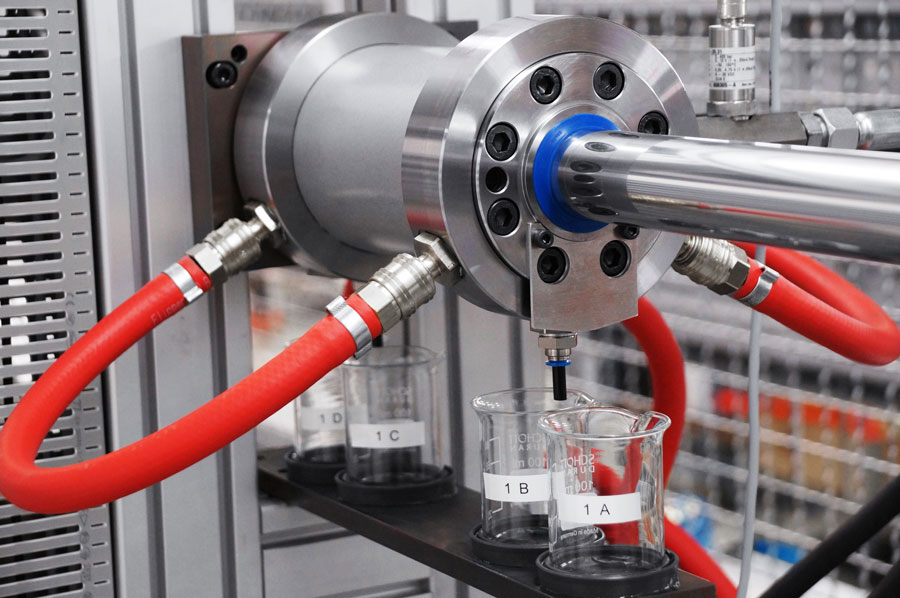

Test machine for seals and rod surfaces

Ratio-Drive® seal test stand

To determine the characteristic values of a seal, seal test stands are suitable, with which a wide variety of operating conditions can be simulated. The focus is often on the friction force of the seals, tightness on rods and shafts, temperature behaviour and wear.

"It all began with the idea of testing seals for our own hydraulic cylinders efficiently and practically," reports Dipl.-Ing. Klaus Wagner of Herbert Hänchen GmbH. Hänchen now designs and produces servo-hydraulic test stands for seal testing in research and industry in its special machine construction division. The individual test stands are implemented electrically or hydraulically, depending on the requirements of the seal manufacturer. On request, Hänchen develops and manufactures customised special machines for industry and test engineering in special machine construction.

We would also be happy to visit you in person.

- In-house experience in testing seals

- Comprehensive consultation

- Individual concept according to customer requirements

- Implementation of only required functions saves costs

- Many decades of know-how in hydraulics

- Test stand construction including CE

Test stand technology

Test machine requirements

- Complete test machine according to MRL

- 4 axles, each with 2 test rods, that can be moved independently of each other

- Endurance test 24/7 over 300 km

- Wear measurement of rod surfaces and seals

- Friction force determination based on VDMA 24577

- Leakage testing of individual seals and seal cascades

- Testing of stick-slip behaviour

Technical implementation of the seal test stand

- 8 pressure chambers, up to 600 bar adjustable pressure

- Water cooling for constant temperature in the test chambers

- Separating safety device

- 4 double-rod cylinders, series 300, Servocop®, 50 / 40 / 650

- Force transducer on test rods for friction force determination

- Software individually adapted

- Safe test stand control on Beckhoff system

Test parameters of the seal test stand

Seal testing process

Data acquisition and evaluation – measuring, controlling, regulating

Mechanical implementation – multiple test stand

Test stand construction version

Standard test sequence for sealing systems

Individual seal test stand

© Hänchen 2017

Why Hänchen as a manufacturer for servohydraulic test machines?

Benefit from many years of experience with test stand technology

Many years of internal product development, research and development of test stands, test fields and complex test machines laid the foundation for modern Hänchen test stand construction. Our well-known high quality standards for all Hänchen products gave this development a massive boost. Today, Hänchen has developed into a reliable partner for individual test stands and test machines. Each EoL test stand is custom-made to customer specifications. Hänchen test stands are individually developed custom machines with a consistent concept. With every test stand project, you as the customer have a central contact person. This allows individual and energy-efficient test fields and complex test machines to be seamlessly integrated into your own systems through customer-defined interfaces.

Our competence as a manufacturer of test stands and test machines

- More than half a century of hydraulic and seal competence

- Extensive experience in special machine construction of hydraulic and electrical special machines

- Experience in the systematised, individual design and realisation of customer projects

- Measurement, control and regulation technology, real-time control, measured value acquisition, sensor technology, fieldbus connection and evaluation

- Development of proprietary modular software, including graphical interface for control and regulation as well as communication at process level

- Comprehensive safety concepts up to PLe in accordance with the Machinery Directive, CE conformity, safety software

- Countless projects in the field of test stand construction and the development of complex test machines