Blade pitch adjustment in wind turbines

Industrial hydraulic cylinders

For 10 years, Hänchen hydraulic cylinders, as offshore-suitable technology, have been controlling blade pitch adjustment in REpower wind turbines.

"For our wind turbines, only a failure rate of 0 is acceptable. The supplied parts make a decisive contribution to this quality," emphasises Dipl.-Ing. Hauke Petersen from technical support at REpower in Husum. "This will apply to an even greater extent in the future due to the offshore plants. Because every failure at sea can necessitate a helicopter deployment.

- Extremely long service life

- In trouble-free operation for 12 years

- Over 90,000 operating hours

- Micro-movements as well as continuous paths

Technical requirements for the hydraulic cylinder

- Use of high-quality components

- Temperatures down to -15 °C, humid and salty air

- Stroke 380 mm, Pressure 160 bar

- Positioning accuracy up to 0.1 degrees

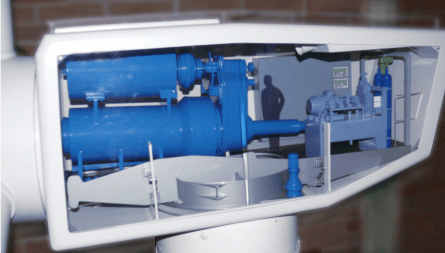

Hänchen hydraulic cylinders from Ostfildern near Stuttgart are reliable components. They have proven themselves under the aforementioned stringent conditions for over 12 years in the plants of the world's seventh-largest wind energy company. The Hamburg-based company has developed wind turbines that can produce five megawatts and more. It is currently building the most powerful offshore wind generators in the world.

The product range of the "windmill" manufacturer now includes plants that achieve rated outputs of 1,500 to 5,000 kilowatts. REpower relies on the highest quality, reliability, technological expertise and attention to detail and expects the same from its partners and suppliers. When selecting suppliers, priority is therefore given to the high quality of the components. This is the only way to develop and produce multi-megawatt plants. REpower has so far built 1,600 of these generators on land. However, the two plants installed at sea place particularly high demands: These particularly low-maintenance plants are also ideally suited for use on the high seas.

For 12 years, Hänchen hydraulic cylinders have been used in 90 wind turbines, which REpower took over from the Husumer Schiffswerft HSW, for blade pitch adjustment without any failures. Due to their stability over 90,000 operating hours, they offer extremely high reliability.

REpower is currently working with electromechanical blade pitch adjustments in wind turbines. This is due to the company's safety philosophy: In order to bring the rotor to a standstill in an emergency under all circumstances, three independently operating blade adjustment mechanisms are absolutely necessary for a design without a service brake. The plants of HSW equipped with the Hänchen cylinders pursue a different safety philosophy. In their case, the brake and adjustment mechanism are separate: "We are currently choosing the brake-less design," explains Petersen, who has also written a children's book about the construction of wind turbines. "The hydraulic cylinders from Hänchen do not have to hide from the electrical drives in any way, especially when it comes to performance and reliability."

REpower took over the technology for hydraulic blade pitch adjustment from the Husumer Schiffswerft. And the main argument for the continued use of the cylinders from Hänchen Hydraulik from Ostfildern was the high reliability. In the 12 years that the 90 wind turbines have been in operation, there have been no failure-related downtimes. "The hydraulic cylinders from Hänchen are guaranteed not to be among our problems. This is already proven by the fact that we have not stored any spare parts for them," emphasises Dipl.-Ing. Oliver Blum, who works in support together with Petersen. "Because the failure rate for electromechanical technologies is somewhat higher due to the technology."

The Hänchen cylinders, listed as custom cylinders because of a special piston rod thread, move three rotor blades simultaneously around their longitudinal axis by means of a push rod. They form the rotor with a diameter of 57 m. The adjustment mechanism works similarly to a modern ship propeller. The hydraulic cylinder must position the blades with a precision of up to 0.1 degrees. This is the only way to achieve the angularly accurate positioning of the blades specified by the design. The push rods of the cylinders cover both micro-movements and continuous paths. Depending on the wind speed, the operating point is approached, which ensures a constant speed of the generator. The control mode is decisive here. Because constant minimal movements are associated with high loads for the operation of the plant. These micro-movements in particular are a challenge for mechanics, electromechanics and hydraulics alike: It must be ensured that lubrication is guaranteed even with continuous minute movements in a sector of 0.5 mm.

In addition, there are the extreme environmental conditions: The plant must work just as precisely at an air temperature of -15° C as at +45° C, and humidity and salty air must not cause any problems. Here, Hänchen can draw on experience in the use of high-performance cylinders, such as those used in blast furnaces in a hydrofluoric acid-containing atmosphere to move moulds with up to 35 t of glowing steel at several Hz in 24-hour operation.

The challenge lies in the optimal control. The plant tries to maintain a certain speed and thus power. Depending on the wind strength, the concept provides for two power levels. These power points are at 1,000 or 1,500 revolutions at the generator, which are supplied by the rotor via a gearbox. They should be approached as constantly as possible in order to avoid fluctuations in the power grid. The blade adjustment must therefore ensure that the blades are taken out of the wind even in gusty air as the wind increases, so that the speed remains constant at 23 rotor revolutions per minute.

The hydraulic cylinder works here with an integrated position transducer. Hänchen supplies the complete unit for this purpose, which forms a particularly exact, compact and reliable small system. It works with a stroke of 380 mm and requires a pressure of 160 bar. For safety reasons, the hydraulic power unit works with an accumulator: This provides a pressure reserve even in the event of a failure of the power unit in order to immediately take the blades out of the wind in the event of problems. Thus, the hydraulic cylinders not only guarantee precision, load capacity and reliability. They also prove their suitability for safety-relevant tasks. Especially under the aggravated conditions of offshore wind power, the hydraulic specialists from the Stuttgart region expect a significant expansion of this market segment.

© Hänchen 2008

Press article on the application of hydraulic cylinders for blade pitch adjustment

|

Optimal use of the wind - Hydraulic cylinders as offshore-suitable technology |