Rods, shafts, axles

Individual quantities and small series

- Material procurement

- Complete machining

- Surface treatment

- Tolerances up to h6

- ISO 9001:2008 certification

- Decades of experience

- Technical consulting

- Acceptances and tests

Surface finish.

Rods, shafts, axles.

We produce individual pieces or small series for you on our machining centers up to Ø 600 mm and a length of up to 400 mm. Machining up to Ø 200 mm and a length of up to 3,500 mm is possible on our lathes.

- Material quality

High-quality steel mill materials such as 20MnV6, 42CrMo4V, 16MnCr5, stainless steels such as 1.4571 or 1.4462, but also aluminum alloys or non-ferrous metals form the starting material for production.

- Design and engineering drawing

- We would be happy to take over the development and design for your individual machine element or manufacture according to your model. We use modern methods such as FEM calculations and CAD/CAM.

- Coating

Anodised aluminum, hardened steel, hard-chrome plated or with a nickel layer – as required by your application. Bronze and synthetic layers can be applied internally and externally as sliding surfaces.

Design.

We make the rod functional.

Be it as a precision shaft, axle, guide pillar or piston rod. As an integrated beam, guide rod or pressure-resistant distributor for supplying fluids under high pressure.

- Precision shaft

Whatever ends you want your shaft or rod to have, we offer you whatever you need: external thread, internal thread, pin, cylindrical or tapered shaft seat, radial bore or feather key groove, with wrench flats, square or hexagon.

- Functional rod

Connecting rods and piston rods with round or rectangular flanges, shafts with disks. One-piece, welded on at the end or in the middle. Trunnions flange with their special geometry are also no problem for us.

- Distributor axle

High-pressure resistant fluid distributors, drilled lengthways and crossways. With pipe threads or tapered threads for direct port connection of the supply line. If required, also with suitable sealing rings for direct installation in your machine housing.

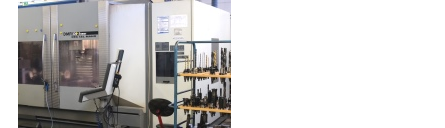

Manufacturing technologies

Machined with state-of-the-art turning, drilling and milling centers. Finely machined by internal and external honeing, finishing and grinding. Solid, as a hollow shaft or with deep-hole drilling – in all common ISO fits. Below you will find our manufacturing technologies; thanks to our good partner network, we can also realize larger dimensions in the turning and milling area.

- Turning

- Up to Ø 200 mm

- Length up to 3,500 mm

- Hone

- Internal Ø 650 mm

- External Ø 400 mm

- Length up to 7,000 mm

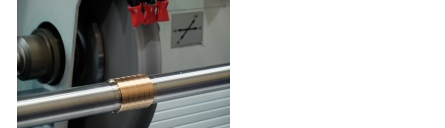

- Grinding

- External cylindrical grinding: Grinding length up to 1,800 mm, Ø 400 mm

- Surface grinding: 600x300x400 mm (LxWxH)

- Material: Steel, bronze, aluminium, ...

- Welding

- Robot-controlled welding Ø up to 500 mm

- Length up to 6,000 mm

- Coating

- Coating steel with synthetic or bronze

- Corrosion protection (phosphating/nickel plating/galvanising/chrome plating/painting)

- Anodising

- Milling

- Up to Ø 600 mm

- Length up to 2,000 mm

Acceptances and tests

- Ultrasonic testing

- Dye penetration testing

- Magnetic particle testing

- Execution of acceptance test certificate 3.1 and 3.2 according to DIN EN 10204

- Further tests on request

Application examples of rods, shafts, axles

|

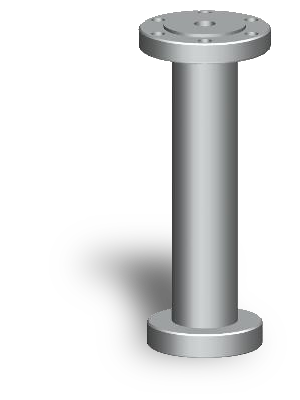

Support shaft for test setup

Manufacturing steps: turning and mounting holes Material: S355, diameter 260 mm or 75 mm and length 350 mm |

|

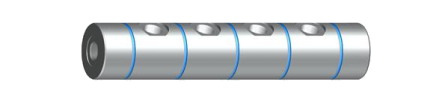

Take-up shaft for textile machine

Manufacturing steps: turning, drilling and honeing Material: 20MnV6 chrome-plated and honed, diameter 25 mm and length 469 mm |

|

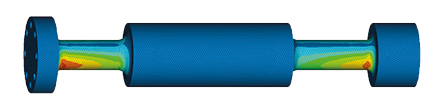

Shaft for yoke test stand

Manufacturing steps: turning and peripheral machining Material: 42CrMo4V, diameter 200 mm and length 1,200 mm |

|

Drive rod

Manufacturing steps: turning and cutting to length Material: 42CrMo4V, different diameters from 150 to 180 mm and length 912 mm |

|

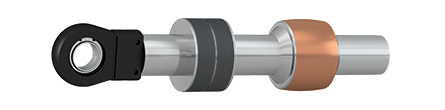

Piston rod for conveyor technology

Manufacturing steps: sawing and turning on both sides Material: Bearing material 20MnV6 chrome-plated and honed, diameter 30 mm and length 655 mm |

|

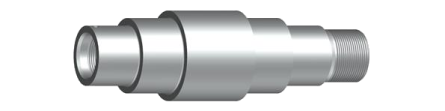

Extension rod for synthetic manufacturing

Manufacturing steps: turning, threading and surface milling on the circumference Material: Grade C 45 K, diameter 32 mm and length 626 mm |

|

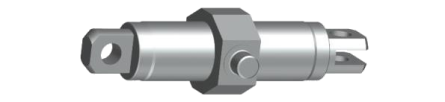

Adapter piece in special machine construction

Manufacturing steps: turning, drilling and milling Material: 42CrMo4V chrome-plated, diameter 36 mm and length 80 mm |