Venting set

Venting hydraulic cylinders

In addition to unpleasant operating characteristics such as jerky movements, air can also cause damage to the hydraulic cylinder and its sealing elements.

If hydraulic oil containing air bubbles is compressed very quickly, the bubbles are heated so much that the air-gas mixture can self-ignite. This creates a very high local pressure and temperature increase, which can also damage seals. This is called the diesel effect.

In addition, a cylinder filled only with air is not functional in the cushioning. Even a single extension at full operating speed can damage the cylinder.

Cylinders must be manually vented before start-up.

The venting process

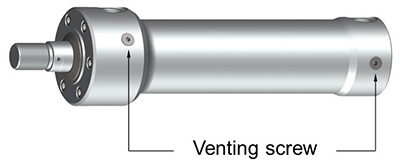

Venting of hydraulic cylinders is essential for their function. By repeatedly moving the cylinder over its entire stroke in both directions at the lowest possible pressure, the air is flushed out, the remaining air dissolves in the fluid and is conveyed into the tank. The venting screws are designed so that they only need to be loosened by one turn to allow the air to escape.

As a rule, hydraulic cylinders are supplied with special venting screws on both sides.

The venting holes are designed to be suitable for measuring couplings and for the use of a venting set. With the Hänchen venting set, a hydraulic cylinder can be vented cleanly and conveniently without additional tools and without leakage or dripping.

Venting set

If measuring couplings are installed in the venting ports of the hydraulic cylinder, the venting set can be connected directly.

The Hänchen venting set consists of

• Wide-neck bottle with air filter G1/8

• Measuring hose M16x2 for measuring coupling