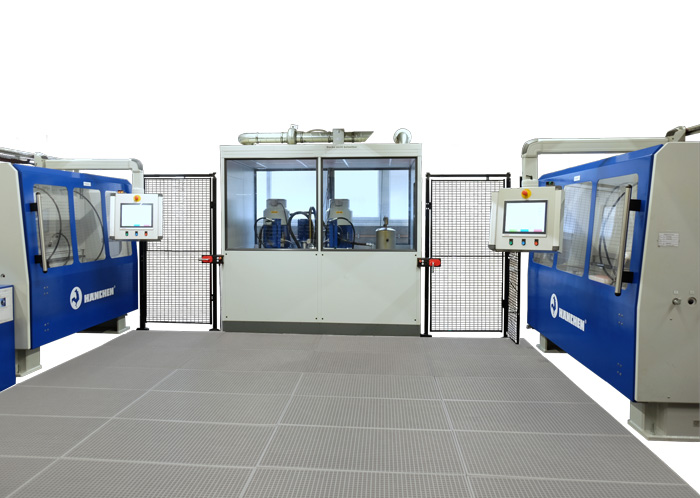

End of Line test stand for hydraulic products

Hydraulic test machine Ratio-Drive®

The end-of-line test stand enables comprehensive functional testing at the end of the manufacturing process. This hydraulic test machine was developed and realised for the final inspection of hydraulic cylinders, pressure intensifiers and other hydraulic products.

EoL test stands for increased process reliability and reduction of production costs

Volker Kaiser, team leader of quality assurance at Hänchen: "Previously, it was necessary to know every work step in detail, because in the past, employees manually controlled the testing process. The test pressure was set manually, which was associated with certain deviations." With the automated end-of-line test stand, we achieve greater process reliability and simultaneously reduce the workload.

- Complete turnkey EoL test stands

- Customised implementation

- Safety concepts up to PLe

- Users and developers of test machines

Test stand structure

Technical data EoL test stand

- Maximum, precisely configurable hydraulic pressure up to 500 bar, realised by Hänchen pressure intensifier

- Maximum adjustable flow rate up to 30 l/min

- Oil used: HLPD46

Hydraulics

- Radial piston pumps 30 kW

- Monitoring of oil temperature and level

- Pressure monitoring

Test stand electronics

- Touch displays

- Frequency converters for motor control

- Beckhoff control system

Test stand software & safety technology

- Hänchen software development

- Fully automatically monitored test stand doors

- Safety concept according to PLe

End of Line test stand for high-quality hydraulic products

Optimising the manufacturing process

Hänchen products stand for the highest quality, which is ensured by EoL test stands. For Hänchen, quality begins with particularly high consulting expertise for optimal product configuration, for example for hydraulic cylinders. A crucial quality factor of Hänchen products is the careful design. Equally decisive are the choice of the right materials and our extensive experience in the selection of suitable bought-in components. Hänchen hydraulic cylinders go through many production steps during manufacturing. Each one guarantees the high precision and quality of Hänchen products such as test actuators and others. To ensure the quality of Hänchen products and components, they are 100% tested on the end-of-line test stand after assembly. The test result of each product is carefully documented and can be accessed at any time.

Fully automatic and reproducible functional testing

With the new software-controlled test machine, we have fully automated the End of Line testing process. This fully automatic functional test is initiated by a barcode on the test object. The Hänchen test software accesses data from the ERP system. This means that the correct parameters are automatically created in the test stand, such as test pressure and traversing speed.

At the end of the functional test, the test data is recorded in a test certificate and archived accordingly in the document management system (DMS). The test certificate can be called up at any time and passed on to the customer if required. Each testing process is thus comparable and reproducible. The holding fixture, which is specially adapted to the Hänchen-typical test objects, enables safe handling of the test objects. Components such as hydraulic cylinders with an outside diameter of 25 – 500 mm can be safely fixed. The length of the EoL test stand was designed for a maximum component length of 2.50 m. Larger components can also be connected and tested outside the test cell.

Katharina Preiß - Jörg Beyer, mediaword

© Hänchen 2017

We often extend this test stand for our customers to include the "Mechanical load test" function.

Why choose test fields, test machines and test stands from the manufacturer Hänchen?

Our competence as a manufacturer of test stands and test machines

The foundation for the development of test stands and complex test machines was laid by Hänchen's internal product development and research. Starting with hydraulic cylinder construction, expanded to include electronic components and complete drive systems, Hänchen also offers its customers complete machines, including drive axes, frames and machine elements. Our high quality standards for our own products gave this development a massive boost. This many years of experience makes Hänchen your reliable partner for individual test stands and test machines today. Each EoL test stand is tailored to you as a customer.

Hänchen test stands are Ratio-Drive® projects, meaning they are individually developed special machines with a consistent concept. For each project, you as the customer have a central point of contact. This allows the individual test stand to be seamlessly integrated into your own systems through customer-defined interfaces.

Use the postcode search to find the responsible contact person directly.

Hänchen Ratio-Drive® - The complete solution for drive systems & test stand construction

- More than half a century of hydraulic and seal competence

- Extensive experience in special machine construction of hydraulic and electrical special machines

- Experience in the systematised individual design of industrial machines and retrofit

- Measurement, control and regulation technology, real-time control, measured value acquisition, sensor technology, fieldbus connection and evaluation

- Development of proprietary modular software, including graphical interface for control and regulation as well as communication at process level

- Planning and implementation of test machines

- Individual test stand construction

- Comprehensive safety concepts up to PLe in accordance with the Machinery Directive, CE conformity, safety software