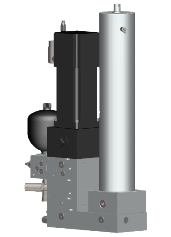

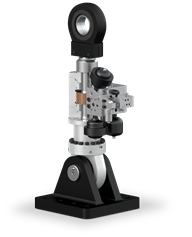

Special machines Ratio-Drive®

In the following, you will find application reports on the use of hydraulic cylinders, clamping units and hydraulic drive concepts for systems and machines. We convince our customers with:

We offer a wide range of hydraulic cylinders, which you can individually configure in our HÄKO configurator. We are also happy to support and advise you personally in your selection. If your requirements are particularly specific, we will adapt our cylinders to your application.

We have been producing hydraulic cylinders since 1952 and are happy to take on even the most demanding tasks. Therefore, we have in-depth expertise in the design and manufacture of high-quality hydraulic cylinders.

Hänchen stands for:

Our products are state-of-the-art, energy-efficient and reliable. We achieve this with our highly competent employees who are specialized in their field.

Hänchen perceives its role as a consultant with integrity and transparency. We are always looking for the best solution in the interest of our customers.

Our machinery is carefully selected and continuously expanded to ensure high production quality. This enables us to achieve durable and robust products.

We design our products for long service life in terms of application and maintenance. With us, you can still get spare parts and support even after years.