Longitudinal slide drive in multi-spindle automatic lathes

Industrial hydraulic cylinders in machine tools

Multi-spindle automatic lathes are a basic requirement for efficient and precise series production in which complex metal bodies are turned. These have been a product focus of the machine construction company Alfred H. Schütte in Cologne since 1915, when it launched the first 4-spindle automatic lathe on the market. In these machines, several cutting tools simultaneously machine the workpiece, which reduces the cycle time to a fraction compared to a simple lathe with successively changing tools.

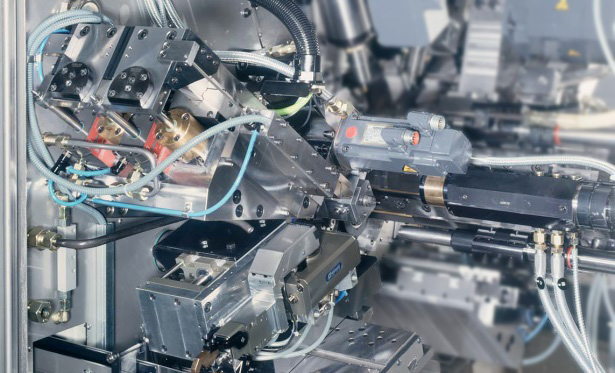

Again and again, Schütte has redefined the limits of what is possible with these automatic lathes: in terms of cycle times as well as precision. To achieve this, hydraulic cylinders from Hänchen with a resolution of 0.1 µm are used in the longitudinal slides.

- Extremely long maintenance intervals

- Space-saving construction

- Force and speed simultaneously, available at full power

Requirements for the hydraulic cylinders

- Compact design

- Position transducer for a resolution of 0.1 µm

- Very low-friction

- Limited installation space

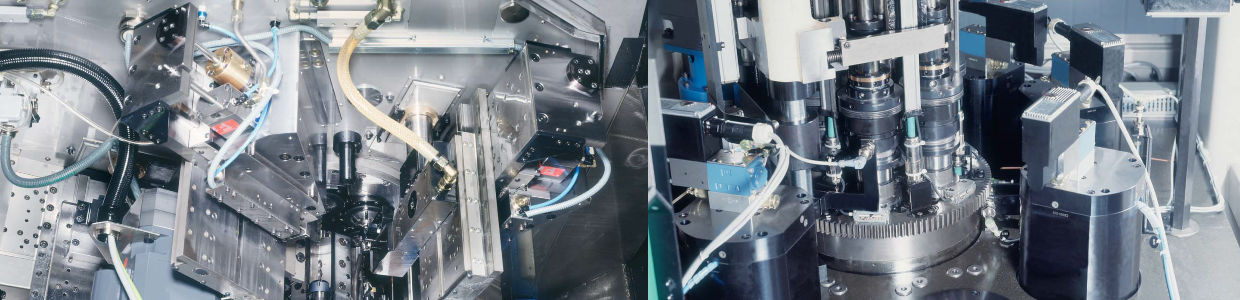

- Precision, more accurate than 1 μm

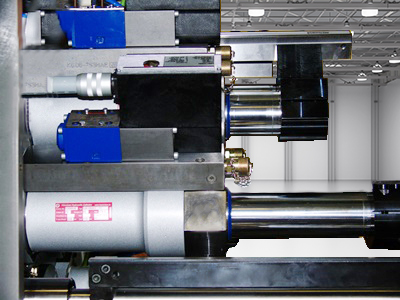

- High stability, as a seal replacement is very complex

Today, up to 8 spindles are used in one automatic lathe. They are arranged in a circle around the central axis of rotation. Since the installation space is very limited, the feed drives of the spindles are closely nested. This results in high demands on a compact construction of the spindle drive. A precision more accurate than 1 µm places special demands on the feed drives in the machines, which must combine accuracy, speed, force and compactness. This has long been a typical application for hydraulic cylinders. The precise linear drives for the longitudinal slides of these machines are supplied by Herbert Hänchen GmbH & Co. KG in Ostfildern. There are up to 15 cylinders per machine.

"We had massive quality problems with another manufacturer over a longer period of time," reports Dr.-Ing. Albert Herrscher, member of the management board at Schütte. "That's why we switched to Hänchen. Hänchen then designed a double-rod cylinder with integrated glass scale for a resolution of 0.1 µm as a longitudinal slide drive on our behalf. Since we have been using these cylinders, quality is no longer a topic of discussion." At the Cologne-based company, the hydraulic cylinder is the key component of a precise system. Other important components are the valve and the higher-level position control circuit, which, depending on the machine type, is addressed by an industrial PC with decentralised sensors connected with ProfiBUS V2 or a CNC control. From 1992 onwards, this replaced the technology of classic mechanical cam drives and so-called hybrid solutions with electromechanical units. For particularly long strokes, Schütte still uses electric drives. This is because, with the current state of the art, valves are the component that sets the physical limits of the technology due to a maximum flow rate of 25 l/min at 100 bar system pressure. Hänchen hydraulic cylinders could easily handle other dimensions here. In some machine types, the cross slides also contain a cartridge solution integrated into the slide with a single-rod cylinder. In this case, electronic compensation enables the necessary precision, while double-rod cylinders can be controlled particularly precisely directly due to their symmetrical construction. Because of the direct integration into the slides, the stability of these cylinders is particularly important, as a seal change or replacement would be very complex. Dr.-Ing. Herrscher adds: "With the Hänchen cylinders, that's no longer an issue! You can install them and forget about them."

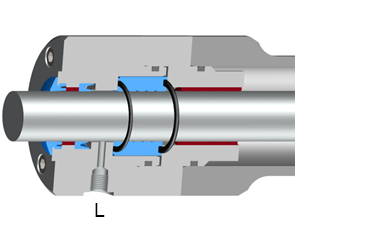

In addition to positioning accuracy, stability and power density, hydraulics offer further advantages: For example, the lines are located in the polymer concrete, which is used for the machine foundation for precision reasons, a form of integration that is not so easily achieved with electrical lines. This gives the customer a compact unit with only a few ports. The hydraulic linear drives described provide up to 4,500 N feed force to move the workpiece at up to 7,000 min-1 with a maximum torque of 50 Nm. Due to the extreme demands on precision, and because no lateral forces occur, the patented floating gap seal is used in the Hänchen cylinders supplied to Schütte. This "Servofloat® quality" operates almost friction-free. With extremely slow and very fast movements, it enables contactless pressure reduction to the outside and low leakage. Therefore, these cylinders offer the highest positioning and repeat accuracy and are stick-slip-free.

The sealing combinations work according to the following principle: When the system starts, a hydrodynamic oil flow is built up in the floating gap seal via the cylinder chambers, so that it centres itself radially around the piston rod in a metallic, contactless, "floating" manner. When pressure is applied, a bush made of steel deforms and forms a throttle gap, which acts as a non-contact sealing gap of a few 1/100 mm. However, this process only works with a production accuracy in the range of a few µm. Otherwise, the leakage would lead to high hydraulic losses. Leaking leak oil is returned to the fluid circuit without pressure via a collecting port. The absence of a touching, pressurised seal minimises the static and sliding friction in the cylinder. The floating gap seal only has a pressure-reducing function with minimal leakage. Therefore, the piston rod is guided by means of friction-optimised wear rings. Nevertheless, a cylinder with a floating gap seal can also absorb relatively high lateral forces. A decisive argument for cylinders with a floating gap seal is the price. Because this quality only differs in the lower permissible side loads from cylinders with hydrostatically mounted piston rod guide, but brings a price advantage of about 30%.

Image 1: Cartridge solution with a single-rod cylinder

Image 2: Multi-spindle automatic lathe

Schütte is the only company that uses hydraulics as a basic technology in multi-spindle automatic lathes. Only one of the 4 competitors worldwide also supplies a single machine type with hydraulic drive. "With this technology leadership, we can open up new performance dimensions for our customers," emphasises Dr.-Ing. Herrscher. Because as important as the price is, quality and precision are the more important standards for Schütte. In Cologne alone, the company employs 540 people, including around 60 trainees, and generates a turnover of around 80 million euros annually. In addition to multi-spindle automatic lathes, the machine manufacturer has specialised in tool and universal grinding machines, which it sells worldwide through subsidiaries in France, Japan, Spain, the USA and China with an export share of 50%. Particularly important foreign markets are Japan and Italy. The focus worldwide is on two divisions: The production of brass fittings as well as the automotive and automotive supplier industry. The member of the management board summarises: "There are both worlds and we use both technologies, which are comparable in price. A similar precision to hydraulics is possible with electric actuators. However, this requires compromises in the triangle of compactness, force and acceleration, which are not necessary when using hydraulic systems. We would therefore use hydraulics in further machines if there were no flow limitation in the valves. Because we have developed the necessary hydraulic expertise in the long term and master system integration. In this way, we have earned the trust of our customers in the long term. The hydraulic cylinders from Hänchen have made an important contribution to this."

Read more about Hänchen servo hydraulic actuators on our topic page: Servo hydraulic actuator - hydraulic cylinder with valves and sensor technology.

© Hänchen 2007