Individual designs for custom cylinders

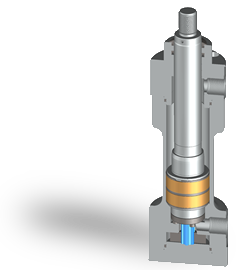

Screw-in cylinders

Hydraulic cylinders are mechanically attached and then hydraulically connected with hoses or pipes. A space-saving alternative are screw-in cylinders, which are installed in stepped bores with a stepped cylinder housing. This cylinder, which can be used in a block, is usually integrated into a machine and protected from external influences. The advantages:

- Small installation volume

- Simple installation without screwed fittings