Servoseal®

Sealing system cover

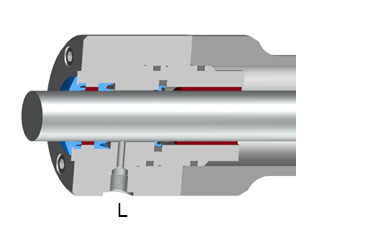

The sealing system in the cover Servoseal® is suitable for particularly low-friction and very sensitive movements. Extremely stick-slip-free movements can be achieved. Servoseal® is also suitable for highly dynamic movements and oscillations, as well as for loads on the cylinder with high side loads.

Function

An integrated retaining ring made of carbon reduces the contact pressure of the seal, which means that friction and wear are almost zero.

The sealing system Servoseal® operates virtually leakage-free. The small amount of leak oil is discharged into the tank at the functional oil port L.

The contacting (functional oil) seal and the wiper ring are not under pressure, resulting in very low residual friction that remains constant over the entire pressure range.

Seal combination

- Servoseal®

- Functional oil seal

- Wiper ring

Depending on the series, the sealing materials and the guiding system, this system is suitable for:

| Piston speeds | up to 2 m/s |

| Temperature range | from -30 °C to +80 °C |

The sealing system Servoseal® requires a minimum pressure in the chamber of pmin = 50 bar in order to keep the leakage at a low level.

The functional oil flow is discharged into the tank without pressure at the functional oil port; it must not be extracted with vacuum. A preload of the functional oil line up to 5 bar is permissible.

Series 320:

The functional oil ports are internally connected for optional connection.

All other series:

The functional oil ports must be connected externally.