Sealing systems, guiding elements

Individual quantities and small series

- Sealing technology is one of our core competencies

- Experience in precise guiding systems

- Large component diameters, up to 200 mm

- Made in Germany

Sealing technology and guiding technology

Sealing systems

- Pressures up to 2,000 bar

- Temperatures from -40°C to 200°C

- Fluids between moving or static parts

- Mineral oils, synthetic, biodegradable or very special fluids

Guiding elements

-

Cast iron or non-ferrous metal

-

Bronze or synthetic layer inseparably connected to the component

-

Wear rings or bearing bushes

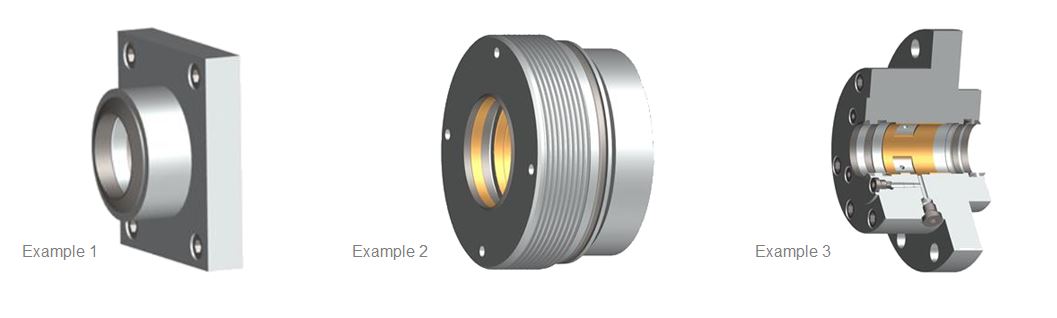

Examples

Typically Hänchen: We are at home in sealing and guiding technology.

From conventional sealing technology to hydrostatic bearing, we are happy to advise you. Component diameters from 12 mm to 200 mm.

- Example 1: Plain bearing flange

-

Flanges are fixed to the machine with screws in order to absorb the forces from rods or shafts.

We develop bearing flanges with precise guiding systems as plain bearings, for example with the special synthetic coating Servoslide®. This coating, firmly integrated into the cover, can be used up to a working temperature of 80°C. The sliding surfaces of the synthetic guide have a vibration-damping effect, avoid edge pressure and ensure largely stick-slip-free movements.

- Example 2: Seal and guide bushing

-

Seals and guide bushings are used in machines where rods or shafts are guided out of a pressurised area.

Suitable seals can withstand pressures up to 300 bar and more, retaining various fluids inside the machine area.

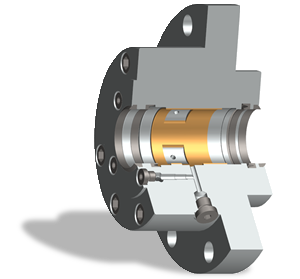

To provide a perfect bearing seat for the rod or shaft, plain bearings made of steel with a high-precision bronze guide are used. This allows rod and shaft lead-throughs to be implemented for temperatures up to 200°C. - Example 3: Hydrostatic bearing

-

The hydrostatic bearing is a non-contact guiding system in which the rod or shaft “floats” on an oil film. This allows linear or rotary bearings with the lowest friction forces and very high bending load to be achieved at the same time.

The pressure supply to the bearing pockets of the hydrostatic bearing is provided by actively applying pressure to the bearing pockets located on the circumference.

We adapt the corresponding rod or shaft to your requirements.