Mounting elements

Individual quantities and small series

Precise mounting elements have been manufactured at Hänchen since the beginning of hydraulic cylinder design in 1925. Many individual solutions have always been realised - exactly what you need to fit your application.

For forces from 1 kN to 6,000 kN. Whether according to DIN, ISO or your own standard – we produce according to your engineering drawing or take over the entire engineering for you, including consulting.

- Implementation of your requirement

- Large component diameters, up to 200 mm

- Individual items and small series

- Made in Germany

Mounting elements and clevis brackets

Pivoted mounting elements

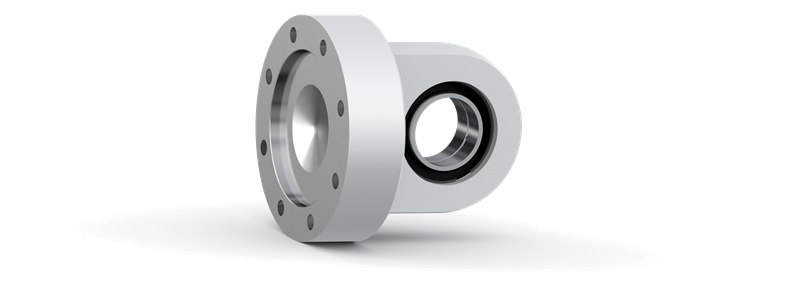

Mounting flanges

Spherical bearing flanges

Application examples of mounting elements

|

Bearing housing block for hydrostatic guide pillars Manufacturing steps: milled, surface ground and surface burnished Material: Steel, length 400 mm, width 200 mm and height 600 mm, bore diameter 200 mm |

|

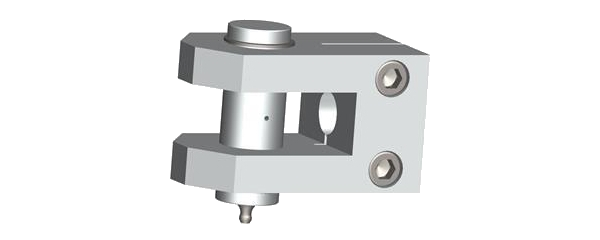

Test specimen holder Manufacturing steps: Drilling and milling as well as phosphating of the surface Material: S355, length 505 mm, width 60 mm and height 320 mm |

|

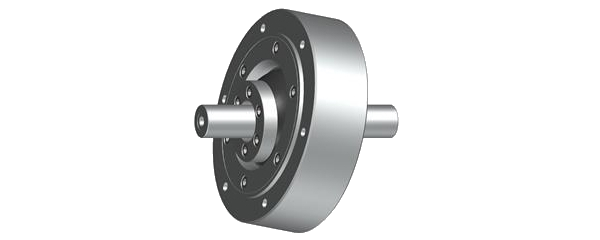

Bearing housing Manufacturing steps: Drilling and milling as well as phosphating of the surface Material: S355, length 320 mm, width 60 mm and height 505 mm |

|

Bearing housing or bearing support Manufacturing steps: Drilling and milling as well as phosphating of the surface Material: S355, length 320 mm, width 60 mm and height 245 mm |