Low-pressure casting machines in the foundry

Industrial hydraulic cylinder

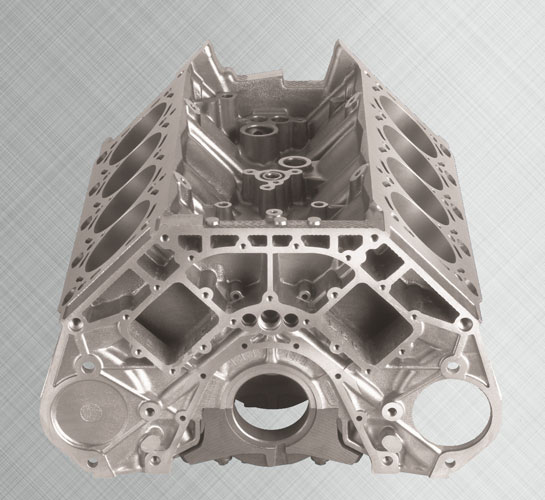

“Always lighter!” – the automotive industry demands this, especially from classic heavyweights in design: In particularly powerful cars, the cylinder crankcase and the engine block are now made of aluminium. This saves around 70 kg of vehicle weight. Kurtz GmbH in Wertheim develops and produces casting machines for such aluminium engine blocks that meet the special requirements of the light metal. This also means the highest demands on the components of these plants. They must meet extreme requirements for heat and corrosion resistance.

This applies in particular to the hydraulics, which have to combine heavy-duty work with the highest precision in the casting machines. Hydraulic cylinders from Herbert Hänchen GmbH from Ostfildern fully meet these requirements and are therefore a standard component at Kurtz.

- High repeatability

- Low stick-slip movements

- Seals for a high working temperature of the HFL fluid

- Keeping foundry sand away

- Hydraulic cylinder of the 120 series

- Bore 200 mm, rod Ø 100 mm, stroke 1,800 mm

- Attachment part: Circular flange head side

- Integrated displacement measuring system

- Seals for HFC fluids

- Cover type Servocop®

- Metal wiper ring against dirt from the outside

An increase of around 30% this year shows that Kurtz, with its foundry plants for aluminium low-pressure die casting, is meeting the needs of the market. The machine manufacturer also offers the know-how of its own contract foundry, which is also a testing ground for new technologies. A Europe-wide growth in aluminium consumption of 9% to two million tonnes last year demonstrates the potential of this market. In Germany, three-quarters of the cast light metal goes into the transport sector. Unlike steel foundries, aluminium does not involve extreme pressures when pressing into the mould, during the so-called shot. In the melting furnace, a pressure of only 1 bar is applied, which allows the liquid metal to flow through a riser pipe into the mould. In this way, the melt enters the die with low turbulence and therefore without air pockets. In addition, the solidification of the liquid aluminium becomes a controllable process, which is decisive for a pore-free product, which supports post-compression. Finally, the entire process can be visually monitored from the outside, as the mould is open due to the low-pressure process.

Removing the Mould

The real mechanical challenge, however, is not the casting process including post-compression, but the removal of the mould. This is because the metal shrinks by up to 7% during cooling. In the case of an eight- or twelve-cylinder V-engine, up to 11 hydraulic cylinders must therefore apply the necessary force retracting to remove the mould parts. In addition, there are five further hydraulic cylinders for positioning the mould. This hydraulic system moves up to seven mould parts. The linear drives are used in the upper pull, for tilting, in the quill pull, for swivelling the quill and for the face and side pulls. In total, a force of 50 t must be applied in order to pull off the moulds wedged by the shrinkage of the engine block. Heat resistance and resistance to an extremely aggressive atmosphere are particularly important here. In addition, high demands are placed on performance and the precision required for synchronisation, as any asymmetry of the forces during removal additionally wedges the moulds in the cavities of the engine block.

High performance without special design

In these foundry machines of the company, which was founded in 1779 as a hammer mill, hydraulic cylinders from Hänchen are used. These linear drives offer the possibility of taking very special problems into account constructively without expensive special designs, thanks to the modular system. The product selection in the 3D-CAD of the Hänchen configurator allows the entire product range of the family-owned company from Swabia to be used. The decisive factor for Kurtz was the optimal cost-performance ratio, which is only possible with this product system. Due to the high demands on precision, repeatability and practically stick-slip-free movements, the choice fell on the series 120 with a pressure range up to 150 bar in Servocop® quality, which is also suitable for particularly fast and very slow movements. This seal and guide combination is characterised by optimised friction properties. A synthetic piston rod guide with leak oil port enables the use of particularly low-friction seal combinations, consisting of a Teflon seal, a PU seal and a wiper ring.

Challenge HFC-seals

This standard version had to be adapted to the special conditions: Since temperatures of up to 350° C still occur outside on the moulds in the foundry itself, only HFC seals are used in the special version, as these can also easily cope with a high continuous working temperature of the HFL fluid. A metal wiper ring also ensures that the foundry sand does not penetrate into the seal area in the first place, where it can damage seals and the piston rod. These modifications were possible at Hänchen on the basis of CAD variant production without the effort of a new design. For the foundry machines, a high-precision magnetostrictive position transducer BTL 5 with a repeatability of a few μm was also installed, which is integrated in the hollow-bored piston rod in a protected manner, works without contact and is therefore wear-free. This variant is part of the standard range of servo hydraulic actuator. The position transducer supplies the analogue basic data for the plant control and also works as a 'virtual limit switch'. In the aluminium low-pressure die-casting line for the production of engine blocks, the entire process is controlled and visualised in real time via a PLC. In this way, many work steps are optimised by Hänchen's hydromechatronic system: First, the lower die half is closed, then the hydraulic cylinders move the closing unit. The metal then flows into the casting mould. After cooling, the tension cylinders open the closing unit. Finally, the finished casting is removed. Especially in three-shift operation, this process places the highest demands on the stability of the hydraulic cylinders. Here, the products of the hydraulic specialist from Ostfildern near Stuttgart demonstrate their full performance.

© Hänchen 2004