Ratio-Drive® test field equipment

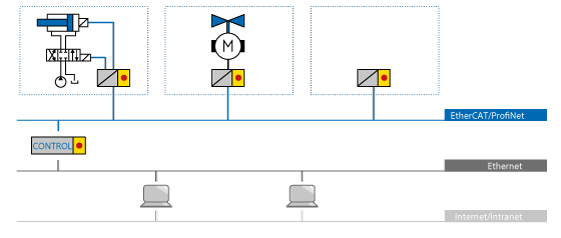

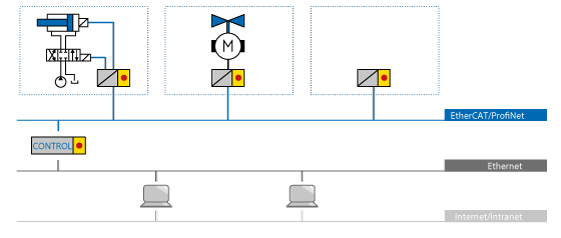

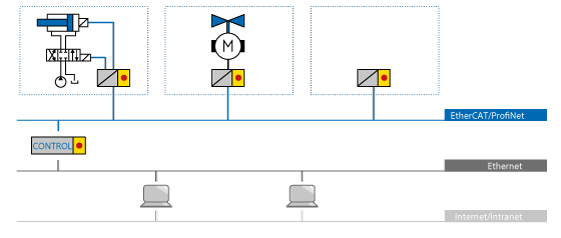

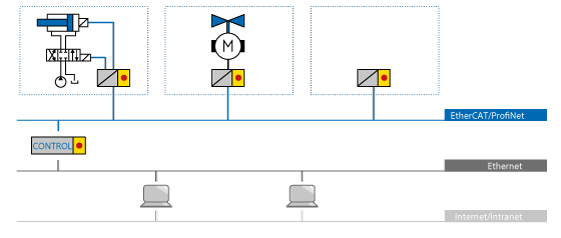

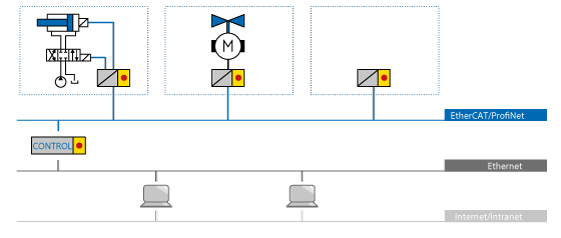

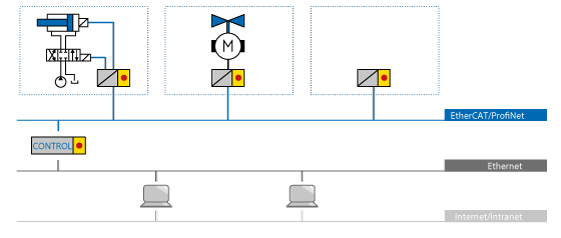

We design the complete test setup, from the individual component and quickly convertible test fields to the complex test machine. Fully automatic, precise, software-controlled test machines and functional test stands deliver pinpoint material tests, structural and functional tests, as well as end-of-line test stands for quality control at the end of production. Test fixtures help to optimise manufacturing processes, increase quality and process reliability and reduce the costs of labour or complaints.

Here you will find application examples of the areas of application for test components such as hydraulic cylinders, hydraulic test cylinder and clamping units, as well as the implementation of individual test machines.

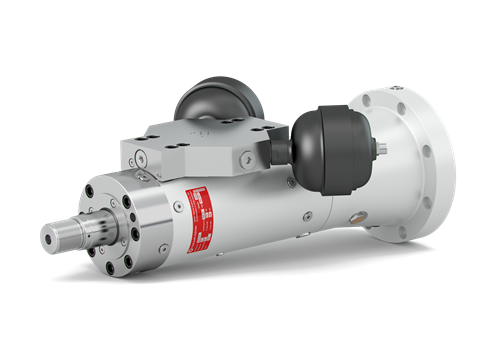

Here you will find examples of the use of hydraulic test actuators, cylinders with hydrostatic bearings and servo hydraulic actuators in test stands. Our rod clamping units are also used in test machines to secure and lock the plant when not in use and to protect the test specimen in the event of a power failure.

These and other components for test engineering ensure precise testing processes and reliable protection of plants during operation and standstill.

Hänchen is your reliable partner for customized solutions in test stand technology. Our expertise ranges from the development of individual components for test stand construction to the realization of complex test machines. The know-how from countless individual in-house and customer projects makes Hänchen a reliable quality provider of complete test stands, test fields and complex test machines today. This reflects our many years of competence development - starting with cylinder construction, expanded to include electronic components and complete drive systems. In the meantime, Hänchen offers its customers entire machines, including drive axes, safety catchers, frames and machine elements.

Since its beginnings as a manufacturer of precise test actuators, Hänchen has undergone an impressive development. Today, we combine comprehensive expertise and decades of experience to offer our customers integrated solutions - from individual test fields to complete test machines.

Hänchen stands for precise, innovative and tailor-made solutions in test stand construction - a partner that combines competence, experience and quality. Entrust us with your most demanding projects and benefit from our comprehensive know-how.

Hänchen offers one of the world's largest ranges of hydraulic cylinders for test stand construction. With our two series – the servohydraulic drives of the series 300 and the test actuators of the series 320 – as well as the various seal and guide concepts, we cover all application areas for testing tasks with hydraulic cylinders.