Cushioning with emergency cushioning

Emergency cushioning

An emergency cushioning system in test actuators of the 320 series serves to protect both the cylinder and the entire plant, and is intended in particular to safeguard against unforeseen movements during start-up. It is not suitable for continuous use.

The safety cushioning on test actuators works by throttling the return flow shortly before the end of the stroke movement and is not adjustable.

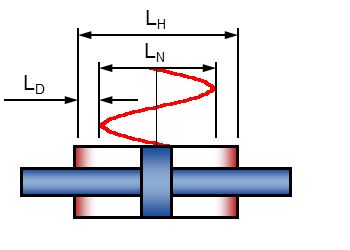

The following stroke terms are distinguished for test actuators:

- Stroke LH: The selected stroke from end position to end position

- Emergency cushioning LD: The cushioning acting before each end position for self-protection of the cylinder. The length of the emergency cushioning is included in the stroke.

- Effective stroke LN: The effective stroke that can be travelled without emergency cushioning

The cushioning can only take effect if the stroke is fully utilised.

When starting from within the cushioning, the piston area is acted upon via the damping gap, which can cause corresponding start-up delays.

The effectiveness of the emergency cushioning depends, among other things, on the moved mass and the travel speed. In the event of overload, i.e. excessive speed or moved mass, damage can occur to the cylinder or to the attached components. The effectiveness must therefore be checked for each application.

A valve block with start-up function can be beneficial here.