Control block

Control of the Ratio-Clamp® clamping unit

When controlling a Ratio-Clamp®, it must first be released by applying pressure to the releasing port, only then may the rod be moved.

When using a clamping unit together with a hydraulic cylinder, this can be done by means of a hydraulic sequence control:

First, the releasing pressure is built up, then the cylinder is pressurised. Suitable valves clamp the pressure in the cylinder so that the Ratio-Clamp® can be released almost without jerking, even with vertical loads.

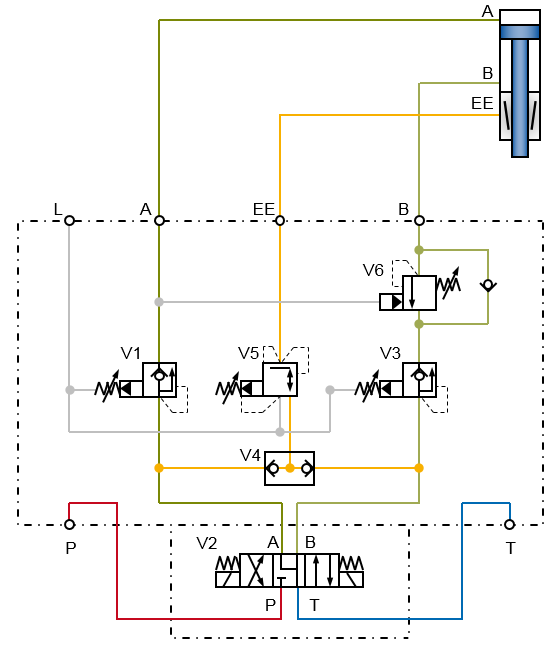

Installed between directional valve V2, clamping unit and hydraulic cylinder, the control block ensures a logical and functional control and thus reduces the circuitry effort for the user to a minimum.

Control block basic design: suitable for a horizontal mounting position of the clamping unit, use up to 160 bar.

Control block universal design: suitable for a horizontal and vertical mounting position of the clamping unit, use up to 300 bar.

Integrated functions

Sequential workflow

When using a Ratio-Clamp® clamping unit together with a hydraulic cylinder, the clamping unit must first be released by applying pressure to the releasing port EE, only then may the rod be moved by applying pressure to the working areas of the cylinder via the connection lines A or B.

If the pressure in the connection lines A or B to the hydraulic cylinder drops, for example due to the switching of a directional valve after reaching a certain position, the pressure in the releasing port EE also drops and the Ratio-Clamp® clamping unit is locked again.

This process takes place automatically in both the basic and universal versions when using the control block. The shuttle valve V4 controls the releasing pressure of the clamping unit and only when the pressure has built up here, the respective pressure sequence valves V1 or V3 apply pressure to the corresponding chambers of the cylinder.

Load-holding

With vertical installation, the load on the cylinder is transferred from the clamping unit. The load is secured.

In the cylinder chamber at port B, the holding pressure corresponding to the load is trapped by the load-holding valve V6.

When restarting after clamping, i.e. when releasing, this holding pressure takes over the load until the opening pressure of the valve is reached and the cylinder extends. This enables an almost jerk-free restart.

This function is only implemented in the universal version.

Pressure reduction

In the universal 300 bar version, the pressure reducing valve V5 limits the releasing pressure to 160 bar. This is the maximum permissible releasing pressure of a Ratio-Clamp® clamping unit.

This function is particularly necessary if the cylinder is to be operated at a higher pressure.

Please note that the clamping unit may only be loaded up to the maximum permissible holding load.

This function is only implemented in the universal version.

| A |

Extend port | V1, V3 | Pressure sequence valves |

| B | Retraction port | V2 | Directional valve |

| EE | Releasing port | V4 | Shuttle valve |

| L | Leak oil port | V5 | Pressure reducing valve pmax = 160 bar |

| P, T | Port pressure, tank | V6 | Load holding valve |

When using the clamping unit without a cylinder, it must also be ensured that the clamping unit is completely released before the rod moves.

When used for a high performance level, the load holding valve V6 can also be designed with feedback.

Technical Data

Maximum pressure pmax = 300 bar

Flow rate Vmax = 45 l/min

Oil temperature -20 °C to 80 °C

Seals made of NBR

Mineral oil VG 20 to 68 HLP, HLPD according to DIN 51524, cleanliness 19/17/14 according to ISO 4406