Hydraulic cylinders for maritime applications

Shipbuilding: yachts, naval ships, submarines

Hydraulic cylinders for yachts and naval vessels are used, among other things, for rudder adjustment or for moving stern and side ramps, as hydraulic cylinders for davit systems and much more.

Depending on the application, hydraulic cylinders for maritime applications must be approved by the respective ship classification society. Hänchen designs such as rudder adjusting cylinders, flap cylinders, locking cylinders and special cylinders for control or actuation not only meet these requirements, approvals according to DNV-GL and LR can also be carried out directly in our company.

The following applies to all our hydraulic cylinders: Hänchen stands for individual designs, excellent quality and the best availability.

- We can react quickly: with 100% Made in Germany and 80% vertical integration.

- We offer spare parts and service worldwide, fly to the site and carry out maintenance work.

Areas of application of hydraulic cylinders in shipbuilding

Hänchen has been supplying hydraulic cylinders to a wide range of industries since 1952. We use this broad know-how in the further development of our standard range, as well as in the development of custom cylinders. Because special applications require tailor-made solutions.

Hydraulic cylinders for operational safety and control

Rudder adjustment cylinder & control cylinder

Rudder blades are controlled by hydraulic rudder adjusting cylinders in single-rod and double-rod construction. For maximum manoeuvrability of the ships, low-friction and high-precision positioning of these hydraulic cylinders is particularly important.

Flap cylinders for adjusting doors and flaps

Hydraulic flap cylinders are used in shipbuilding to operate doors, gates and hatches. These actuators can be equipped with integrated interlocks that securely lock the piston rods in the event of pressure drop. Short installation lengths and individual designs are particularly important here.

Flap cylinders for tailgate adjustment

Ferries and naval ships are sometimes loaded and unloaded via the tailgate. Tailgate cylinders with a watertight ball joint are used to adjust this flap.

Hydraulic cylinders for deck structures

Hydraulic cylinders for davit systems

A davit is a launching device for tender and rescue boats from ships as well as for swimming platforms or jet skis. The cranes - some of which are pivoting - are mounted on the side near the side wall or on the stern and moved via hydraulic cylinders.

Hydraulic cylinders for ship access systems

Entering and leaving a ship is via stern and side gangways or yacht ladders. These are extended and retracted by hydraulic cylinders.

Hydraulic cylinders for adjustable floor control

Adjustable floors are used on yachts in the pool area. They allow you to individually adjust the pool depth or completely close the pool to use the area as a party deck. Hydraulic cylinders below the pool floor move a scissor lift system. They are always surrounded by pool water (fresh or salt water) and are operated exclusively with water hydraulics.

Technical properties

Hydraulic cylinders for yachts and naval vessels

when used for maritime applications.

- Materials: Stainless steel, DUPLEX steel, Niro

- Certification: DNV-GL and other acceptance regulations

- Material certificates

- Corrosion protection for seawater resistance

- Integrated position transducer

- Incl. lowering brake and load holding valve

- Hydraulic pressure: up to 320 bar

- Dimensions: bore up to 300 mm, stroke up to 6,000 mm

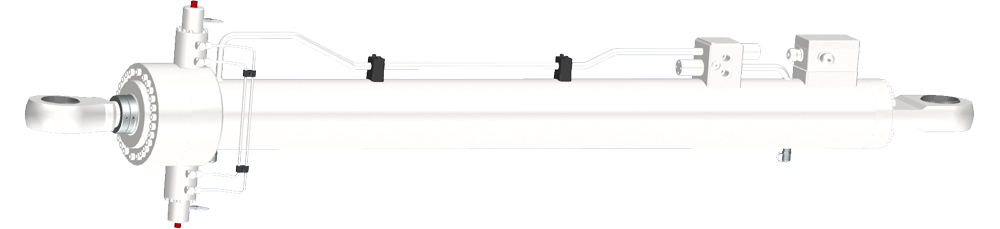

Design cylinder specially for yachts

Super, luxury and mega yachts are built as unique pieces individually according to the ideas of their owners. Design hydraulic cylinders, which are installed in the visible area, have special aesthetic requirements in addition to their functionality. We meet these special design requirements:

- Paint coating as desired, white RAL 9003

- Concealment of weld seams

- Stainless steel glass bead blasted

- Stainless steel polished to the highest yacht standard

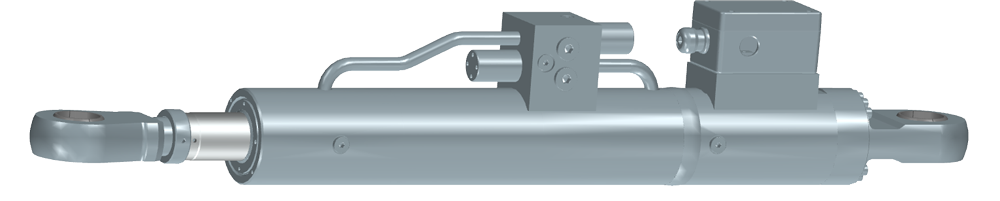

Special marine hydraulic cylinders

Grey ships are needed for reconnaissance, surveillance, deterrence and protection. Here, hydraulic cylinders are often custom-made for the respective application. The small and compact design of the Hänchen cylinders is advantageous here. Further requirements for marine hydraulic cylinders are, for example:

- Paint coating as desired, grey RAL 7000

- Anodized piston rods for camouflage

- Low noise including peripheral components

- External pressure resistant for deep-sea applications up to 160 bar and more

- Free-moving, shock-resistant, stainless steel design

Locking

Options for piston fixation

For handling or safety reasons, clamping of the rod may be necessary. Hänchen offers two different technical solutions that can be individually adapted to your requirements.

1. Locking cylinder

This is an interlock integrated in the hydraulic cylinder. This can be achieved by means of jaws introduced radially to the cylinder axis, which lock the end position of the cylinder when the piston rod is extended. The locking and unlocking is active-hydraulic.

2. Element clamping unit

The hydraulically releasable clamping unit Ratio-Clamp® is a separate product that can be flanged directly to the hydraulic cylinder or installed parallel to it. The clamping unit can serve as a safety element, as it locks the piston rod in the event of pressure drop - at any point. Learn more about the clamping unit as a locking element here.