers these to the control of the cylinders for simulation of the aerodynamic loads.

Maximum flexibility: Linear drive system Ratio-Drive® made by Hänchen

Hänchen test stand construction supplies the entire linear drive system for two elevators, one aileron and one rudder. The complete Ratio-Drive® system forms a closed system that receives external setpoint specifications. The hydraulic test cylinder test stand works with pressure transducers integrated by Hänchen. This means that the complete actuator, including sensor technology and control as well as software, was realised by Hänchen as a complete solution, including engineering. The company had the task of meeting the requirements for the hydraulic cylinders with regard to the dynamic parameters, the maximum forces that must act on the system, the accuracy of the sensors and the framework conditions of the existing hydraulic system - i.e. fluid, maximum pressure flow and maximum pressure range. This means maximum flexibility, also with regard to the external setpoint specifications. In addition, interfaces had to be solved in terms of hardware: In order to bridge the control system from Hänchen, for example, in order to implement your own control concepts quickly and flexibly with a Rapid Control Prototyping System, it was necessary to couple external controllers with electronics from Hänchen. As there are hardly any lateral forces during the tests, DLR uses test actuator in Servofloat® quality for its test stand.

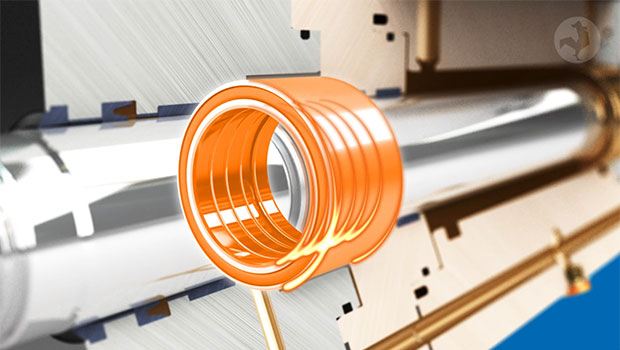

The Servofloat® floating gap seal

Hänchen recommended these test actuator for test stand construction, as the patented floating gap seal is the first choice, especially for applications with limited lateral forces with maximum dynamics and quality. The hydraulic cylinders in Servofloat®-quality are practically friction-free. With extremely slow and very fast movements, they offer non-contact pressure reduction to the outside, low leakage, highest positioning and repeat accuracy and are stick-slip-free.

Equipment test actuator

These seal combinations work according to the following principle: When the system starts, a hydrodynamic oil flow is built up in the cylinder chambers in the floating gap seal, so that the floating gap seal moves metallically without contact in a "floating" and self-centring manner radially around the piston rod: The floating gap seal has a cylindrical shape with a defined clearance to the rod and lies eccentrically in a random position in the installed state. The applied pressure deforms a steel bushing into a pressure-dependent, non-contact sealing gap of a few 1/100 mm. However, this process only works with a production accuracy in the range of a few μm, as otherwise the leakage would lead to high hydraulic losses. Leaking oil is returned pressureless to the fluid circuit via a collecting port. The absence of a touching, pressurised seal minimises static and sliding friction in the hydraulic cylinder. Because no hydrodynamic lubricating film is necessary due to the relative movement of the sliding partners, stick-slip-free movement can also take place in the range of the smallest amplitudes and speeds. The floating gap seal only has a pressure-reducing function with minimal leakage. For this reason, the piston rod of the Hydropuls cylinder is guided by means of friction-optimised wear rings. Nevertheless, a test actuator with a floating gap seal can also absorb certain lateral forces.

In addition, this series has anti-seizure properties due to the bronze-coated piston and bearing surfaces, which additionally increase operational reliability. Another compelling argument for test actuator with floating gap seal is undoubtedly the price. This series only differs from test actuator with hydrostatically mounted piston rod guide in terms of its somewhat higher sensitivity to side loads, but offers a significant price advantage. Learn more about Hänchen hydraulic test cylinders as test actuator.

Concept and performance must be right

According to Spangenberg, the experts at DLR decided to use Hänchen cylinders because of "the good concept and the price-performance ratio of Hänchen's test stand technology. The quasi-hydrostatic behaviour with the same control quality and at a very favourable price ultimately convinced us." The recommendation of a colleague from Airbus, who has been working successfully with Hänchen for years, also played a role. Together with Hänchen, DLR developed the requirements for the system, with helpful tips from the hydraulic experts from Ostfildern being incorporated time and again. A current project is the investigation of new control concepts for dynamic load simulation. Once the control parameters and the concept have been finalised, DLR will incorporate the control structure into the mapping system. "Because simply entering parameters is, of course, more convenient than working with external controllers," explains Spangenberg. This makes Hänchen a manufacturer, service provider and system integrator in one for DLR.

© Hänchen 2009

Why Hänchen as a test stand manufacturer?

Our competence as a manufacturer of test stands and test machines

Our internal product development and research for the development of test stands, test fields and complex test machines laid the foundation for modern test stand construction. Our high quality standards for our own products gave this development a massive boost. Today, Hänchen has developed into a reliable partner for individual test stands and test machines. Every EoL test stand is custom-made to customer specifications. Hänchen test stands are Ratio-Drive® projects, i.e. individually developed special machines with a consistent concept. You as the customer have a central contact person for every project. In this way, individual and energy-efficient test fields and complex test machines can be seamlessly integrated into your own systems through customer-defined interfaces.

Complex in-house and customer projects make Hänchen a reliable quality provider of complete test machines today. This reflects our many years of competence development - starting with cylinder construction, expanded to include electronic components and complete drive systems. Hänchen now offers its customers entire machines, including the drive axis, frame and machine elements.

- More than half a century of hydraulic and seal competence

- Extensive experience in special machine construction of hydraulic and electrical special machines

- Experience in the systematised individual construction of industrial machines and retrofits

- Development of proprietary modular software, including graphical interface for control and regulation as well as communication at process level

- Planning and implementation of test machines and test stands

- Comprehensive safety concepts up to PLe in accordance with the Machinery Directive, CE conformity, safety software