Hydrostatic bearing Servobear®

Guiding system cover

The guiding system in the cover Hydrostatic piston rod bearing Servobear® is particularly suitable for highly dynamic movements and oscillations with high dynamic side loads.

With a hydrostatic piston rod guide, the lowest friction forces can be achieved with a very high lateral force load on the piston rod at the same time.

Depending on the series, the sealing materials and the sealing system, this system is suitable for:

| Piston speeds | up to 4 m/s |

| Temperature range | from -30 °C to +100 °C |

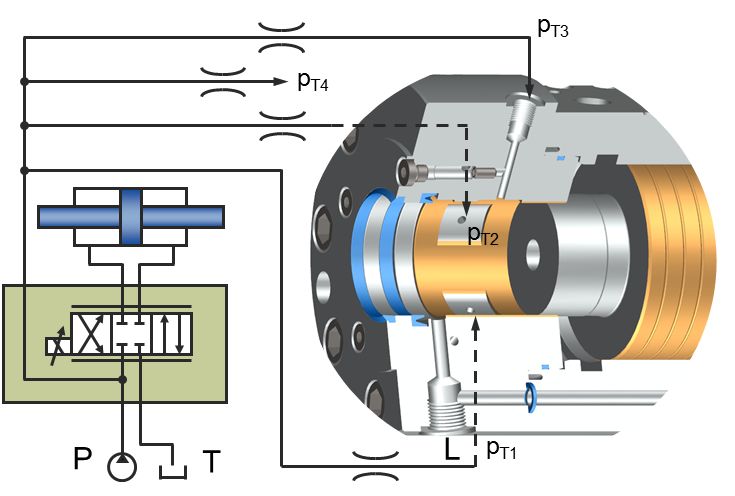

Function

In the hydrostatic bearing, the non-contacting piston rod guide and throttle gap seal are integrated in one component. The rod “floats” on an oil film, which is generated by the bearing pockets incorporated on the circumference. Depending on the rod diameter, 4- or 6-pocket bearings are used.

The contacting (functional oil) sealing system and the wiper ring are not under pressure, resulting in very low residual friction that remains constant over the entire pressure range.

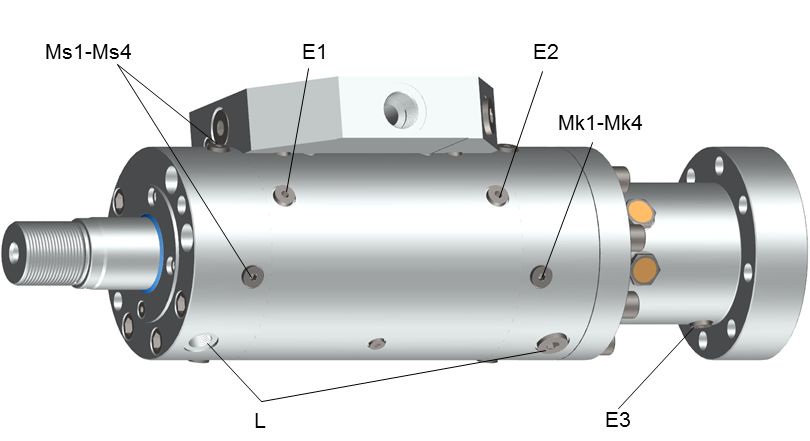

| L | Function port G1/4 or G1/2 |

| E1 | Head side vent G1/4 |

| E2 | Vent cap side G1/4 |

| E3 | Vent protection tube G1/4 (optional) |

| Ms1-Ms4 | Measuring port hydrostatic pocket 1 to 4 head side |

| Ms1-Mk4 | Measuring port hydrostatic pocket 1 to 4 cap side |

The hydrostatic bearing is supplied internally through channels in the cylinder via the system pressure. The supply pressure corresponds to the system pressure upstream of the servo valve, pmin = 140 bar, pmax = 320 bar.

The functional oil flow is returned to the tank pressureless via the functional oil port. It must not be extracted using vacuum.

A preload of the functional oil line up to 5 bar is permissible.

Series 320:

The functional oil ports are internally connected for optional connection.

The amount of functional oil produced depends, among other factors, heavily on the viscosity of the fluid used, the temperature and, in particular, on the pressure conditions prevailing in the cylinder.

The functional oil quantities shown here were determined for a fluid ISO VG 46 at 55°C. However, they should only be used as guide values for the hydraulic design; an exact determination of the functional oil flow can only be carried out on the device itself by means of measurements.

| Functional oil flow Servobear® with hydrostatic piston rod guide |

||

| Rod diameter [mm] |

Functional oil min.* [l/min] |

Functional oil max.* [l/min] |

| 25 | 1,0 | 1,9 |

| 30 | 1,0 | 2,0 |

| 40 | 1,0 | 2,2 |

| 50 | 1,0 | 2,4 |

| 63 | 1,0 | 2,6 |

| 80 | 1,4 | 3,0 |

| 100 | 1,6 | 3,5 |

| 125 | 2,0 | 3,7 |

| 160 | 3,0 | 4,5 |

| 200 | 3,2 | 4,7 |

* The functional oil specifications for Servobear® apply to one chamber at a supply pressure (system pressure) of 280 bar.