Standard hydraulic cylinder according to DIN and ISO

Hydraulic cylinders with mounting dimensions according to DIN ISO 6020/6022

Honed surfaces, geometric accuracy, long service life. Compliant with mounting dimensions and accessories according to applicable standards, these series convince through their inner Hänchen values.

In typical Hänchen quality with matched sealing elements, these hydraulic cylinders meet the highest technical requirements for safe and reliably controlled drives. The Hänchen standard cylinders comply with the mounting dimensions according to DIN ISO 6020/6022.

Hänchen develops and produces high-quality hydraulic cylinder for a wide range of requirements.

- Extremely long service life

- Mounting dimensions according to DIN and ISO

- Tools according to DIN ISO 8132

- Extremely long maintenance intervals

- Honed sliding surfaces

- High accuracy of the components

DIN / ISO standards for hydraulic cylinders

There are numerous standards for hydraulic cylinders: The dimensional standards are intended to guarantee interchangeability between manufacturers. The following standards apply to round cylinders: DIN ISO 6020-1, DIN ISO 6022 and the tools for standard hydraulic cylinders such as rod ends fall under DIN ISO 8132.

The dimensional standard therefore describes the mounting dimensions of standard cylinders, but not the quality or material of the hydraulic cylinder.

See also: https://www.iso.org

Tip: Always compare standard dimensions between manufacturers, as the standard allows large tolerances.

Standard hydraulic cylinder DIN/ISO series from Hänchen

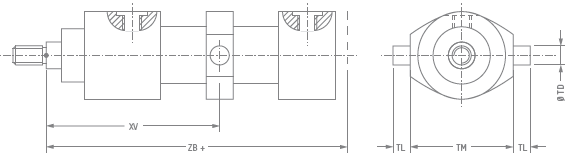

Standard hydraulic cylinder DIN/ISO with the same mounting dimensions in comparison:

left Hydraulic cylinder according to ISO 6022 with cushioning

right Hydraulic cylinder series 550 without cushioning

Accessories and tools for standard cylinder DIN/ISO

Mounting elements, assembly tools and tools

You can find our available standard accessories according to ISO 8132 / 8133 and other tools in the HÄKO product configurator to match your selected cylinder.

Technical data of the standard cylinder DIN/ISO

Type of effect: single-rod cylinder | Sealing systems: basic design, Servocop®, Servofloat® | Speeds: up to 0.5 m/s | Stroke: 1 - 6,000 mm

The hydraulic calculation of cylinders, as well as the selection of suitable accessories, valves and data sheets can be carried out in our product configurator HÄKO.

| Series 160 DIN ISO 6020-1 |

Series 550 DIN ISO 6022 |

||||

| Bore (mm) |

Rod Ø (mm) |

Force F1 | F2 (kN) |

Pressure max. (bar) |

Force F1 | F2 (kN) |

Pressure max. (bar) |

| 25 | 14 | 7.9 | 5.4 | 160 | --- | --- |

| 32 | 18 | 12.9 | 8.8 | 160 | --- | --- |

| 40 | 22 25 28 30 |

20.1 | 14.0 --- 20.1 | 10.3 --- |

160 --- 160 --- |

--- 31.4 | 19.1 --- 31.4 | 13.7 |

--- 250 --- 250 |

| 50 | 28 30 36 40 |

31.4 | 21.6 --- 31.4 | 15.1 --- |

160 --- 160 --- |

--- 49.1 | 31.4 --- 49.1 | 17.7 |

--- 250 --- 250 |

| 60 | 40 50 |

--- --- |

--- --- |

70.7 | 39.3 70.7 | 21.6 |

250 250 |

| 63 | 36 45 |

49.9 | 33.6 49.9 | 24.4 |

160 160 |

--- --- |

--- --- |

| 80 | 45 50 56 60 |

80.4 | 55.0 --- 80.4 | 41.0 --- |

160 --- 160 --- |

--- 125.7 | 76.6 --- 125.7 | 55.0 |

--- 250 --- 250 |

| 100 | 56 60 70 80 |

125.7 | 86.3 --- 125.7 | 64.1 --- |

160 --- 160 --- |

--- 196.3 | 125.7 --- 196.3 | 70.7 |

--- 250 --- 250 |

| 125 | 70 80 90 100 |

196.3 | 134.8 --- 196.3 | 94.6 --- |

160 --- 160 --- |

--- 306.8 | 181.1 --- 306.8 | 110.4 |

--- 250 --- 250 |

| 140 | 100 | --- | --- | 384.8 | 188.5 | 250 |

| 160 | 90 110 |

321.7 | 219.9 321.7 | 169.7 |

160 160 |

--- --- |

--- --- |

| 200 | 110 140 |

502.7 | 350.6 502.7 | 256.4 |

160 160 |

--- --- |

--- --- |

F1 = force extending when extend the cylinder | F2 = force retracting when retraction the cylinder