Industrial hydraulic cylinder from Hänchen

Hydraulic cylinder manufacturer

Hydraulic cylinders offer many advantages: they are long-lasting, low-friction and robust. The 120 and 300 series from us as a hydraulic cylinder manufacturer have top response behavior, low wear and therefore long maintenance intervals.

In typical Hänchen quality with matched sealing elements, these industrial hydraulic cylinders meet the highest technical requirements for safe and reliably controlled drives.

In addition to our standard modules, we develop and produce high-quality custom hydraulic cylinders for a wide range of applications.

- Start-up from standstill under full load

- Continuous & simultaneously accessible power

- Compact construction

- Low friction

- No risk of failure

- No stick-slip effect

Properties of an industrial hydraulic cylinder

Advantages of hydraulics

- Ready to go: from standstill under full load

- The compact design with low inertial resistance guarantees a high power density. This allows the cylinders to start up immediately under full load and quickly change the direction of movement.

- In position: in every situation

Speeds are steplessly adjustable while maintaining a simple control concept with high positional accuracy, even when requirements vary greatly.

- Fast: even under high loads

The force and speed are constant and simultaneously accessible at full power.

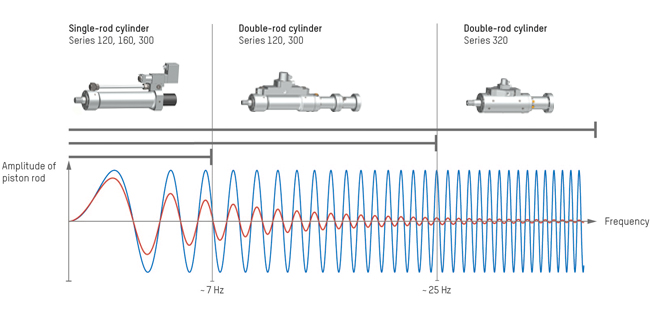

- Hydraulic cylinders for every frequency range

The required dynamics of the drive determine the type of effect of the cylinder. With fast control valves, even single-rod cylinders achieve a high profile quality at high frequencies. The limit values shown in the diagram are intended as guidelines for your design. They depend on various operating conditions - we will help you with the selection.

Hänchen industrial hydraulic cylinder series

For long and short stroke oscillations

Our extensive standard range is perfectly suited for many different applications.

If a higher batch size is required repeatedly, it is worth designing the hydraulic cylinder precisely to the respective requirement. As a hydraulic cylinder manufacturer, Hänchen takes a holistic approach here in order to offer a series cylinder with an optimised price-performance ratio.

- Low cylinder unit costs

- Cylinder can do exactly what the application requires

- Fast delivery times thanks to processes optimised for serial production

- Rapid supply of spare parts by keeping the seals in stock

If you require double-acting cylinders as standard cylinders, please contact us directly.

Equipment industrial hydraulic cylinder

Sealing and guiding systems

The sealing system in the cover and on the piston is the core component of a hydraulic cylinder and determines its application possibilities. This defines the friction characteristics and stick-slip behaviour of the industrial hydraulic cylinder, the achievable speeds and the effects of side loads.

Here you can find out more about the equipment of cover and piston in the hydraulic cylinder.

Accessories and tools for industrial hydraulic cylinders

Mounting elements, assembly tools and tools

You can find our standard accessories and tools in the HÄKO product configurator to match your selected cylinder.

Technical data of the Hänchen industrial hydraulic cylinder

Hydraulic cylinder from the manufacturer

Type of effect: single-rod cylinder, double-rod cylinder | Sealing systems: Basic design, Servocop®, Servoseal®, Servofloat® |

Speeds: up to 2 m/s | Stroke : 1 - 6,000 mm

The hydraulic calculation of hydraulic cylinders, as well as the selection of suitable accessories, valves and data sheets can be carried out in our product configurator HÄKO.

| Series 120 | Series 300 | |||||

| Bore (mm) |

Rod Ø (mm) |

Force F1 | F2 (kN) |

Max. pressure * (bar) |

Force F1 | F2 (kN) |

Max. pressure * (bar) |

|

| 25 | 12 16 |

7.4 | 5.7 7.4 | 4.3 |

150 150 |

--- 14.7 | 8.7 |

--- 300 |

|

| 32 | 16 20 |

12.1 | 9.0 12.1 | 7.4 |

150 150 |

--- 24.1 | 14.7 |

--- 300 |

|

| 40 | 20 25 30 |

18.8 | 14.1 18.8 | 11.5 --- |

150 150 --- |

--- 37.7 | 23.0 37.7 | 16.5 |

--- 300 300 |

|

| 50 | 25 30 40 |

29.5 | 22.1 29.5 | 18.8 --- |

150 150 --- |

--- 58.9 | 37.7 58.9 | 21.2 |

--- 300 300 |

|

| 60 | 30 40 50 |

42.4 | 31.8 42.4 | 23.6 --- |

150 150 --- |

--- 84.8 | 47.1 84.8 | 25.9 |

--- 300 300 |

|

| 80 | 40 50 60 |

75.4 | 56.5 75.4 | 45.9 --- |

150 150 --- |

--- 150.8 | 91.9 150.8 | 66.0 |

--- 300 300 |

|

| 100 | 50 60 80 |

117.8 | 88.4 117.8 | 75.4 --- |

150 150 --- |

--- 235.6 | 150.8 235.6 | 84.8 |

--- 300 300 |

|

| 125 | 60 80 100 |

184.1 | 141.7 184.1 | 108.7 --- |

150 150 --- |

--- 368.2 | 217.4 368.2 | 132.5 |

--- 300 300 |

|

| 140 | 80 100 |

230.9 | 155.5 230.9 | 113.1 |

150 150 |

--- 461.8 | 226.2 |

--- 300 |

|

| 160 | 80 100 |

301.6 | 226.2 301.6 | 183.8 |

150 150 |

--- 603.2 | 367.6 |

--- 300 |

|

| 180 | 100 120 |

381.7 | 263.9 381.7 | 212.1 |

150 150 |

--- 763.4 | 424.1 |

--- 300 |

|

| 200 | 100 120 140 |

628.3 | 471.2 628.3 | 402.1 --- |

200 200 --- |

--- --- 942.5 | 480.7 |

--- --- 300 |

|

| 220 | 120 140 160 |

760.3 | 534.1 760.3 | 452.4 --- |

200 200 --- |

--- --- 1,140.0 | 537.2 |

--- --- 300 |

|

| 250 | 120 140 180 |

981.7 | 755.6 981.7 | 673.9 --- |

200 200 --- |

--- --- 1,472.0 | 709.2 |

--- --- 300 |

|

| 300 | 160 200 |

1,413.7 | 1,011.6 --- |

200 --- |

--- 2,120.6 | 1,178.2 |

--- 300 |

|

* When pivot mounting the pressure is limited to 120 bar.

F1 = force extending when extend the cylinder | F2 = force retracting when retraction the cylinder

With double-rod cylinders, retraction and extension corresponds to the value F2.