Servo-hydraulic seat test stand for the automotive industry

Test stand drive with Hänchen test cylinders

Servo hydraulic life-cycle tests are now an industry standard for automotive components and are used far beyond safety-relevant components. The challenge in test stand construction for the automotive industry is to bring together different technologies at the highest level. The testers place particularly high demands on the test actuator and real-time control.

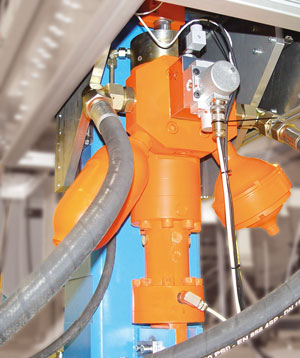

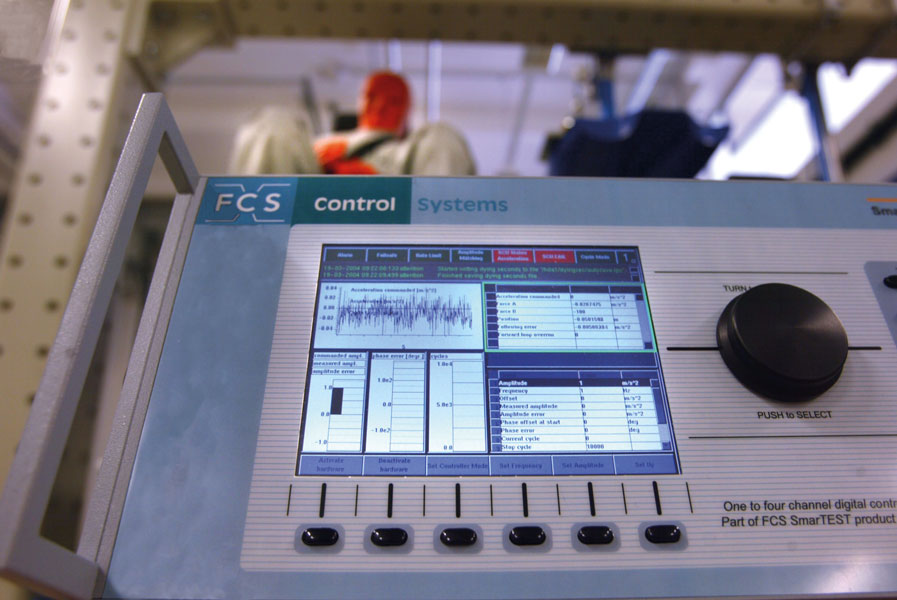

The development service provider IAV GmbH from Gifhorn has put a servo hydraulic seat test stand into operation. The control system is a digital servo controller from FCS Control-Systems. Hänchen Hydraulik supplied the test cylinder for the drive of the test stand.

Hänchen as general contractor for test stand construction

We build individual test stands for you - be it for car seats, aircraft seats or completely different material and function tests. You can find out more on our pages about the special machine construction of complete test machines.

- High quality and reliability of the test actuators

- Stick-slip-free cylinder movements

- Flexible and committed cooperation

- High positioning and repeat accuracy

Dynamic test machine

Technical test stand requirements

- Test force up to 28 kN

- Frequency up to 20 Hz

- Dynamic stroke up to 35 mm

- Speed up to 1.3 m/s

- Acceleration up to 50 m/s2

- Low-friction sealing system

Electronics

- 20 GB hard drive

- Each unit can address up to 4 channels simultaneously

- Larger FCS systems control over 300 channels

- Ergonomic single-button control

- Display in VGA format

- PC keyboard

Benefit from our comprehensive know-how in hydraulic drives and modern test stand technology.

From decades of experience in the engineering of test actuators, we have developed into a general contractor for the construction of complete test stands and test machines. This also includes functional test stands for performing vibration tests and shock tests on end products.

Vibration test stand version for wear testing

Components to be tested in the test stand

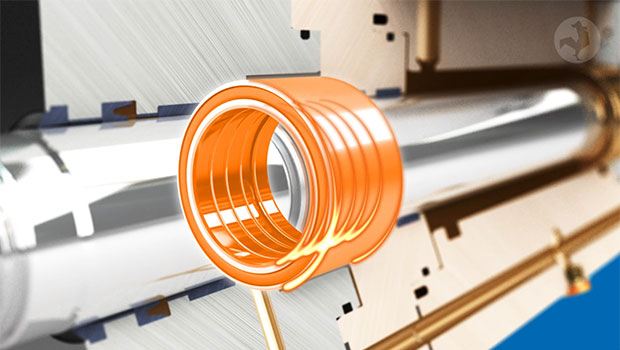

The wear testing of the seats is carried out by a Hänchen test actuator series 320">test actuator from the former series 328 (today series 320) as an actuator. The patented, floating floating gap seal Servofloat® is used in this double-rod cylinder. A steel bushing follows the radial deflection of the piston rod, with a sealing gap of a few 1/100 mm that is practically constant over the entire pressure range. This cylinder series differs from a test actuator with hydrostatically mounted piston rod guide only in its somewhat higher sensitivity to side loads, but offers a cost advantage of around 30%. This is because only the leak oil seals cause a negligible minimum amount of friction. Due to their extremely low friction, test actuators in Servofloat® offer the highest positioning and repeat accuracy, are stick-slip-free and are suitable for extremely slow and fast movements.

The seat test stand operates in standard mode with a test force of up to 28 kN at a frequency of maximum 20 Hz, a dynamic stroke of up to 35 mm, a speed of up to 1.3 m/s and an acceleration of up to 50 m/s². Nevertheless, it still has high safety reserves that ensure optimum operation: The technically permissible maximum speed, for example, is 4 m/s.

Structure of seat test stand

Use of test actuators

When the seat test stand system starts, a hydrodynamic oil flow is built up in the floating gap seal via the cylinder chambers. This allows the floating gap seal to move metallically without contact, 'floating' and self-centering radially around the piston rod. The exiting leak oil is returned to the fluid circuit without pressure via a collecting port. The absence of a touching, pressurised seal minimises static and sliding friction in the test actuator. Because no hydrodynamic lubricating film is necessary due to the relative movement of the sliding partners, stick-slip-free movement can also occur in the range of the smallest amplitudes and speeds. The floating gap seal only has a pressure-reducing function with minimal leakage. Therefore, the piston rod is guided by means of friction-optimised bands. Nevertheless, a test actuator with a floating gap seal can also absorb certain lateral forces. In the specific application, 1.2 kN are permissible, which are absorbed by synthetic guide strips. The test actuator series 328 (now series 320) also has anti-seizure properties due to the piston and bearing surfaces coated with special bronze, which additionally increase operational reliability.

The oil supply to the test stand is of decisive importance for the effectiveness of the floating gap seal. The cleaner the oil, the more reliably the system works. If the particles in the oil are no larger than 3/4 of the smallest gap height, the gap rings will not wear. Hänchen therefore recommends cleanliness class 13/11 according to ISO 4406. In test and testing systems, hydraulic cylinders with the floating gap seal offer a real high-performance cylinder with a significant price advantage compared to cylinders with hydrostatically mounted piston rod guide. Hänchen also offers these high-end test actuators, which can compensate for a maximum of lateral forces. As there is no starting friction, the low stick-slip operation is guaranteed even at the smallest piston speeds. Only the pressureless wiping elemento di guarnizione causes a low residual friction, which is constant over the entire pressure range. This avoids the complex and workplace-polluting extraction of leak oil.

Fulfilling the dynamic requirements of the test stand

Hänchen Ratio-Drive® - The complete solution for drive systems & test stand construction

- More than half a century of hydraulic and seal competence

- Extensive experience in special machine construction of hydraulic and electrical special machines

- Experience in the systematised individual design and realisation of customer projects

- Experience in the systematised individual construction of industrial machines and retrofits

- Measurement, control and regulation technology, real-time control, measured value acquisition, sensor technology, fieldbus connection and evaluation

- Development of proprietary modular software, including graphical interface for control and regulation as well as communication at process level

- Individual test stand construction

- Planning and implementation of test machines

- Comprehensive safety concepts up to PLe in accordance with the Machinery Directive, CE conformity, safety software