Clamping unit for sensitive applications

Rod locking with sealing system pressure piston seal

For highly sensitive applications, we recommend the rod locking version with a pressure piston seal, where no pressurized seal touches the rod. This makes the sliding friction extremely low and constant, regardless of the releasing pressure.

The clamping unit with pressure piston seal is intended for test applications and other highly dynamic applications, as well as for precision tasks. This is especially true in conjunction with cylinders with non-contact seals.

Herbert Hänchen GmbH

- For particularly sensitive applications

- Low sliding friction

- Speeds of up to 2 m/s possible

- Pressure-independent sliding friction

Functional principle of the clamping unit with pressure piston seal

Ratio-Clamp® rod locking with pressure piston seal

The pressurized seals on the clamping sleeve and locking piston have been replaced by a pressure piston seal that does not touch the rod. As a result, the extremely low sliding friction is independent of the releasing pressure and remains constant.

Technical data of the rod locking with pressure piston seal

Since the clamping geometry and spring are identical to the standard Ratio-Clamp®, the same holding loads can be achieved. However, due to the smaller hydraulic working area, the minimum permissible releasing pressure increases. The maximum releasing pressure remains at 160 bar.

- For all round rods with a hard surface

- Loadable regardless of direction

- After 2 million switching cycles, a factory inspection of the Ratio-Clamp® is necessary.

- Max. rod speed: 1 m/s with Servocop®, 2 m/s with pressure piston seal

- Max. releasing pressure: 160 bar

- Working temperature: -30°C to +80°C

- Fluids: Mineral oils, others such as water, HFC or Skydrol® upon request

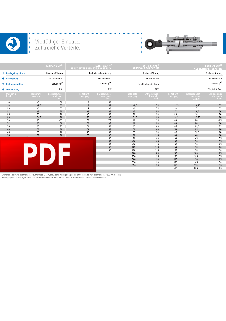

| RATIO-CLAMP® |

RATIO-CLAMP® PRESSURE PISTON SEAL |

|||||

| + Releasing pressure + Locking + Sealing system + Certification |

Basic design With spring force Servocop® TÜV |

Basic design With spring force Pressure piston seal TÜV |

||||

| Rod-Ø (mm) |

Holding load max. (kN) |

Releasing pressure min. (bar) |

Holding load max. (kN) |

Releasing pressure min. (bar) |

||

| 16 | 10 | 60 | ||||

| 18 | 12,5 | 55 | 12,5 | 75 | ||

| 20 | 14 | 55 | 14 | 75 | ||

| 22 | 17 | 70 | 17 | 90 | ||

| 25 | 20 | 70 | 20 | 90 | ||

| 28 | 31,5 | 90 | 31,5 | 120 | ||

| 30 | 40 | 105 | 40 | 135 | ||

| 32 | 40 | 60 | 40 | 90 | ||

| 36 | 45 | 75 | 45 | 100 | ||

| 40 | 50 | 80 | 50 | 100 | ||

| 45 | 65 | 70 | 65 | 90 | ||

| 50 | 80 | 90 | 80 | 110 | ||

| 56 | 90 | 75 | 90 | 100 | ||

| 60 | 100 | 75 | 100 | 100 | ||

| 63 | 100 | 85 | 100 | 110 | ||

| 70 | 140 | 80 | 140 | 110 | ||

| 80 | 180 | 90 | 180 | 110 | ||

| 90 | 200 | 65 | 200 | 85 | ||

| 100 | 250 | 75 | 250 | 95 | ||

| 110 | 300 | 65 | 300 | 90 | ||

| 120 | 330 | 70 | 330 | 90 | ||

| 125 | 350 | 75 | 350 | 90 | ||

| 140 | 450 | 65 | ||||

| 160 | 750 | 90 | ||||

Further holding loads & rod Ø on request.

A hydraulic locking mechanism is possible up to 2,000 kN holding load and rod Ø 300 mm.

The values given apply to operation with mineral oil. The holding load may differ when using other fluids.