Mould oscillation in the steel mill

Custom hydraulic cylinder

"If every standstill costs a small fortune, then quality is mandatory!“ This is how Dipl.-Ing. Ulrich Grziwotz, team leader of the Service & Development team in the continuous casting division at ThyssenKrupp Steel AG in Duisburg-Bruckhausen, describes the requirements for the components of his plant.

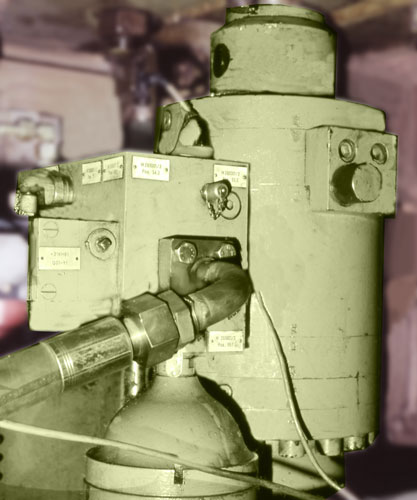

Of particular importance are the machine head with the mould and the lifting table devices from SMS Demag AG, as well as the hydraulic cylinders from Herbert Hänchen GmbH integrated therein. This is because the oscillating movement of the mould, driven by the hydraulic cylinders, ensures optimum quality and the problem-free flow of 3 million tonnes of high-tech steel per year.

The 25 t mould oscillates at up to 3 Hz with any desired vibration profile. The guiding accuracy of the machine head in the vertical and horizontal directions, as well as the reproducibility of the processes, meet the highest quality requirements. At 1.5 Hz in normal operation and a maximum frequency of 3 Hz, each linear actuator completed 200 million load cycles in 6 years before the hydraulic cylinders were delivered to the Hänchen plant in Ostfildern for inspection.

- Maintenance cycle of 6 years

- Small amplitudes of 3-4 mm

- 200 million load cycles without inspection

- Wear-free sealing system

- Oscillation of a 25 t mould

- 3 Hz with any oscillation profile

- Fail-safe hydraulic cylinders

- Long maintenance cycles

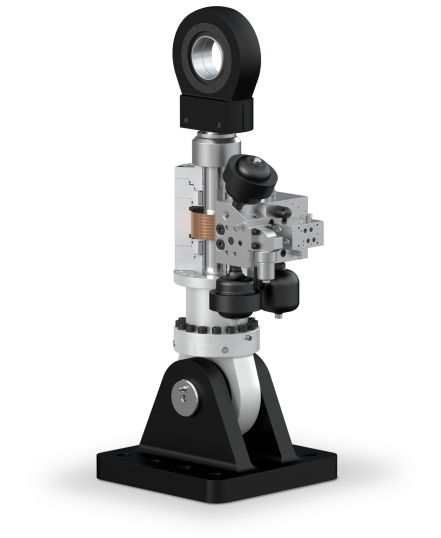

- Hydraulic cylinder of the series 320

- Force of 400 kN

- Servofloat® quality for a wear-free sealing system

- 80 oscillations per minute with a stroke of ± 3-4 mm

- Maintenance cycle is 6 years / 200 million load cycles

In order to avoid such a breakthrough in continuous casting, the steel industry developed mould oscillation in the early 1950s. The oscillating movement of the mould ensures that a flux, the casting powder, is introduced between the mould wall and the strand shell for lubrication purposes.

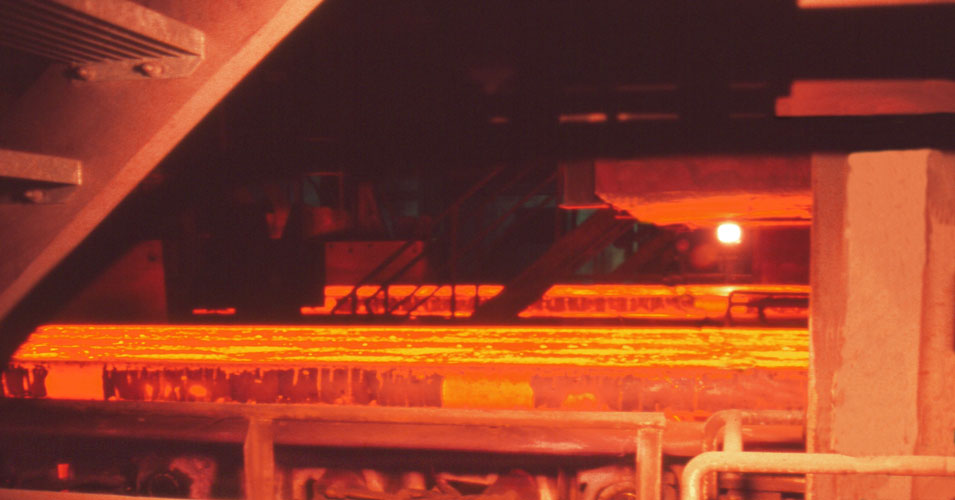

After many development stages, in which SMS Demag played a significant role in shaping and advancing, the current state of the art is hydraulically driven resonance oscillation. At ThyssenKrupp Steel AG in Duisburg-Bruckhausen, a hydraulically operated short-lever oscillation from SMS Demag AG is in use. In the mould, the rectangular strand, which is liquid inside and solidified on its surface, is formed from the molten steel flow. The subsequent strand guide supports the strand. The strand is completely solidified under spray water cooling. This strand guide consists of 13 groups of rollers, the so-called segments, which fulfil several tasks: They prevent the bulging of the steel strand to a dimension greater than a defined thickness of 215 mm with a width of 1,800 to 2,600 mm. And they align the strand from the vertical to the horizontal – with a radius of 9.3 m. In addition, they enable the cooling of the strand by water so that the steel flow is completely solidified when it is cut into slabs at the end of the casting machine.

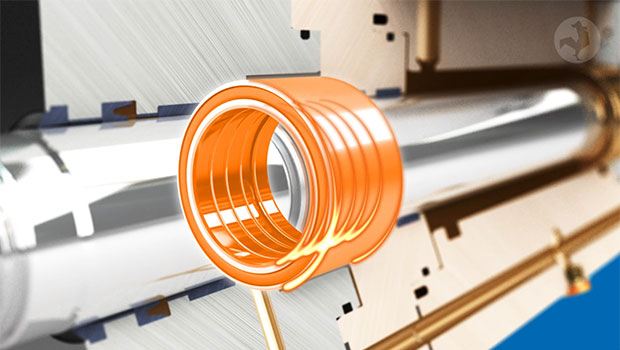

The hydraulic mould oscillation developed by SMS Demag AG ensures that the mould always has a relative movement in relation to the steel strand through the use of the hydraulic cylinder. It oscillates continuously in a vertical direction, whereby the movement simultaneously serves to introduce the casting powder as a lubricant between the strand and the mould wall. Each of the two lifting tables in use is moved by two Hänchen hydraulic cylinders of the 320 series in Servofloat quality with the patented floating gap seal.

The patented floating gap seal of the Servofloat design is used in the controlled servo hydraulic actuators, which apply a force of 400 kN. A steel bushing follows the radial deflection of the piston rod with a sealing gap of a few 1/100 mm, which is practically constant over the entire pressure range. However, this process only works with a production accuracy in the range of a few μm, as otherwise the leakage leads to high hydraulic losses.

Hydraulic cylinders in Servofloat® quality offer the highest positioning and repeat accuracy due to their negligible friction, are stick-slip-free and are suitable for extremely slow and fast movements. Due to the practically friction-free design, such a hydraulic cylinder does not wear out even in extreme long-term use. This corresponds to the requirement profile in which the highest availability has top priority. In particular, high demands are placed on the cleanliness of the fluid: The filters are replaced as required, and the two pumps for the working pressure of 260 bar are replaced every 35,000 hours. A particle count and the replacement of the servo valves take place once a year. Three-dimensional measurements on the lifting table with an accuracy of 10 μm, which record and display any changes in the oscillation movement, also serve to ensure quality. Originally, we planned to maintain or replace the hydraulic cylinders annually,” reports Dipl.-Ing. Marc Ramacher, the specialist coordinator responsible for maintenance at ThyssenKrupp Steel AG. “However, the replacement cycle for general overhaul was initially increased to two, then to four and now to six years. Even after this time, we did not have to completely replace the Hänchen hydraulic cylinders. It was enough to send them to Hänchen for inspection and general overhaul.

- White strip steel, for example for beverage cans, which poses a particular challenge with its very thin sheet thickness.

- Steel for dynamos and transformers.

- Thin sheet metal - for example for the aperture grilles of televisions.

- IF steel for the automotive industry.

- Other special steels that differ in hardness, brittleness and composition.

At the end of the casting machine, the strand is cut into slabs transversely and longitudinally with fully automated cutting torches. Transport rollers and cranes bring the slabs to the warehouse. On the way from the mould to there, they go through the entire color spectrum from white heat to all shades of red heat to the steel gray that also have the blanks of the hydraulic cylinders that move the tons of moulds to produce new quality steel.

© Hänchen 2006