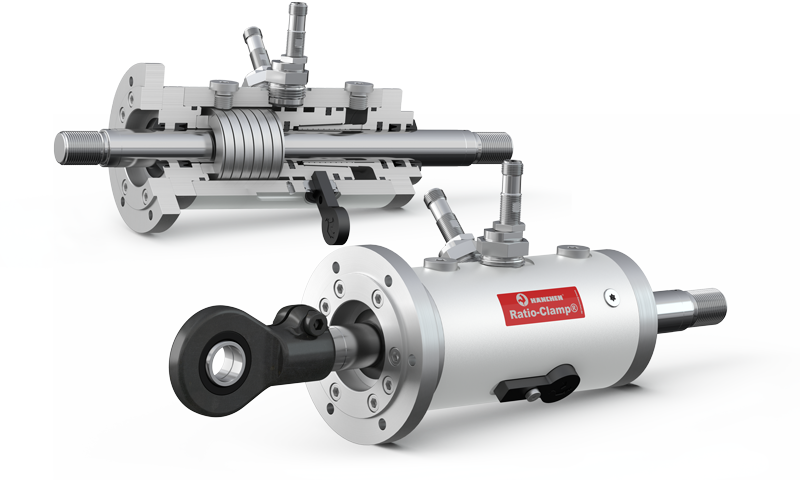

Locking unit Ratio-Clamp®

A clamping unit for rod locking

The patented locking unit Ratio-Clamp® fixes round rods without energy supply for an unlimited time.

The clamping unit is used worldwide as a safety component in personal and plant protection, as a holding element for tools and workpieces, and as rod locking in production processes or testing procedures.

Advantages of the locking units:

- Can be used horizontally and vertically

- Direction-independent, can be loaded in tension and compression

- Clamping force acts immediately, without further movement of the rod

- Releasing the clamping by hydraulic pressure, without return movement of the rod

- Holding load up to 2,000 kN

- Proven product at Hänchen since 1965

- Positionally accurate locking

- Securely holding raised loads

- Round rods up to Ø 300 mm

- 100% made in Germany

Application areas of locking units

Efficient rod lockings

There are many situations in which rods must be held in a specific position: Here are a few practical examples where our rod locking systems securely fix the axles.

- Grinding machine > Production

During the production of ICE railway sleepers, extremely large and heavy concrete workpieces must be positioned precisely and safely for grinding to an accuracy of 0.01 mm. The hydraulic cylinders and Ratio-Clamp® clamping units are designed precisely for these requirements.

- Aviation > Test engineering

The structures for aircraft tests are sophisticated down to the last detail. Hänchen test actuators are used in various test areas to simulate environmental conditions and loads during the individual flight phases. To protect the elaborately manufactured and expensive systems, Ratio-Clamp® rod lockings are used.

- Presses > Production

Locking cylinders from Hänchen guarantee safe movement of the press. Clamping units ensure safety during the pressing process in compression and injection moulding presses for the production of moulded parts made of synthetic materials and rubber in accordance with EN 289.

- Railway technology > Maintenance

For maintenance purposes, trains must be fixed in the raised position - the Ratio-Clamp® is ideally suited for this. The locking units hold the train securely in position until the work is completed and it can return to the rails.

- Profiling machine > Production

In the production of metal profiles, Hänchen locking units guarantee precise machining and consistent quality. During the production process, they secure the machining of the profiles by locking the shaping tools. Ecologically sound and efficient, purely with spring force.

The locking unit in detail

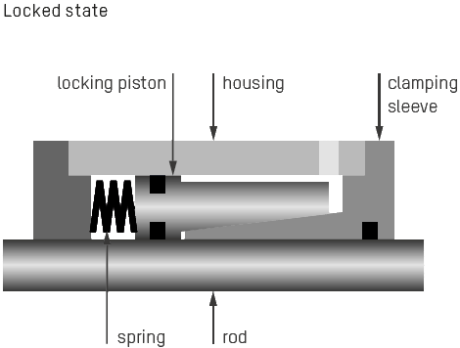

The Ratio-Clamp® locking unit works mechanically according to the functional principle of frictional contact. The force stored in disc springs is deflected via cones and clamps the rod by means of friction.

- Locking and securing the load

If the releasing pressure drops, the force stored in the springs is released and causes the rod to be clamped. This secures the load and the Ratio-Clamp® clamping unit is ready to take over the load.

- Load

Loading is possible immediately after clamping. No axial movement of the rod is required. In the clamped state, the forces can be kept free of play in both directions.

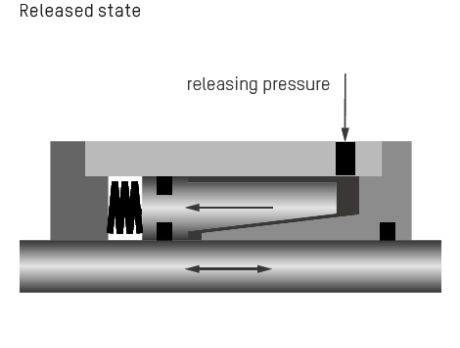

- Release

The locking piston is moved against the spring force by hydraulic releasing pressure and releases the clamping of the locking unit.The rod can be moved in both directions.

- Overload

A brief overload with slippage of the rod is possible without damaging it or the clamping unit.

The video shows the functional principle of the clamping unit Ratio-Clamp® using the example of a gantry milling machine.

These locking units from Hänchen can be used both for exact locking and for securing against unwanted movements.

- Fixing round rods of all types, in any position

- Clamps from standstill, also for braking from movement in the event of an occasional accident

- Clamping force without energy supply for an unlimited time

- In the event of (un)controlled pressure drop, emergency shutdown, power failure or system damage

- Fixes axles precisely, even when external forces act on the rod

Energy efficiency and precision for all cases

Locking unit Ratio-Clamp®

Do you have an application where a round rod needs to be held in a defined position? There are several ways to achieve this: by electronic control, shutting off all ports, locking with pivot pins, or by using locking units.

The clamping unit Ratio-Clamp® scores with numerous advantages.

- Stepless clamping without energy supply

- Fixes exactly in any position

- Holds position with temperature fluctuations

- Saving of energy costs by clamping with spring force

Comparison of fixing options for round rods

| Electronic control |

Shut off ports |

Pivot pin locking |

Clamping unit Ratio-Clamp® |

|

| Energy efficiency | – | + | + | + |

| Positional accuracy | + | – | + | + |

| Independence from external influences |

+ | – | + | + |

| Effort | – | + | – | + |

| Flexible positioning | + | + | – | + |

Advantage of the Ratio-Clamp® locking unit: It holds the piston rod in any position without hydraulic or electrical energy supply.

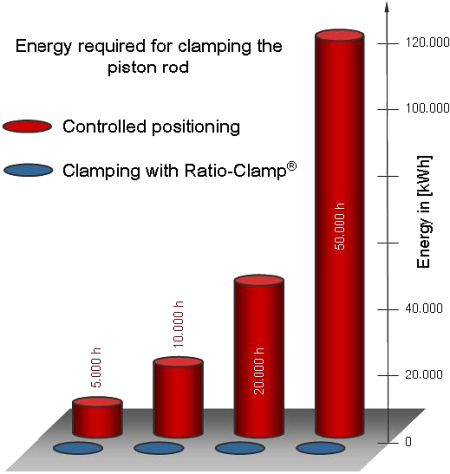

Case study: Energy consumption for holding a piston rod

A hydraulic cylinder with a bore of 80 mm is moved at 150 bar with a speed of 0.5 m/s. The required drive power is 38 kW.

With electronic control using a controlled pump, there is a power loss of approx. 1.25 kW from the controlled pump. In addition, losses at the control valve of approx. 1.25 kW are to be expected. In this example, the total power loss of the controlled drive is 2.5 kW. With a holding time of 5,000 hours per year, the energy loss is over 12,000 kWh.

With the locking unit Ratio-Clamp® , the energy loss is 0 kWh during the holding process.

ROD LOCKING FOR TEST APPLICATIONS

For very sensitive or highly dynamic applications, we recommend the sealing system "pressure piston seal". The sliding friction here is extremely low and independent of the releasing pressure. See description in the next section under "Sealing system"

Equipment

Features of a clamping unit

- Releasing pressure

Basic design

The basic releasing pressure required to release the clamping unit is between the minimum pressure and the maximum permissible pressure of 160 bar.

Reduced design

For applications with low supply pressure, the version with reduced releasing pressure can be selected.- Certification

TÜV type test

Each Ratio-Clamp locking unit® is type-tested by TÜV SÜD.

DGUV Test

This clamping unit carries the certificate of the DGUV Test (testing and certification system of the German Social Accident Insurance). For use as a safety component for the Ratio-Clamp® a B10D value according to EN ISO 13849-1 is available. The 2-fold safety required by the DGUV for the maximum holding load is already taken into account in the load specification in the technical data.

Learn more about the clamping unit Ratio-Clamp® with DGUV test certification

- Interlock

With spring force

Normally, the rod locking is achieved via the energy stored in springs. This allows the rod to be held for an unlimited time without energy supply.

Hydraulic

If very high holding loads are required, the clamping unit can also be locked hydraulically. It is released as usual using hydraulic pressure.- Sealing system

Servocop®: compact seal, lip seal, wiper ring

In the basic design, the Ratio-Clamp locking unit operates® with the friction-optimised sealing system Servocop®. In this system, the primary seal is in contact with the rod. The maximum rod speed is 1 m/s.

Pressure piston seal, lip seal, wiper ring

For very sensitive applications, we recommend the version with pressure piston seal, in which no pressurised seal touches the rod. As a result, the sliding friction is extremely low and constant regardless of the releasing pressure. The maximum rod speed is 2 m/s.

Quality thought further.

- Hydraulic cylinder

-

can be mounted on Hänchen industrial hydraulic cylinders or standard cylinders DIN/ISO according to ISO 6020-1, ISO 6020-2 and third-party products via a fixed flange. For this purpose, the piston rod must be extended according to the length of the clamping unit. For separate mounting, the clamping unit can also be loosely mounted with the aid of a collar flange to compensate for an axial offset.

- Proximity switch

-

The respective status – rod locked or released – can be queried via inductive proximity switches. When using the Ratio-Clamp® as a safety component or with required DGUV Test certification, the installation of a proximity switch with diagnostic output is mandatory. This also monitors the function of the switch and the supply line.

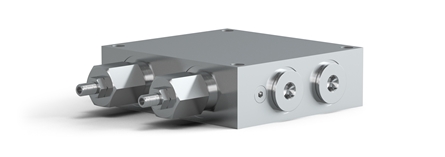

- Control block

-

A control block is used when the locking unit is mounted on a hydraulic cylinder. It ensures a consistent, functional control and reduces the complexity of the control system.

When controlling a Ratio-Clamp®, it must first be released by applying pressure to the releasing port, only then may the rod be moved. When using a clamping unit together with a hydraulic cylinder, this can be done by means of hydraulic sequence control or electronic monitoring. For example, sensors in an electronic control system can measure the load on vertically installed cylinders in order to build up a counter-pressure. This avoids jerking of the rod during releasing.

This can also be achieved with a hydraulic control block: First, the releasing pressure is built up, then the cylinder is pressurised. Suitable valves trap the pressure in the cylinder, so that the Ratio-Clamp® can be released almost jerk-free even with vertical loads.

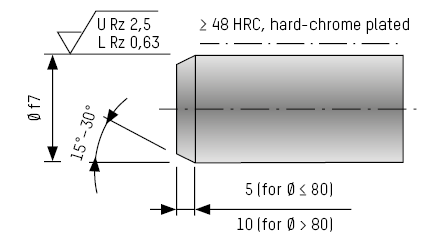

- Functional rod

-

The round rod to be clamped should have a hard surface and must meet the minimum requirements when installing the Ratio-Clamp®. A honed rod is recommended.

At Hänchen you can order a suitable functional rod directly and configure it via the HäKo product configurator.

Technical data of the locking unit

hydraulically released

- For all round rods with a hard surface

- Loadable regardless of direction

- Factory check of the Ratio-Clamp® required after 2 million switching cycles

- Max. rod speed: 1 m/s with Servocop®, 2 m/s with pressure piston seal

- Max. releasing pressure: 160 bar

- Working temperature: -30 °C to +80 °C

- Fluids: Mineral oils or HFC*, others such as water or Skydrol® on request

| RATIO-CLAMP® |

RATIO-CLAMP® REDUCED RELEASING PRESSURE |

RATIO-CLAMP® PRESSURE PISTON SEAL |

||||||

| + Releasing pressure + Locking + Sealing system + Certification |

Basic design With spring force Servocop® TÜV |

Reduced design With spring force Servocop® TÜV |

Basic design With spring force Pressure piston seal TÜV |

|||||

| Rod-Ø (mm) |

Holding load max. (kN) |

Releasing pressure min. (bar) |

Holding load max. (kN) |

Releasing pressure min. (bar) |

Holding load max. (kN) |

Releasing pressure min. (bar) |

||

| 16 | 10 | 60 | 8 | 50 | ||||

| 18 | 12,5 | 55 | 8 | 35 | 12,5 | 75 | ||

| 20 | 14 | 55 | 9 | 40 | 14 | 75 | ||

| 22 | 17 | 70 | 12 | 45 | 17 | 90 | ||

| 25 | 20 | 70 | 15 | 50 | 20 | 90 | ||

| 28 | 31,5 | 90 | 25 | 65 | 31,5 | 120 | ||

| 30 | 40 | 105 | 30 | 75 | 40 | 135 | ||

| 32 | 40 | 60 | 30 | 45 | 40 | 90 | ||

| 36 | 45 | 75 | 32 | 50 | 45 | 100 | ||

| 40 | 50 | 80 | 38 | 55 | 50 | 100 | ||

| 45 | 65 | 70 | 45 | 50 | 65 | 90 | ||

| 50 | 80 | 90 | 55 | 60 | 80 | 110 | ||

| 56 | 90 | 75 | 60 | 50 | 90 | 100 | ||

| 60 | 100 | 75 | 70 | 55 | 100 | 100 | ||

| 63 | 100 | 85 | 60 | 55 | 100 | 110 | ||

| 70 | 140 | 80 | 100 | 55 | 140 | 110 | ||

| 80 | 180 | 90 | 130 | 65 | 180 | 110 | ||

| 90 | 200 | 65 | 200 | 85 | ||||

| 100 | 250 | 75 | 250 | 95 | ||||

| 110 | 300 | 65 | 300 | 90 | ||||

| 120 | 330 | 70 | 330 | 90 | ||||

| 125 | 350 | 75 | 350 | 90 | ||||

| 140 | 450 | 65 | ||||||

| 160 | 750 | 90 | ||||||

Further holding loads & rod Ø on request.

A hydraulic locking mechanism is possible up to 2,000 kN holding load and rod Ø 300 mm.

*The specified values apply to operation with mineral oil. When using other fluids such as HFC, the holding load may differ.

FAQ - Clamping unit Locking unit

How can I clamp a hydraulic cylinder?

Hydraulic cylinders can be designed as clamping or locking cylinders, i.e. a clamping system is structurally integrated. Alternatively, hydraulic clamping can be attached to the head of the cylinder via a flange, which clamps the piston rod as soon as the hydraulic pressure drops to 0 bar.

What options are there for a load holding function?

A load holding function can be implemented in various ways. Loads can be held by:

- hydraulically shut off ⇒ non-return valve or lowering brake valve

- mechanically lock ⇒ pivot pin or toothing

- electronically controlled ⇒ hold in position in the control circuit

- Clamping element like the Ratio-Clamp® locking unit ⇒ clamp rod by frictional contact

Why is my axis sinking despite the load control valve?

The positional accuracy of the hydraulic cylinder closed with a lowering brake valve depends on the oil compressibility, temperature influences and the leakage at piston and rod seals. If it is to be prevented under all circumstances that the axis lowers/sinks despite lowering brake valve, a mechanical locking unit can be used instead. This functions via frictional contact and thus holds the exact position independently of time and external conditions.

Why doesn't my lowering brake valve hold the piston rod?

In principle, the piston rods of a cylinder can be held in place by means of a lowering brake valve. It should be noted that unwanted lowering/sinking can occur due to leakages at the seals or temperature fluctuations, which depend on the viscosity of the oil. A more reliable holding element with a high holding load is a locking unit such as the Ratio-Clamp®.

What is a locking unit?

A locking unit is an element that clamps round rods via spring force. In most cases, it works in such a way that the clamping is held open by pneumatic or hydraulic pressure. In the event of a pressure drop, the rod is clamped within a few milliseconds via frictional contact. The holding load of the locking unit is stable for an unlimited period of time. It can be used, for example, as a safety element in the event of a power failure or when the power is switched off to save energy.

Are there locking units for higher forces?

Locking units can be operated pneumatically or hydraulically. Pneumatic locking units are available on the market up to a maximum of 40 kN. Hydraulic locking units are suitable for higher forces, these go up to 750 kN and more.