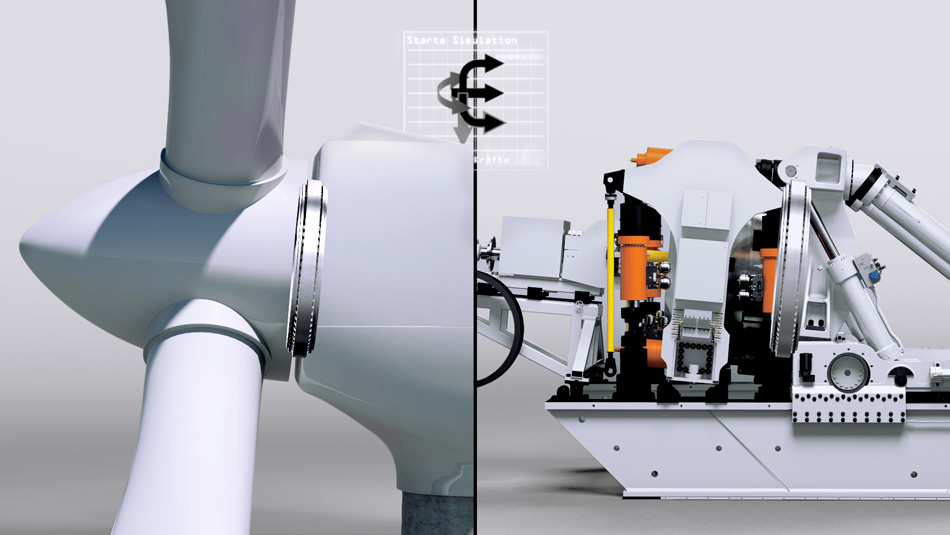

Large bearing test stand for wind turbines

Hänchen hydraulic test cylinder as test actuator

Approximately 40 GW of wind energy capacity is installed worldwide every year. Increasingly larger plants are being used: 5 MW is now common in the offshore sector, and the 6 MW limit has already been reached. High-performance bearings from Schaeffler Technologies ensure that the bearings operate reliably throughout their entire service life. The key to the impressive quality of these bearings, which currently have an outside diameter of up to 3,200 mm, is the in-house ASTRAIOS testing system.

Hänchen hydraulic test cylinder as test actuator move this giant that tests the rolling bearings inside and out. It is one of the most modern, largest and most powerful large bearing test stands in the world.

- Test machine cylinders from Hänchen move one of the largest testing facilities for bearings worldwide.

- Powerful and precise with Hänchen test actuators.

_neu.jpg?m=1722328695)

The linear drive solution supplied by Hänchen

- 8 double-rod test actuators - 4 radial and 4 axial cylinders

- Hänchen series 320 with an output of up to 1.5 MN

- Stroke of 1 mm and 7 mm

- Integrated inductive position transducers

- Design and supply of the valve block

Originally, the ASTRAIOS large bearing test stand was intended to test all bearings from wind turbines with up to 3 MW. The value was later raised to 6 MW, as large plants are increasingly being used due to offshore technology. The specific plant for a customer was the starting point. Each test cycle of ASTRAIOS adheres to the respective key data of the customers and to the coordinate system for loads of Germanischer Lloyd and takes into account the corresponding forces and moments. The plants have bearings with an outside diameter of 3,200 mm. The 16 m long, 6 m wide and 6 m high test stand accommodates individual, rotor and blade adjustment bearings up to 3,500 mm outside diameter with a weight of up to 15 t. In the past, only tests up to 700 mm were possible. With the current plant, calculations up to 7,000 mm can be checked with high accuracy by extrapolation.

Eight axles in the form of hydraulic cylinders are used in the tests to simulate the three-dimensional tumbling motion. 300 kW of electrical and 600 kW of hydraulic power enable the realization of the following test parameters: A torque of 150 kNm at a nominal speed of 12.4 min-1 and a maximum speed of 60 min-1. The axial force covers the range of ± 6 MN, the radial force ± 4 MN. The test forces result from the wind pressure for an output of 6 MW, from shear forces due to greatly differing wind speeds on the ground and at altitude, and the pitching moment in gusts. They act on the projected area of the rotor and via the levers of the rotor blades, which are over 75 m long. ASTRAIOS therefore works with a static pitching moment of ± 15 MNm and a dynamic pitching and yawing moment of ± 5 MNm. The measured variables force, moment, speed, temperature, flow rate, position, displacement, vibration and particles are taken into account. 300 sensors record these parameters, 100 of them at a 1 kHz clock rate, the others at 10 to 100 Hz. A total of 8 double-rod test actuators from Herbert Hänchen GmbH perform the linear movements.

Four hydraulic radial cylinders and four axial cylinders are attached to the load frame. They generate the real loads and moments that occur in a wind turbine. A pump system with power levels of 200 kW, 400 kW and 600 kW drives these actuators. The fundamental frequency of the plant is 1 Hz, with force superposition vibrations of up to 10 Hz are present. The radial cylinders simulate the weight of the rotor hub with the rotor blades of over 100 t. They typically operate with a stroke of 7 mm. Each of these radial cylinders in the Hänchen series 320 has an output of 1 MN. The axial cylinders generate the wind loads with an output of 1.5 MN, which consist of the static axial load and the dynamic pitching and yawing moments. The stroke of only 1 mm proves the high performance of the Servofloat® floating gap seal from Hänchen. Increased abrasion was eliminated by optimising the wiper rings. "We have had very good and constructive cooperation with Hänchen on this and other tasks, even after the sale and installation," emphasises Korn.

The test machine cylinders, which are controlled via force and displacement, are ultimately complete linear actuator. An important element is the integrated inductive position transducers. The very elaborately designed valve block also plays a significant role. The hydraulics specialist from Ostfildern near Stuttgart was responsible for the integration of the entire linear actuator here. This sophisticated overall concept allowed start-up without pre-start-up. "Everything worked immediately," emphasises the Head of Test Stand Construction. "That is very high engineering skill."

The good cooperation between the two companies was the basis for a superlative test stand that has caused a worldwide sensation. Schaeffler, as the client, is a world-leading supplier of rolling bearings and linear products as well as a renowned supplier to the automotive industry for precision components and systems in engines, transmissions and chassis. With around 79,000 employees worldwide and sales of around €11.2 billion, Schaeffler is one of the largest industrial companies in family ownership. Herbert Hänchen GmbH, also founded in 1925, is a family company that has been supplying hydraulic cylinders to its customers all over the world since 1952 with 210 employees. For many applications, the drive specialists offer series solutions without having to resort to expensive special designs with a high prototype risk.

© Hänchen 2014

Our competence as a manufacturer of test stands and test machines

Complex in-house and customer projects make Hänchen a reliable quality provider of complete test machines today. This reflects our many years of expertise - starting with cylinder construction, expanded to include electronic components and complete drive systems. Hänchen now offers its customers entire machines, including drive axes, safety catchers, frames and machine elements.

- Extensive experience in special machine construction of hydraulic and electrical special machines

- Experience in the systematised, individual design and realisation of customer projects

- Measurement, control and regulation technology, real-time control, measured value acquisition, sensor technology, fieldbus connection and evaluation

- Development of proprietary modular software, including graphical interface for control and regulation as well as communication at process level

- Extensive safety concepts up to PLe in accordance with the Machinery Directive, CE conformity, safety software

- Countless project planning in the field of test stand construction and the development of complex test machines