Dancer control for dynamic yarn tensioners in force retracting-controlled unwinder

Ratio-Drive® Fast drives optimise dancer control in textile machines

Hänchen was commissioned to optimise the dancer control of a textile machine for the production of reinforced strips. The existing winding station of the winding plant was equipped with a hydraulic and fast drive control system.

The customer requirement for Herbert Hänchen GmbH was to reliably fulfil all previous tasks of the creel. At the same time, the parameters with regard to accuracy and user-friendliness of the thread tension should be significantly improved. In the future, the force retracting control will be regulated quickly and dynamically via hydraulic cylinders. In addition, the adjustment of the thread tension in the winding plant should not be carried out by exchanging weights as usual, but via software parameters.

With this optimisation of the dancer control, the customer achieves high flexibility by saving changeover times, higher accuracy, better process reliability and more dynamics. This enables, for example, the use of a robot.

- Electrically directly controlled thread tensioner

- Software-based control

- Electrohydraulic dancer control

- Individually configurable parameters

Technical requirement

- Maximum tolerance for the thread tension to each other of ± 1,500 cN

- Speed from 300 to 400 m/min

- Thread tension steplessly adjustable between 4,000 cN and 55,000 cN

- Improvement of process reliability

- Consideration of the ambient conditions with temperatures of 0 - 40 °C and a humidity of 95 %

Implementation of the dancer control from Hänchen, according to customer requirements

Hänchen equips the complete creel with modern electrohydraulic drive technology and software-based control of the dancer control with individually configurable parameters.

- Force-controlled thread tension via the sensor technology of the cylinder

- Series 320 Servofloat cylinder with displacement sensor

- Speed-controlled take-off roller

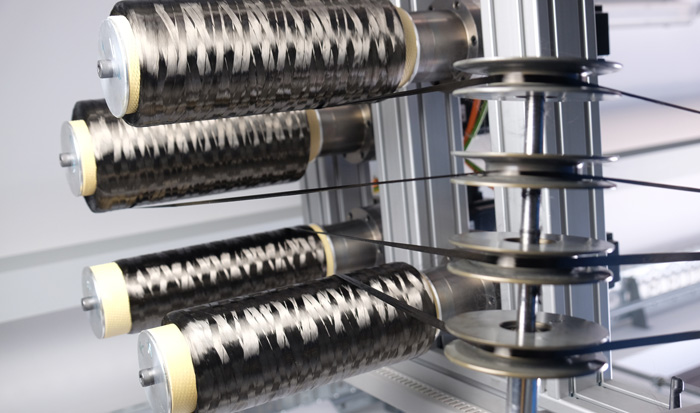

In textile machines such as braiding and weaving machines, winding or tape laying plants, the material to be unwound is placed under tensile stress for processing. Winding material can be fibres, threads, yarns, strips and other materials. It is important that these lie evenly in the final product. The unwinding takes place from the so-called creel, a frame in which the bobbins with the wound material are located.

The selection of the correct unwinding technology is decisive in order to be able to manufacture the products in the required quality. If only one thread in the fabric has too little preload, it will sag and, in a problem case, render the entire fabric unusable. The avoidance of such errors is conventionally achieved by braking the bobbin plate. This is done, for example, mechanically, with magnetic brakes or pneumatically. Such friction point preloads are mainly used for normal "fabric yarns", as these threads have a higher elongation coefficient. For threads such as aramid, polyester, polyamide, polyethylene and highly rigid threads such as carbon, basalt or steel wire, on the other hand, dancer controls are used.

What is a dancer control?

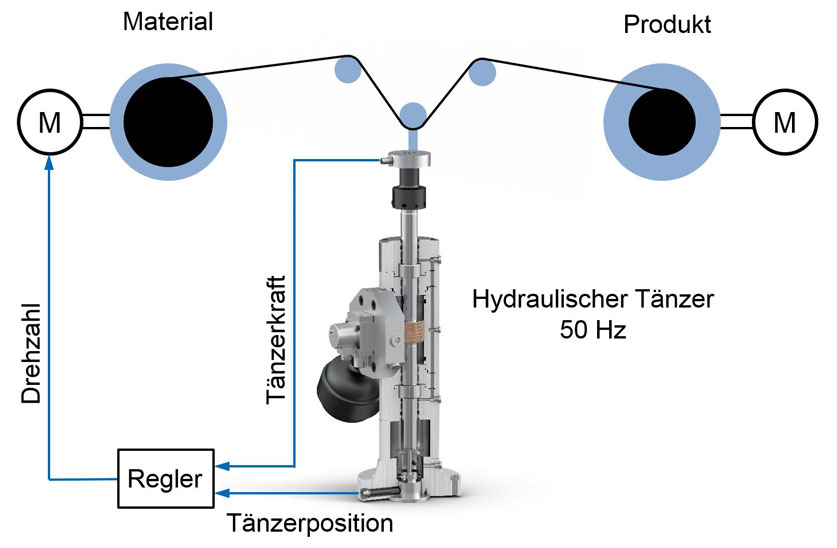

In winding and unwinding processes in textile machines, tearing of the fibre or tape during the unwinding or winding phase must be prevented. A vertically freely movable guide roller, the so-called dancer, is used. This regulates the preload of the winding material. The force retracting for the thread tension must always be constant. This is independent of different bobbin diameters, unwinding speed, possible material irregularities and other parameters.

In creels, the thread is transported from the unwinder to the machine via a pulley, similar to the principle of a block and tackle, by drive motors. The dancer control regulates the force retracting of the thread and the speed of the motors. The winding material is guided over the dancer, which applies a predefined force. In conventional bobbin station solutions, the "block and tackle" is operated by placing different weights on it in order to control the force retracting of the thread. The changes in preload are compensated by upward and downward movements. This process is called dancing.

The problem with the previous mechanical dancer control is the manual replacement of the weights to adjust the preload. Different tensile stresses require different masses by replacing the weights.

This means: open the machine, replace the weight accordingly, close the machine, start up. Additional mass means more tension and vice versa. If the application requires high dynamics due to rapid acceleration and braking processes, these bobbin frames regulated by weights are often no longer sufficient. This manual replacement is very time-consuming. But also the accuracy of the force retracting controls leaves something to be desired. An optimised dancer control provides a remedy.

Hänchen offers two technical solutions

In order to control the thread preload more flexibly and precisely, Hänchen offers two options: an electrically directly controlled thread tensioner or an electrohydraulic dancer control. Fast, electrically controlled thread tensioners can directly adjust the preload of the thread with small motors with low moving mass to the bobbin diameter using the motor torque. Especially in machines with many bobbins, this solution allows a cost-effective alternative to the force retracting-controlled thread tension of the unwinder. Due to the ability to also roll back long thread sections, the application is ideal, for example, in tape laying systems.

Another way to adjust the thread tension, especially in the range of higher tension forces, is the hydraulic dancer control with preload by hydraulic cylinder for controlling force and displacement.

The hydraulic dancer control system

In the present customer application, the hydraulic solution was selected to process the very rigid and heavy yarn. For this purpose, Hänchen regulates the yarn tension to the machine with the aid of hydraulic cylinders.

First, the experts at Hänchen determined the required functional values with regard to accuracy, unwinding and reaction speed at the winding station defined by the customer. The goal is a maximum tolerance for the thread tension to each other of ± 1,500 cN. This concerns the deviations in the thread tension during the winding process at a constant speed of 300 to 400 m/min and the tolerance between threads made of two different materials.

During acceleration, the product requires material that is applied with a defined thread tension. This thread tension is monitored by the sensor technology of the cylinder in a force-controlled manner. The hydraulic cylinder moves upwards or downwards in a position-monitored manner in order to apply the defined force and release the thread with preload. The material roll, which is controlled at a constant speed, must react accordingly.

For robust threads, the hydraulic dancer control can be optimised by using additional speed-controlled take-off rollers in order to obtain a larger retraction range of the thread. For this purpose, a speed-controlled take-off roller is installed between the cylinder and the material roll, which ensures that the material roll does not become blocked. Due to the actuators networked in the control circuit – cylinder and take-off motor – in coordination with the motor of the material roll, voltage fluctuations can be compensated for at any time, which prevents the material roll from blocking and thus the thread from tearing.

The force that was previously manually applied as weight for the thread tension can now be easily set by the machine operator on the system. This enables a better targeted reaction if an error is diagnosed during the monitoring of the thread tension. Any values between 4,000 cN and 55,000 cN are possible here. And the cylinder does the job quickly and dynamically thanks to its reaction time of up to 20 ms at 50 Hz.

and arrange a consultation appointment!Use the convenient postcode search to find the responsible contact person for you.

Advantages of the hydraulic solution

The greatest advantages of this hydraulically supported dancer control system are user-friendliness and occupational safety. What the machine operator previously had to laboriously mount manually on weights in the machine, he can now enter steplessly on a display without physical strain and also obtain a much more accurate result. This reduces or eliminates set-up times for the end user. And above all, reliability has increased due to the accuracy of the measured values. In addition to the main variable determined via the force transducer on the cylinder, values from the electric motors are also queried and incorporated into the process. These parameters are very meaningful for quality assurance. This allows the process reliability to be significantly improved. The cost savings are also of interest to the end user: While previous solutions resulted in several hundred meters of thread being rejected at the unwinder during start-up due to the dancer settling in, this thread loss has been reduced by a third thanks to the hydraulic control. And last but not least, all output measured values and data can be used for further research and development.

Define specifications

For the calibration of the force measurement on the thread material, a weight was previously attached directly to the thread in front of the roller in the machine and the thread tension was read on the display. This made errors in the thread speed possible, especially due to the out-of-round spools and the coarse thread structure. For a solution with hydraulic cylinders, Hänchen determined the thread tension using three calibrated force transducers per thread on the deflection rollers. The Hänchen solution enables a spool tension with a bandwidth of 1,500 cN and was proven by measured values and curves. Ultimately, this leads to much more accurate values, which means that measurement errors can be avoided in the future.

Recognize challenges

The accuracy requirements for the dancer control system proved to be a major challenge during the tests. Especially due to the tensile stress bandwidth specified by the customer. The roller position of the deflection rollers and the position of the thread or the multi-part threads as well as their properties - round or flat - posed additional challenges. The large forces in connection with high dynamics had to be taken into account. The decades of high competence for the combination of hydraulics and electronics was the key to success for the Swabian company. This is especially true since three drive systems are used in the spool station: two electric motors on the spools - and of course the hydraulic cylinder. These three axles work with and against each other, which makes the control complex. For example, the thread spool has to apply a constant counter-torque so that the spool station does not transfer too much thread to the processing with too little tension.

Solve challenges

Based on the specified parameters, i.e. a drive for the thread spool and a synchronous motor for the deflection roller, Hänchen was able to assume a hydraulic system pressure of 250 bar, a static weight force on the cylinder of over 5 kN and a dynamic force of around 4.5 kN. The ambient conditions are temperatures of 0 - 40 °C and a humidity of 95 %. The hydraulics specialists defined a cylinder from the Servofloat 320 series with a displacement sensor as the actuator. With this hydraulic solution, however, plants with much greater forces can also be implemented.

An exciting project for the hydraulic specialists at Hänchen. In addition to the design and production of hydraulic products, Herbert Hänchen GmbH also provides cross-technology consulting, engineering and the realisation of complete drive solutions.

Jörg Beyer, mediaword

© Hänchen 2020