Servohydraulic test actuator

Hydraulic test cylinder for testing

The testing sector is versatile and demanding. The selection of the right components for hydraulic test stands is decisive for the optimal operation of a test machine.

The hydraulic test cylinders are used, for example, to test the functional reliability of systems, components or products, for structural tests of aircraft, cooling compressors, exhaust systems of automobiles or for the simulation of loads and movements, such as driving profiles and flight sequences.

Hänchen has one of the largest test actuator programs on the market and also acts as a manufacturer of other components for test stand construction in a wide variety of industries. In addition, we offer the implementation of complete, individual test machines.

Servohydraulic test actuators

Hydraulic actuators for test applications and test systems

The testing sector is versatile and demanding. The selection of the right components for hydraulic test stands is decisive for the optimal operation of a test machine.

The hydraulic test actuators are used, for example, for testing the functional reliability of systems, components or products, for structural tests of aircraft, cooling compressors, exhaust systems of automobiles or for simulating loads and movements, such as driving profiles and flight sequences.

Hänchen has one of the largest hydraulic test actuator programmes on the market and also acts as a manufacturer of other components for test stand construction in a wide variety of industries.

- Short changeover times

- Adaptable working areas to reduce costs

- Compact construction

- Efficient for changing test series

- High stability and rigidity

- High speeds and high lateral forces

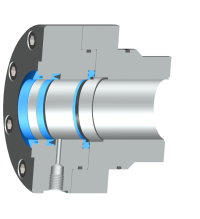

Hydraulic test actuator of the 320 series

Test hydraulic actuators with special features

For every frequency range and high lateral forces

The test actuators impress with their stability and high inherent stiffness. They are suitable for high speeds and can reliably absorb high lateral forces.

Modular system for efficient application change

Mounting parts and accessories such as spherical rod eyes, integrated position transducers, force transducers, mounting plates, accumulators or control valves fit on cylinders of different forces and do not have to be procured several times in a test field.

Operation without leak oil pump

Thanks to the perfectly thought-out seal and guiding system, leak oil pumps are not necessary for Hänchen cylinders.

Hänchen cylinders of the 320 series for test applications are equipped with high-quality bronze coatings for optimum anti-seizure properties. In contrast to other test actuator manufacturers and the earlier Hydropuls cylinders PL and PLF from Schenck.Protection against unforeseen movements

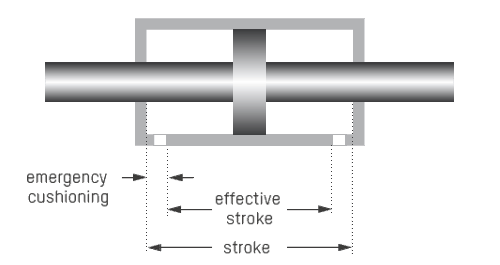

The emergency cushioning serves to protect the cylinder and test object and is included as standard in the stroke. The effective stroke is between the two emergency cushionings.

Bore adjustable to the millimetre

The working areas of the test actuators can be individually designed to meet the respective requirements. This saves on acquisition and operating costs for the required peripherals and achieves high energy efficiency, e.g. in terms of drive and cooling capacity.

Hänchen test hydraulic actuator series

Just right. Really good.

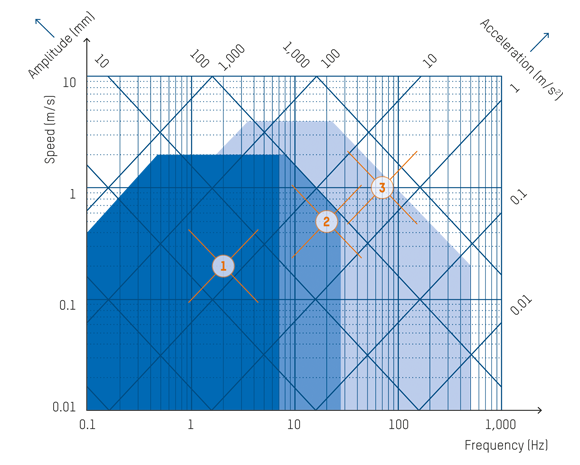

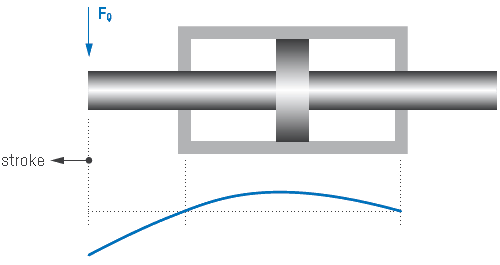

Which cylinder type is the right one for your requirement? The performance chart is used for orientation and describes the dynamic movement of a hydraulic drive during a sinusoidal oscillation. The performance classes of the different cylinder types define the possible applications.

Servo hydraulic actuators of series 120 and 300: slim test actuators for simple testing tasks in typical Hänchen quality - high, honed surface quality, geometric accuracy of the components and matched sealing elements - these servo hydraulic cylinders meet the highest technical requirements, for safe and reliably controlled drives.

Use our HÄKO product configurator for assistance in the design and calculation of your Hydropuls test actuator.

| Examples in the performance chart |

|||

Single-rod |

Double-rod |

series Double-rod |

|

| Frequency (Hz) | 2 | 20 | 70 |

| Amplitude (mm) | 16 | 4 | 2,3 |

| Speed (m/s) | 0,2 | 0,5 | 1 |

| acceleration (m/s2) | 3 | 63 | 440 |

Limit values in the performance chart without considering on-site restrictions such as port size, sealing system, guiding system or control valve.

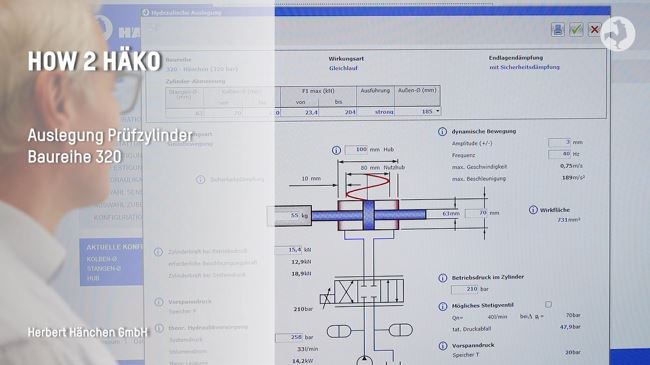

Calculation of the test actuator

Sinusoidal design in HäKo

Using our HäKo product configurator, you can design test actuators as well as round or servo hydraulic actuator (double-rod) using a sinusoidal calculation diagram.

The video explains in detail how to use the tool for designing the sine movement.

Calculation of the test actuator

Sinusoidal design in HäKo

Using our HäKo product configurator, you can design test actuators as well as round or servo hydraulic actuator (double-rod) using a sinusoidal calculation diagram.

The video explains in detail how to use the tool for designing the sine movement.

The video explains the sinusoidal movement design tool in detail.

Subtitles in your language:

You can activate the subtitles by pressing the "c" button or in the video at the bottom right. You can have them translated into your language via the settings (gear icon).

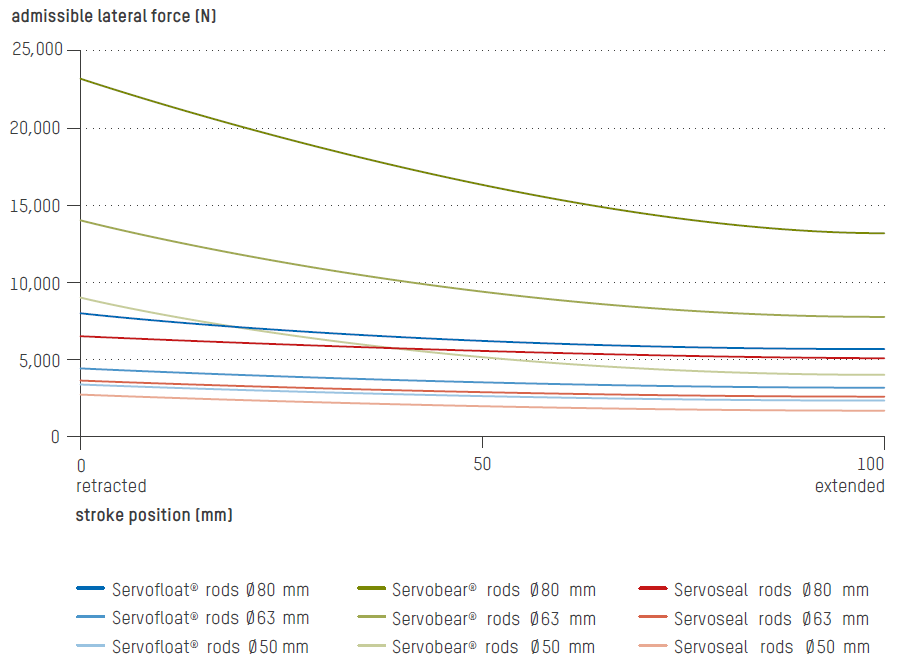

Lateral force design

Lateral forces on the piston rod for test actuators of the 320 series

The magnitude of the permissible lateral forces is mainly determined by the rod diameter, the guiding system and the cylinder stroke. This results in different values depending on the stroke position. The permissible lateral force in the retracted end position is always greater than in the extended position. For test actuators with longer strokes, the choice of sealing and guiding systems is of minor importance with regard to lateral force absorption.

A quick overview can be found in the table below Technical data depending on the nominal force

The exact lateral force curves for each dimension can be found in our Hänchen Configurator HÄKO under >> Test actuator >> Equipment

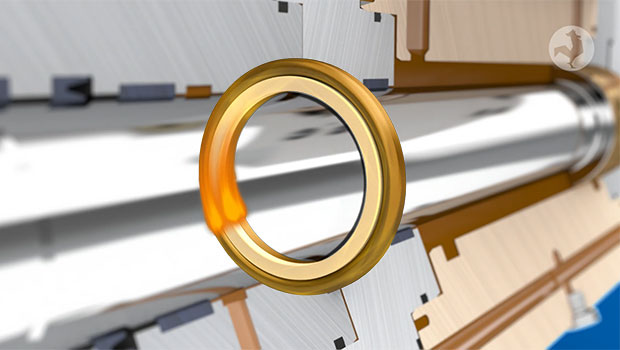

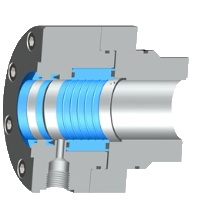

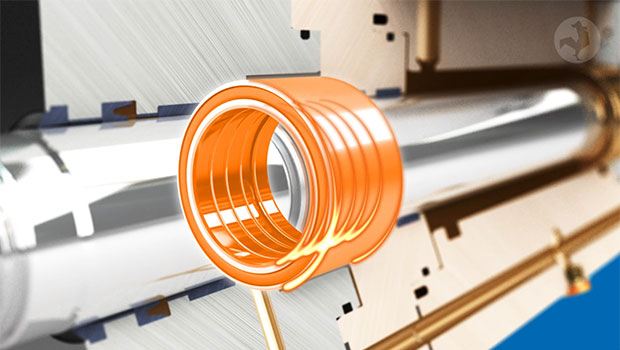

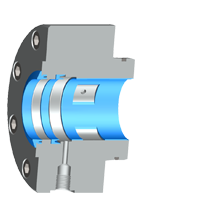

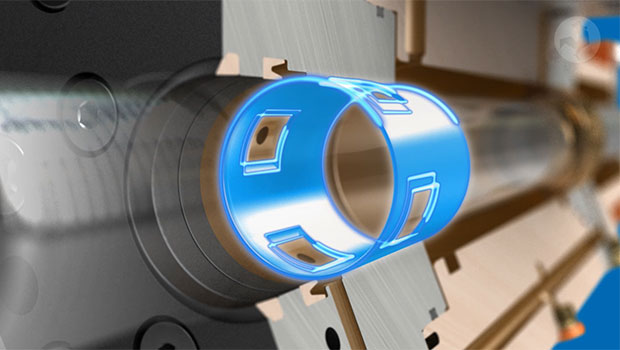

Cover design for servo hydraulic test actuators

Sealing and guiding system in the cover

In a dynamic test environment, free-moving hydraulic cylinders with low stick-slip are required. Hänchen offers three versions of test actuators that are particularly low-friction. High manufacturing accuracy with little guide clearance guarantees wear-free use and thus a long service life.

| Guiding system cover | PTFE wear rings = contacting guide elements |

| Sealing system cover |

Servoseal®, lip seal, wiper ring |

| Operating limits |

Speed: 3 m/s Temperature: 80 °C Friction: pressure-independent |

| Guiding system cover | PTFE wear rings = contacting guide elements |

| Sealing system cover |

floating gap seal, functional oil seal, wiper ring |

| Operating limits |

Speed: 4 m/s |

| Guiding system cover | PTFE wear rings = contacting guide elements |

| Sealing system cover |

Functional oil seal, wiper ring |

| Operating limits |

Speed: 4 m/s |

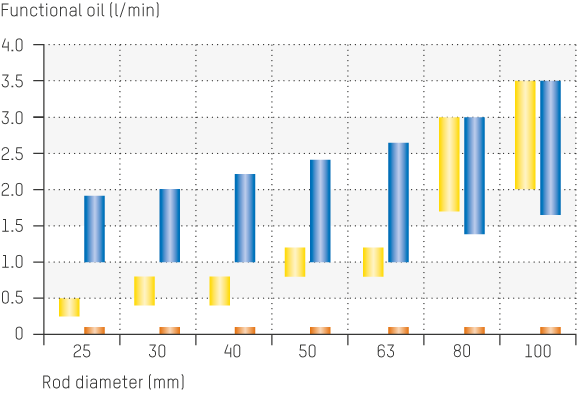

Hydraulic design

Flow rate in test cylinders

When designing the required flow rate, the gap seals used in the test actuator must be taken into account. In the cover, this refers to the functional oil flow required for the Servofloat® and Servobear® designs. In contrast, leakage occurs on the piston in the "fitted piston" version. This additionally required oil must be added to the flow rate required for the operation of the hydraulic test cylinder.

Functional oil flow in covers

For very friction-sensitive applications with small amplitudes, the sealing system Servoseal® or throttle gap seals are used on the cover or piston. Servoseal® produces only a very low leakage, which is barely measurable during operation. This allows very high hydraulic efficiencies to be achieved.

![]() Servocop®, Servoseal®

Servocop®, Servoseal®![]() Servofloat®

Servofloat®![]() Servobear®

Servobear®

Reference values apply to one cover at 210 bar chamber pressure (working pressure), fluid ISO VG 46 at 55 °C.

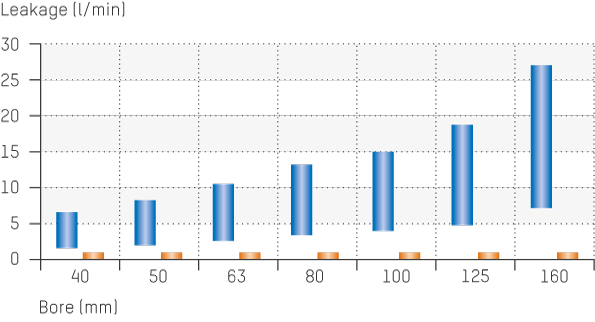

Leak oil diagram on the piston

Gap seals work with a functional oil flow, which is discharged pressureless into the tank via the leak oil port. It must not be sucked off.

![]() Rectangular compact seal, Servoseal®

Rectangular compact seal, Servoseal®![]() Gap seal

Gap seal

Reference values apply for 210 bar differential pressure at the piston,

fluid ISO VG 46 at 55 °C.

Technical data hydraulic actuator

Test actuator of series 320

According to the rod diameter

Type of effect: double-rod cylinder | Sealing systems: Servoseal®, Servofloat®, functional oil seal (Servobear®) | Speeds: up to 4 m/s

| Rod Ø (mm) |

Type |

Bore (mm) |

Force (kN) 210 bar |

Force (kN) 320 bar |

Stroke (mm) |

| 25 | strong | 28 – 45 | 2.6 – 23.1 | 4.0 – 35.2 | 50 – 170 |

| 30 | strong | 34 – 55 | 4.2 – 35.0 | 6.4 – 53.4 | 50 – 220 |

| 40 | strong | 45 – 70 | 7.0 – 54.4 | 10.7 – 82.9 | 50 – 270 |

| 50 | strong | 56 – 80 | 10.5 – 64.3 | 16.0 – 98.0 | 50 – 450 |

| 63 | strong | 70 – 110 | 15.4 – 134 | 23.4 – 204 | 50 – 450 |

| 80 | slim | 90 – 120 | 28.0 – 132 | 42.7 – 201 | 50 – 450 |

| 80 | strong | 90 – 150 | 28.0 – 266 | 42.7 – 404 | 50 – 450 |

| 100 | slim | 110 – 150 | 34.6 – 206 | 52.8 – 314 | 50 – 450 |

| 100 | strong | 110 – 175 | 34.6 – 340 | 52.8 – 518 | 50 – 450 |

| 125 | slim | 140 – 175 | 65.6 – 247 | 100 – 377 | 50 – 450 |

| 125 | strong | 140 – 200 | 65.6 – 402 | 100 – 613 | 50 – 450 |

| 160 | slim | 180 – 220 | 112 – 376 | 171 – 573 | 50 – 450 |

| 160 | strong | 200 – 260 | 238 – 693 | 362 – 1,056 | 50 – 450 |

| 200 | slim | 240 – 280 | 290 – 633 | 442 – 965 | 50 – 450 |

| 200 | strong | 250 – 320 | 371 – 1,029 | 566 – 1,568 | 50 – 350 |

strong: massive construction (e.g. vertical installation)

slim: light construction (e.g. horizontal installation with spherical rod eyes)

According to the nominal force

| Nominal force (kN) |

Design |

Rod Ø (mm) |

Bore (mm) |

Force (kN) 210 bar |

Lateral force when extended (kN) |

||||||||||||

| Stroke 100** | Stroke 250** | |||||||||||||||||

| Servoseal® | Servofloat® | Servobear® | |||||||||||||||

| 4 | light rod normal rod |

25 30 |

30 34 |

4,5 4,2 |

0,31 0,51 |

0,27 0,44 |

0,51 1,0 |

||||||||||

| 6,3 | light rod normal rod |

30 40 |

36 45 |

6,5 7,0 |

0,51 1,6 |

| |

0,57 |

0,44 1,5 |

| |

0,54 |

1.0 2.5 |

| |

0,67 |

||||

| 10 | light rod normal rod* |

30 40 |

39 47 |

10,2 10,0 |

0,51 1,6 |

| |

0,57 |

0,44 1,5 |

| |

0,54 |

1.0 2.5 |

| |

0,67 |

||||

| 16 | light rod normal rod* reinforced rod |

30 40 50 |

44 51 59 |

17,1 16,5 16,2 |

0.51 1.6 2.8 |

| | |

0,57 1,6 |

0.44 1.5 2.4 |

| | |

0,54 1,2 |

1.0 2.5 4.6 |

| | |

0,67 1,2 |

||||

| 25 | light rod* normal rod reinforced rod |

40 50 63 |

56 64 74 |

25,3 26,3 24,9 |

1.6 2.8 3.8 |

| | | |

0.57 1.6 3.2 |

1.5 2.4 3.6 |

| | | |

0.54 1.2 2.9 |

2.5 4.6 7.8 |

| | | |

0.67 1.2 2.3 |

||||

| 40 | light rod normal rod* reinforced rod |

40 50 63 |

64 70 80 |

41,2 39,6 40,1 |

1.6 2.8 3.8 |

| | | |

0.57 1.6 3.2 |

1.5 2.4 3.6 |

| | | |

0.54 1.2 2.9 |

2.5 4.6 7.8 |

| | | |

0.67 1.2 2.3 |

||||

| 63 | light rod* normal rod reinforced rod |

50 63 80 |

80 88 101 |

64,3 62,3 62,7 |

2.8 3.8 6.7 |

| | | |

1.6 3.2 4.5 |

2.4 3.6 6.4 |

| | | |

1.2 2.9 5.1 |

4.6 7.8 13.3 |

| | | |

1.2 2.3 4.4 |

||||

| 100 | light rod normal rod* reinforced rod |

63 80 100 |

100 112 127 |

99,5 101,3 101,1 |

3.8 6.7 11.1 |

| | | |

3.2 4.5 9.7 |

3.6 6.4 10.3 |

| | | |

2.9 5.1 8.7 |

7.8 13.3 24.9 |

| | | |

2.3 4.4 9.7 |

||||

| 160 | light rod* normal rod reinforced rod |

80 100 125 |

127 140 160 |

160,5 158,3 164,5 |

6.7 11.0 16.2 |

| | | |

4.5 9.7 15.9 |

6.4 10.3 15.1 |

| | | |

5.1 8.7 14.6 |

13.3 24.9 49.5 |

| | | |

4.4 9.7 23.9 |

||||

| 250 | light rod normal rod* reinforced rod |

100 125 160 |

160 175 202 |

257,3 247,4 250,8 |

11.0 16.2 24.7 |

| | | |

9.7 15.9 24.0 |

10.3 15.1 22.1 |

| | | |

8.7 14.9 22.7 |

24.9 49.5 81.6 |

| | | |

9.7 23.9 42.2 |

||||

| 400 | light rod* normal rod reinforced rod |

125 160 200 |

200 225 225 |

402,0 412,7 412,7 |

16.2 24.7 31.7 |

| | | |

15.9 24.0 30.6 |

15.1 22.1 |

| | | |

14.6 22.7 |

49.5 81.6 99.1 |

| | | |

23.9 42.2 58.4 |

||||

| 630 | normal rod* reinforced rod |

160 200 |

225 280 |

650,3 633,3 |

24.7 31.7 |

| | |

24.0 30.6 |

22,1 | | | |

22,7 | 81.6 99.1 |

| | |

42.4 58.4 |

||||

| 1.000 | normal rod* | 200 | 320 | 1.029,2 | 31,7 | | | 30,6 | | | 99,1 | | | 58,4 | ||||||

The assignment of the piston to the nominal force is for orientation purposes. For optimised design taking into account hydraulics, dynamics or weight, please use the calculation in our HÄKO product configurator.

* Reference to market-standard dimensions such as the Schenck actuators.

** Mechanical guiding systems in Servoseal® and Servofloat® are limited by the permissible surface pressure, but can absorb very high lateral forces and deflections with long strokes. Hydrostatic bearings (Servobear®) are characterised by a very high bearing and lateral force capacity, especially with short strokes.