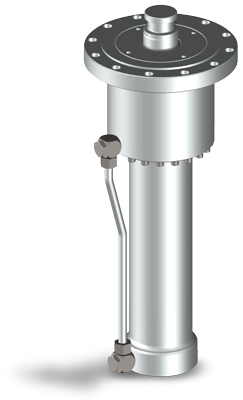

Rapid traverse cylinder with power stroke

Press cylinder, hydraulic cylinder with rapid traverse function

Rapid traverse cylinders are used when a very high force is required over a short stroke range when starting up the hydraulic cylinder. For the remaining travel of the hydraulic cylinder, a higher travel speed is required, but a smaller force is sufficient for this.

The advantage of these rapid traverse cylinders is that a smaller power unit can be used, as the power for the increased force and the fast travel range is not required at the same time. In addition, the rapid traverse function can shorten the working cycles of the machine.

- One hydraulic cylinder - two force curves

- Energy-saving: less power required for rapid traverse

- Increased productivity through higher work cycles

Applications for rapid traverse cylinders

Foundry, die casting, press engineering

Such dual-force cylinders with rapid traverse function are used, among other things, in foundries or in press construction, hence the name “press cylinder with integrated rapid traverse”.

Foundry and die casting

To open the casting mold, an increased force is required to loosen the mold from the components - to "tear it open" - so that the mold can be opened. As soon as the mold has been released, only a little force is required, but the rapid traverse cylinder should return the remaining opening stroke as quickly as possible.

Press engineering

A high force is required for the pressing process. This high pressing force is usually applied shortly before the end position of the hydraulic cylinder. During the rest of the movement, the press cylinder runs with a significantly lower load; among other things, it is only necessary to keep the space free for loading.

Enter your postcode to be put in direct contact with your relevant contact person.

Function

Rapid traverse cylinder in retraction direction with power stroke at the start of the stroke

In the case of the rapid traverse cylinder, which applies the high force by pulling, the surface of the additional piston (A3) is automatically pressurised (p2) during the return stroke. As long as the additional piston is in contact with the piston surface (A2), the piston rod retracts with high force until the additional piston hits the end stop. From this moment on, the piston rod (A2) can retraction faster to the desired position, as its working area is smaller. The additional piston can either be actively pressurised via port p3 or passively moved by the piston rod via air filter and leakage oil line.

| Formula symbol | |

| A1 / p1 | Extension stroke |

| A2 | Rapid traverse |

| A3 / p2 | Power stroke |

Function

Rapid traverse cylinder extending with high force at the end of the stroke

The piston rod of the rapid traverse cylinder, which applies the high force to pressure, is hollow bored. This contains an additional rod with a small working area (A3). The small rapid traverse area (A3) is pressurised (p3) for rapid extend. During this rapid traverse, the fluid required to fill the large chamber for the force passage is provided by means of a pre-fill valve or with low pressure (p1). The power gear with the large surface of the piston rod (A1) can be hydraulically engaged at any time and at any position.

| Formula symbol | |

| A1 / p1 | Power stroke - Suction / pressure port |

| A3 / p3 | Rapid traverse |

| A2 / p2 | Return stroke |