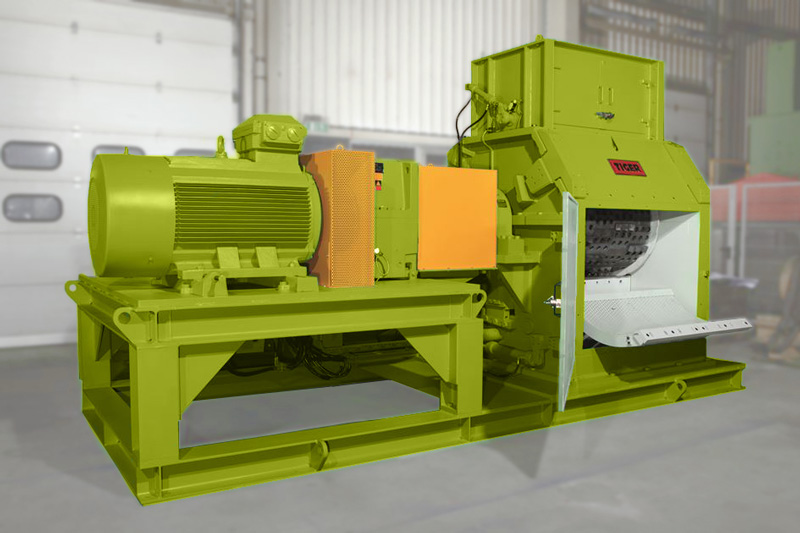

Single-shaft shredder in recycling plants

Industrial hydraulic cylinders - low-maintenance and durable

The Pallmann Maschinenfabrik GmbH & Co. KG group of companies is a leading manufacturer of size reduction machines and plants for the synthetic and recycling industries. These are custom-designed according to customer specifications or manufactured as standard plants. The recycling of waste material requires high forces to break up stable material composites.

Since unforeseen foreign materials can enter the shredding process, the machines must withstand unpredictable mechanical loads. Furthermore, precise adjustment of the particle sizes to be achieved is important for the most accurate separation of the various recycled end products. All of this makes hydraulics a key technology in Zweibrücken.

Herbert Hänchen from Ostfildern near Stuttgart is a proven partner for hydraulic cylinders.

- high manufacturing accuracy

- long maintenance duration

- Overall long service life

Resistant to:

- dust and dirt

- chemically aggressive substances

Recycling places high demands

Long maintenance intervals for the hydraulic cylinders

- the coarse shredding to a size of maximum 150 mm,

- the separation of the composites,

- the fine granulation and, if necessary, the finest granulation.

Precision in a harsh environment

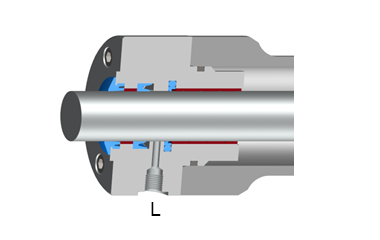

Hydraulic cylinders: low-friction, low-wear, durable

Cover type Servocop® for hydraulic cylinders

enables low-wear use

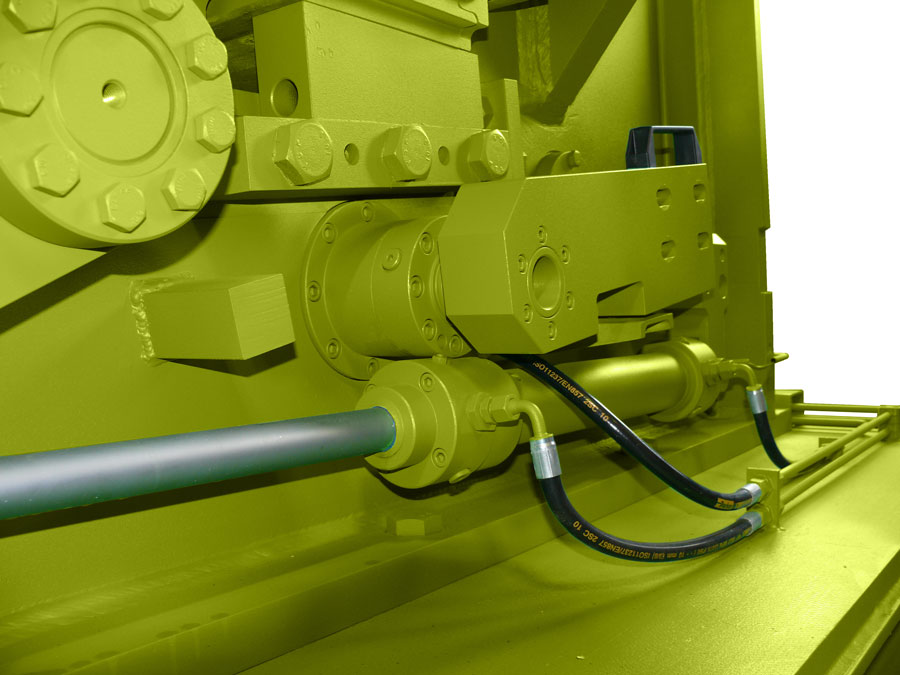

Hänchen hydraulic cylinders in use

under high static forces and vibrations

The machines shred up to 4 tonnes of all materials that can be cut into grain sizes of maximum 20 mm every hour. Solid, wave-shaped rotor ripping bars move - driven by a 355 kW motor - past stator ripping bars. By reversing regularly, i.e. changing the direction of the rotor, they sharpen themselves automatically. Here, a first Hänchen cylinder is in use, in the middle of the inlet flap area. A generously dimensioned screen is installed in the lower housing of the machine. This holds the material in the working area until it can be discharged through the screen perforation. Two further cylinders move heavy screens, which are folded out if required or when the blades are changed. These hydraulic cylinders are also constantly exposed to environmental influences from dirt and vibration. A further hydraulic cylinder pushes the blade bar outwards for maintenance purposes: it is installed with a stroke of 1700 mm, a rod diameter of 50 mm and a bore of 80 mm. In normal operation, the piston rod is constantly extended and the shredded recyclable material constantly falls over the cylinder. This results in high static forces and vibrations, which place a particular load on the seal combination. Apart from a special paint finish and a special position of the bushes, this component is also a catalogue product at Hänchen, which has a very positive effect on the price and reliability. The last cylinder moves a hydraulic motor to rotate the rotor for maintenance purposes. As with all other comparable plants, the hydraulic system, including the power unit and generously dimensioned accumulator, is supplied by Pallmann for the Tiger.

The specialist for material shredding up to a hardness of 4 can - as now in recycling technology - work together with customers to investigate shredding processes, test the behaviour of new materials or innovative processes or develop new machines, plants or other shredding solutions. In addition to the extensive know-how in application-typical mechanics, hydraulics, electrics, materials science, electronics, process optimisation, control software and sequence programming, a special plus is also available: its own technical centre with 150 different machines. Here, tests can be carried out and prototypes can be tested. This enables Pallmann to achieve a reliability and performance that is unparalleled on the market. This is demonstrated by tyre recycling, where the Tiger with the Hänchen cylinders is also used:

"Ten years of three-shift operation without any problems show that our concept works," reports Dirk Dietrich proudly. The hydraulic components from Hänchen are an essential quality component.

© Hänchen 2014

Read more in the articles published on the application

|

Force and precision - hydraulic cylinders are a quality component in recycling plants |

November 2016 |